PLMNL0243 REV. A, Effective Date: 03/24/16 3 FiberMINI ™ 2.0 Operation Manual

Assist Gas

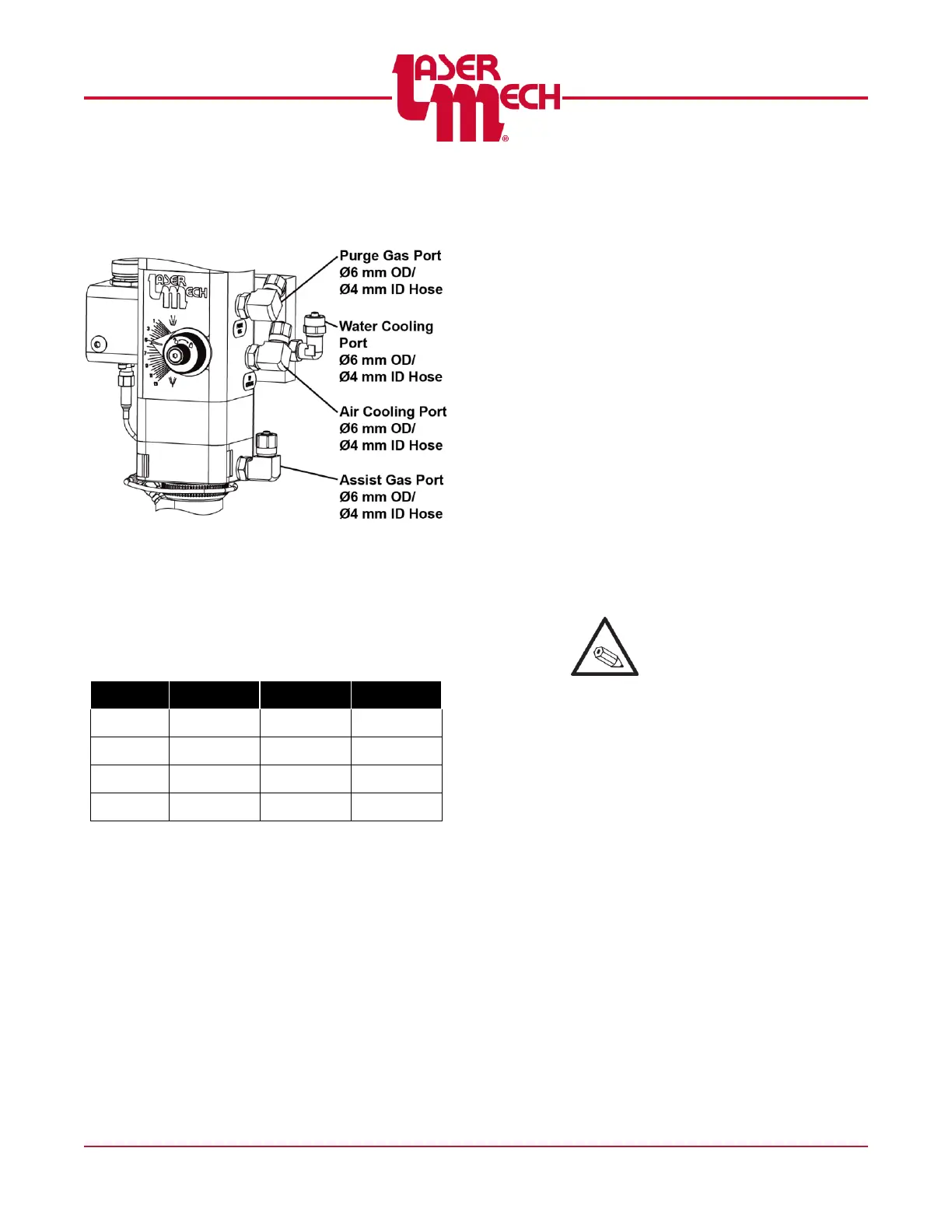

See Figure 5 for location and hose size.

Maximum pressure is 20 BAR.

Figure 5

Impurities in the assist gas such as

hydrocarbons (THC) and moisture (H

2

O)

can damage optics, cause power

fluctuations and result in inconsistent cuts.

See the table below for recommended

assist gas specifications.

Impurities can also be picked up in the

supply lines. Non-metallic materials can

allow oxygen and moisture to permeate

the system and can be a source of dust

and hydrocarbons. Stainless steel lines

and fittings are recommended. Filters that

remove particles down to .01 microns and

purifiers that guard against oil or water

getting into the optical system should be

used.

Regulators with a stainless steel

diaphragm are recommended. Industrial

regulators can aspirate air and the

neoprene diaphragm can be a source of

hydrocarbons.

Purge Gas and Air Cooling

See Figure 5 for location and hose size.

Purge gas pressure is 0.2 – 0.3 Bar

(3.0 – 5.0 psi).

Air cooling pressure is 2.1 – 3.4 Bar

(30.0 – 50.0 psi).

2.3 Cable Bundling

The cables need to be bundled in a

manner which allows complete tool

movement without pinching or pulling of

the cables. The FiberMINI

®

2.0 head was

designed so that all cables input in the

same direction – allowing a sleek, easy-to-

manage bundle.

Cabling should not be tethered to the fiber

input connector or the fiber optic cable.

The manner in which the

cables are bundled is one of

the keys to having a successful

cutting cell. The end user is

responsible for documenting

and training personnel on the

best bundling methods for their

application.

2.4 Fiber Adapter

The purpose of the fiber adapter is to

connect the fiber optic cable to the head.

The fiber input is the interface between

the laser and the cutting head. FiberMINI

®

2.0 will adapt to most industrial fibers.

The key features are:

Several industrial standard styles of

fibers ends are compatible.

o Each of these fibers has a unique

method of securing it to the fiber

input adapter. Refer to the fiber

manufacturer’s information for

specific instructions.

Loading...

Loading...