Also:

▪ Overcurrent/undercurrent

▪ Earth fault / short circuit

▪ Current asymmetry

▪ Overvoltage/undervoltage

▪ Vibrations

5.7.2 Connecting the temperature monitoring equipment

Submersible motors can be fitted with a temperature sensor for the motor fill

temperature. This is necessary whenever the operating limits of the motor can be

exceeded because of reduced cooling (e.g. ochre build up, increased temperature of

the fluid pumped, etc).

Submersible motors > 1 kV can be fitted with either of the following two options: a

temperature sensor which is inserted into the motor or a temperature sensor which is

fastened directly to the end windings. The option of retrofitting depends on the

motor make and has to be checked. As a standard (order-related deviations are

possible), the sensor has a shielded connection cable of 0.5 mm

2

with 4 cores or of 1.5

mm

2

with 3 cores.

Maximum cable length:

▪ for a cross-section of 0.5 mm

2

= 280 m

▪ for a cross-section of 1.5 mm

2

= 1400 m

For analysing the temperature sensor, a separate analysing device is required.

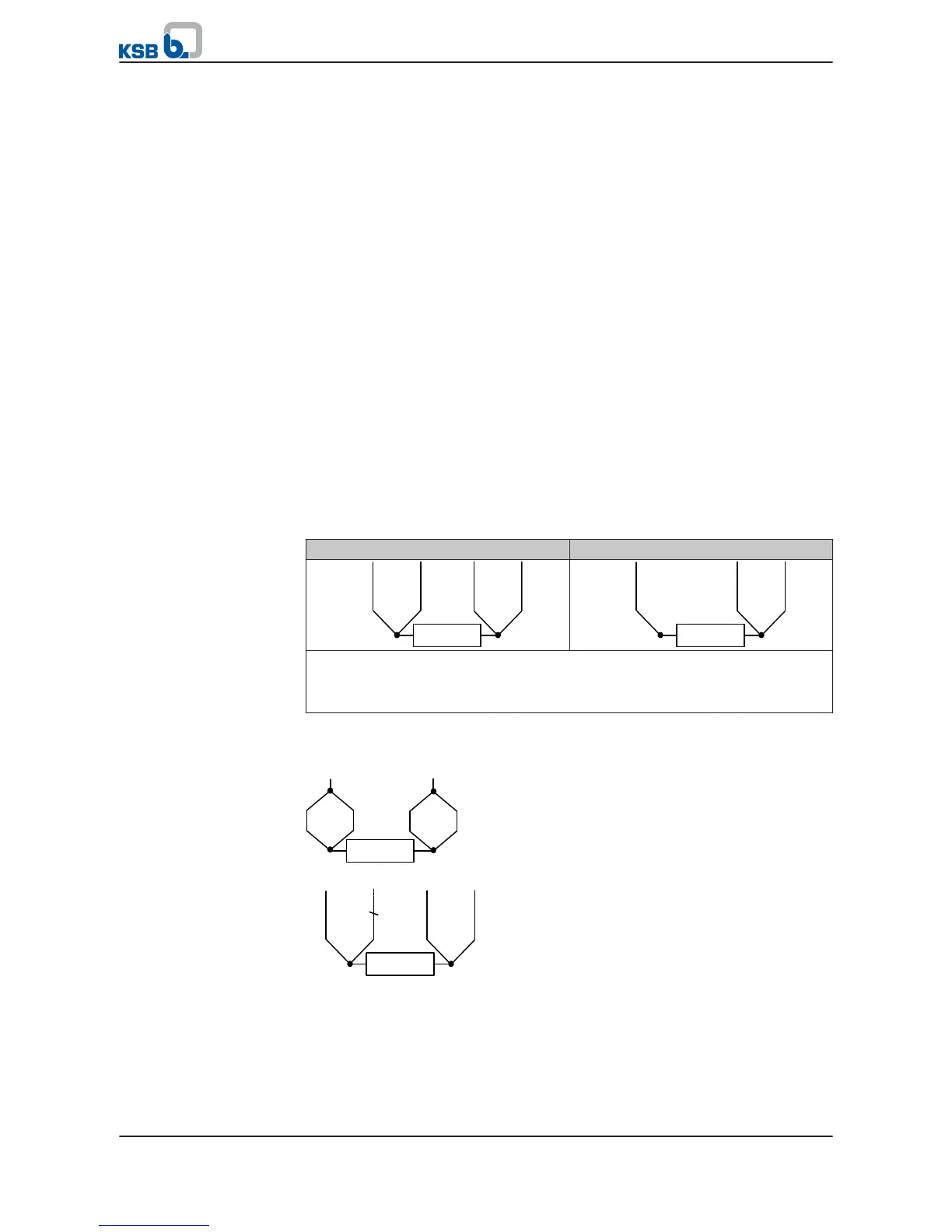

Table 14: Number of cores and corresponding colour codes

4 cores 3 cores

A1 = black core

A2 = grey core

A3 = blue core

A4 = brown core

Connection to the analysing device

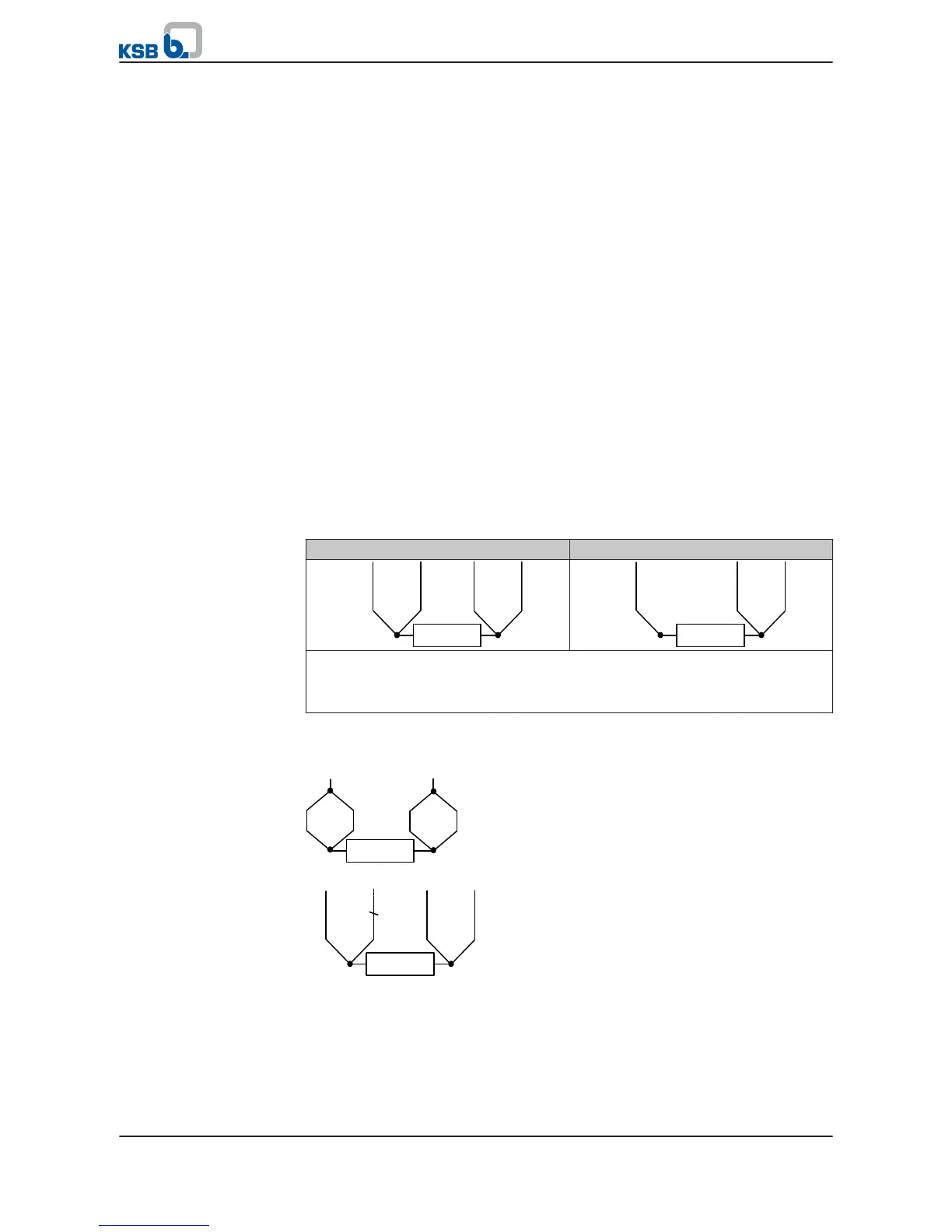

The sensor can be connected by 2-, 3- or 4-wire system.

Loading...

Loading...