6 Mounting and connection Lenord+BauerFitting target wheel

62 GEL 2444

English

Check whether the permissible air gap (d) is maintained on the subsequent instal-

lation of the MiniCODER. The value is dependent on the type and tooth wheel

module.

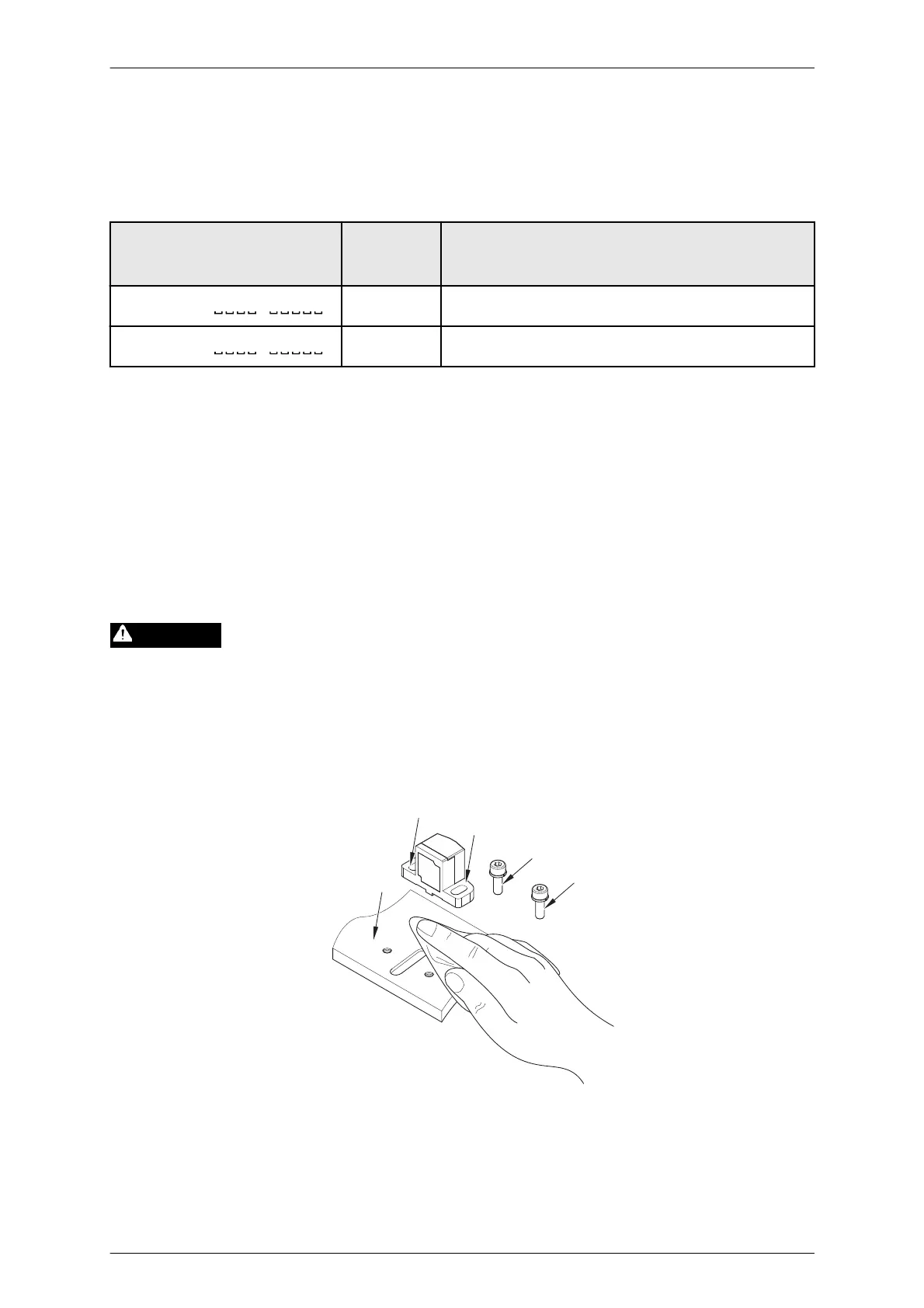

Air gap table

Type Module Air gap d,

preset measure ± distance tolerance

GEL 2444

3 0.3 0.15 mm ± 0.02 mm

GEL 2444

5 0.5 0.20 mm ± 0.03 mm

Mill the recess and make the bores in the mounting carefully and remove chips

completely.

