PLMNL0243 REV. A, Effective Date: 03/24/16 8 FiberMINI ™ 2.0 Operation Manual

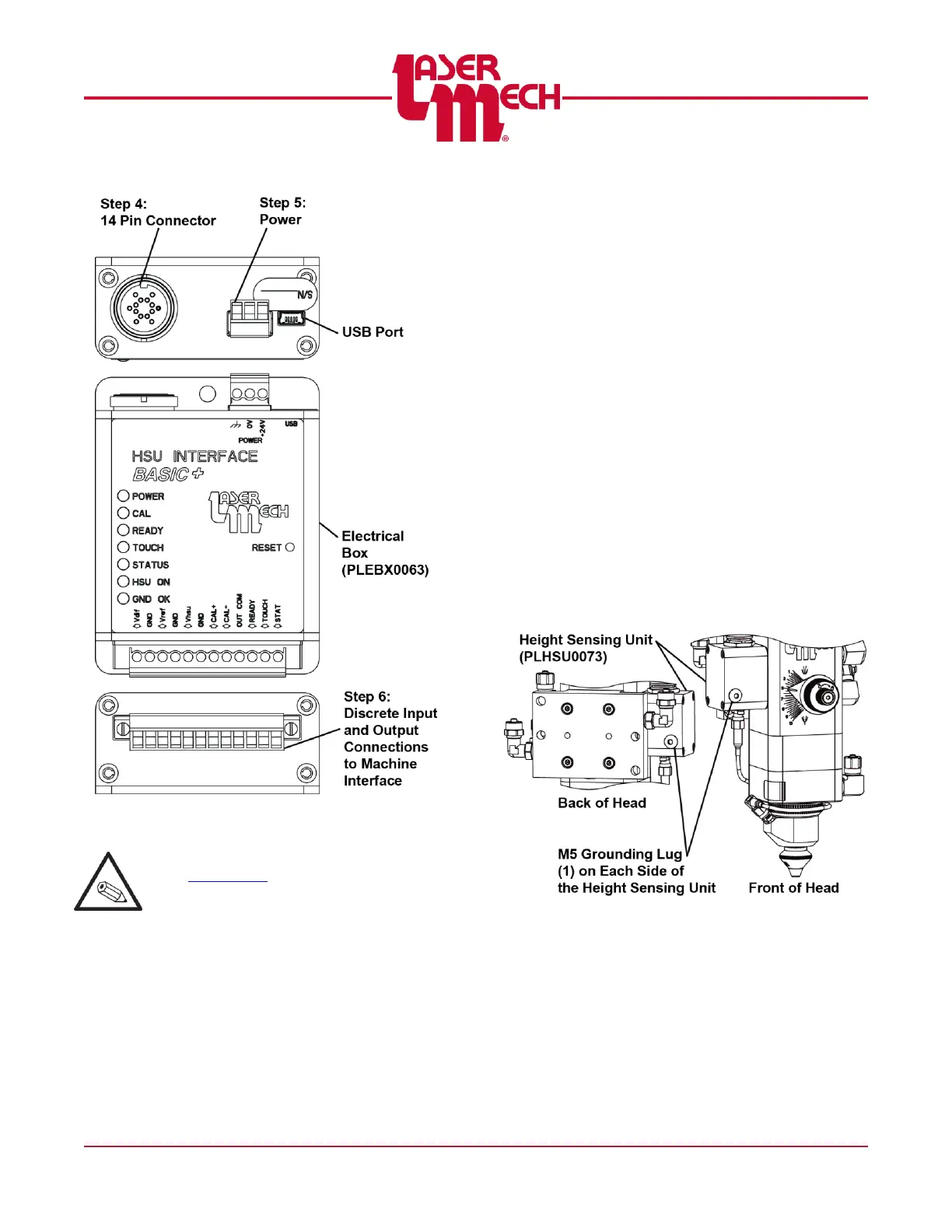

Figure 10

See Appendix B for an interface example.

