PLMNL0243 REV. A, Effective Date: 03/24/16 1 FiberMINI ™ 2.0 Operation Manual

1 Introduction

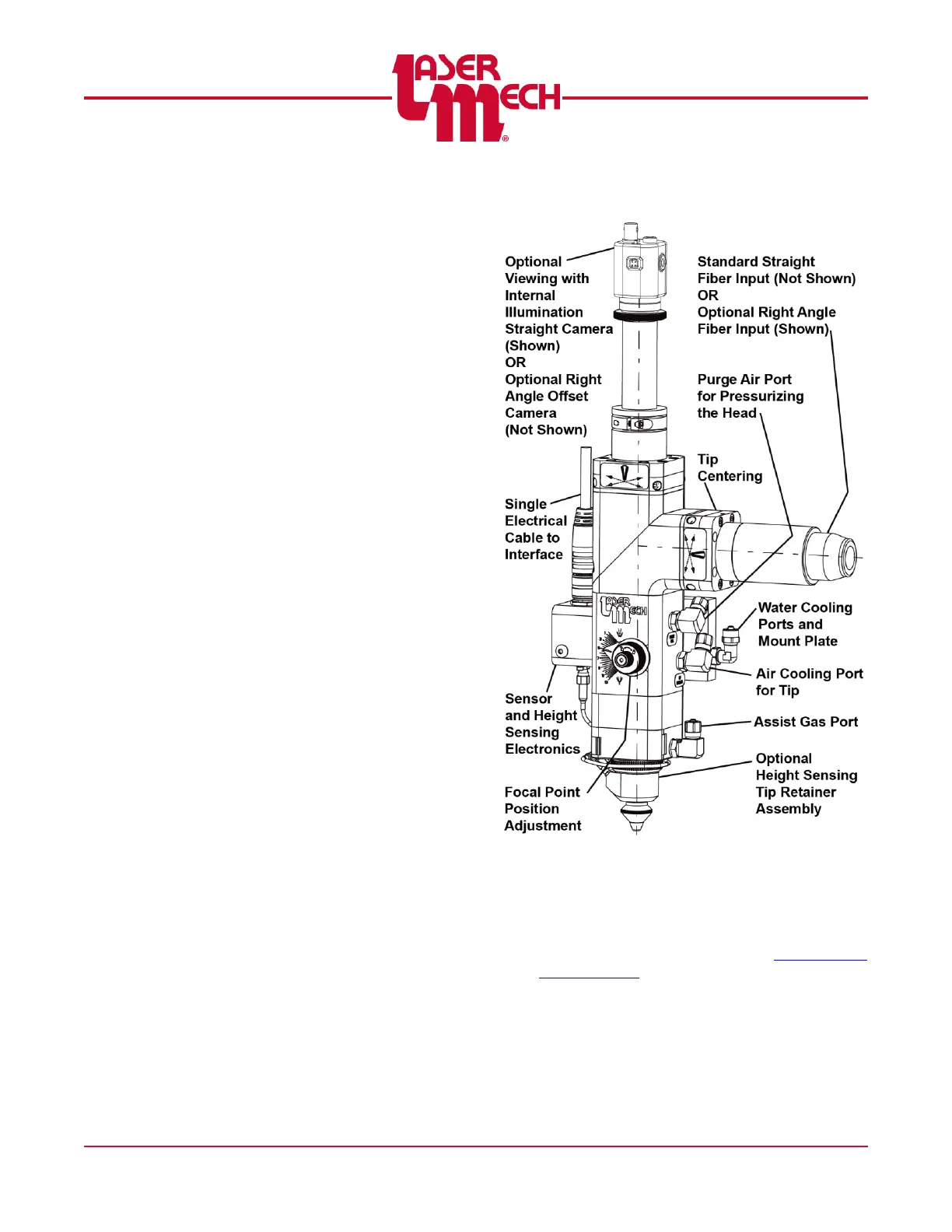

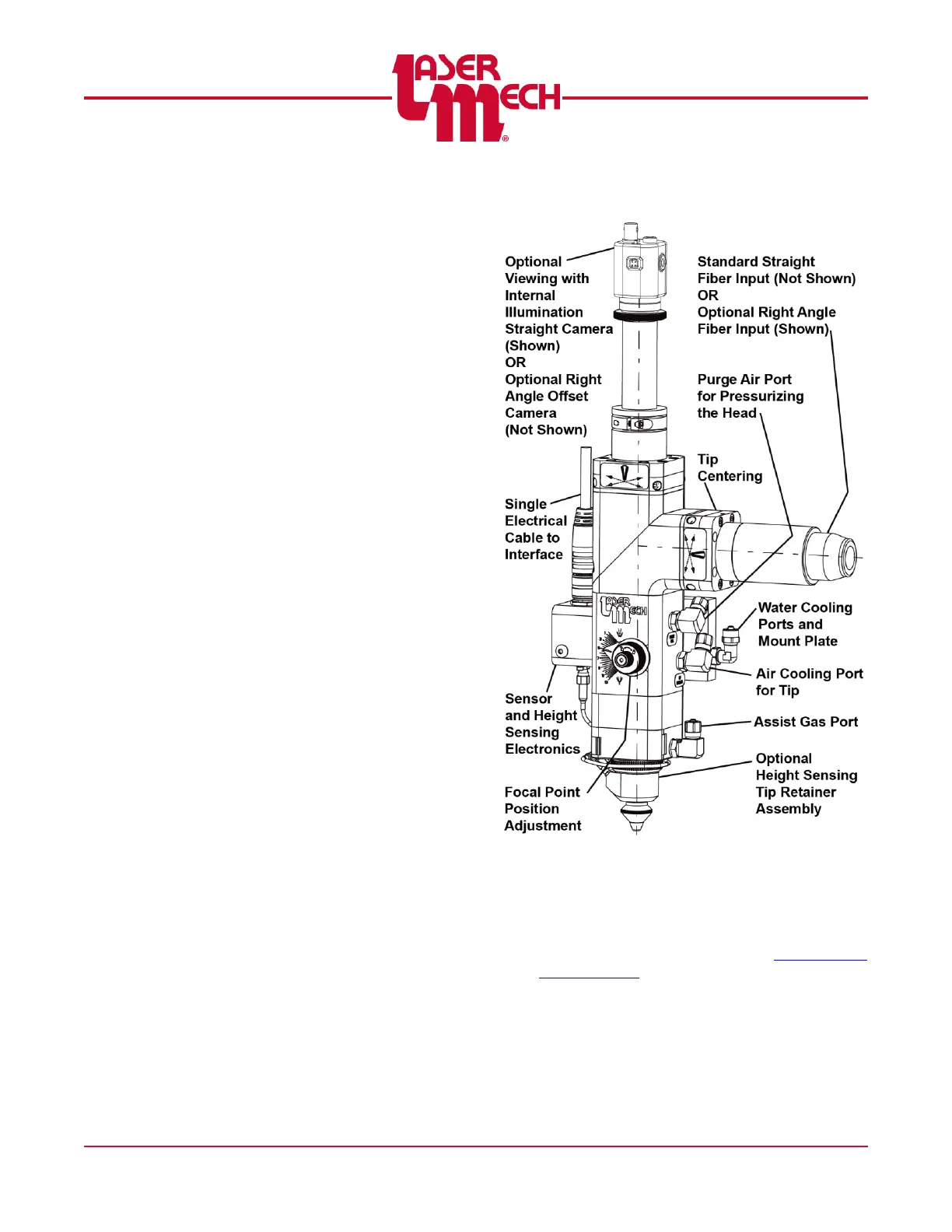

FiberMINI

®

2.0 is available in both straight line

and right angle configurations. Both styles are

simple, yet flexible to optimize the processing

head and the end user’s fiber laser. The head

is capable of cutting a wide range of materials

and available in various welding configurations.

See Figure 1. FiberMINI

®

2.0 can be

configured with:

Straight or Right Angle Fiber Input

Straight, Right Angle, or Offset camera

vision

Internal illumination for all camera options

Coaxial Nozzle connections

Key Features

Flexible design to optimize spot size

Available with and without capacitive height

sensing

13 mm of lens movement to set focus

Quick and easy access to the cover slide

Water and Air Cooling

Smooth assist gas flow

Internal wiring and plumbing for gasses and

coolants

Compact, lightweight design

Compatible with all leading fiber-delivered

laser systems up to 4kW and all weld-

monitoring systems.

Fully Sealed Optical Path

Extra Cooling for Higher Power Rating

Figure 1

This manual explains the steps of installation,

setup, operation and service of the FiberMINI

2.0

®

product line. FiberMINI

®

2.0 is available in

many diverse configurations. See Appendix D –

Configurations and the supplied assembly

drawing to identify the components in your

custom FiberMINI 2.0

®

.

Loading...

Loading...