6.2 Fitting target wheel

Mount the target wheel on the shaft; during this process pay attention to the

position of the signal track and reference track.

After mounting, check the mounting tolerances are met.

6.3 Mounting MiniCODER

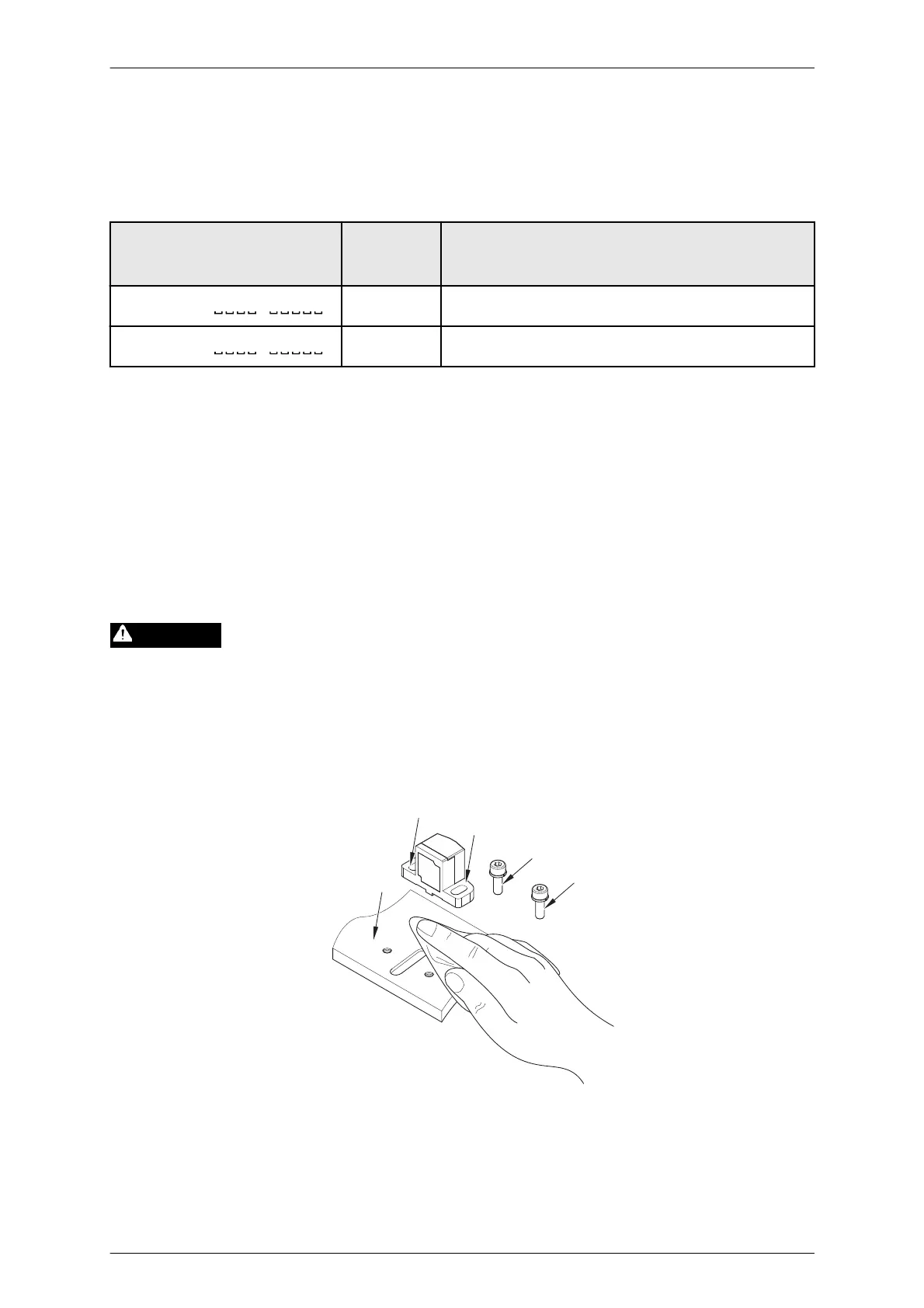

CAUTION

Magnetic field!

● Hold the MiniCODER in such a way as to avoid crushing of fingers

or skin.

6.3.1 Cleaning mounting surfaces

Thoroughly clean the mounting surfaces on the machine and on the MiniCODER

as well as the screws to obtain good electrical conductivity.

Ensure the measuring scale and installation space are free of contamination and

chips from machining.

Loading...

Loading...