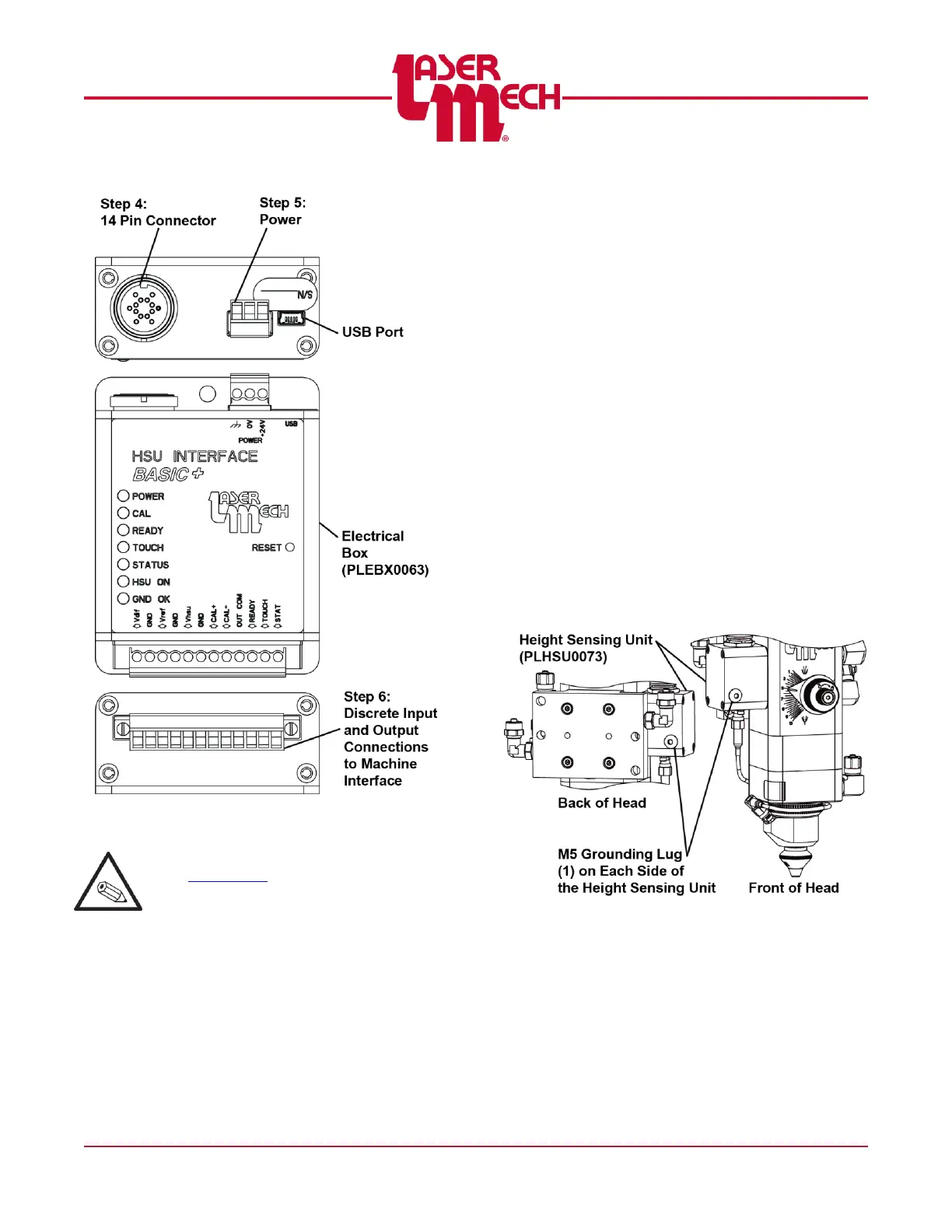

3.2 Electrical Grounding and Noise

The capacitive sensing circuitry contained

in the FiberMINI™ 2.0 cutting head

measures minute changes in electrical

capacitance between the tip and earth-

ground to determine tip-to-part standoff

distance. In order for this circuit to function

properly the part and the cutting head

need to be connected to a good earth

ground.

Ideally the ground should be

established from a ground rod,

approximately 2 meters in length

driven into the ground located near

the base of the machine.

A large gauge (1.6mm diameter or

larger) ground wire should be run from

the ground rod to the part.

Run a separate wire from the ground

rod to the mount of the FiberMINI™

2.0. See Figure 11.

Figure 11

Electrical noise can create sensing issues.

Large electric motors, arc welders and

other devices may be a source of

significant electrical noise. In order to

eliminate this noise it may be necessary to

connect a ground wire to the chassis of

any such device near the process.

Loading...

Loading...