User Manual for BPS-2000

www.levitronix.com

PL-4021-00, Rev06, DCO# 21-037

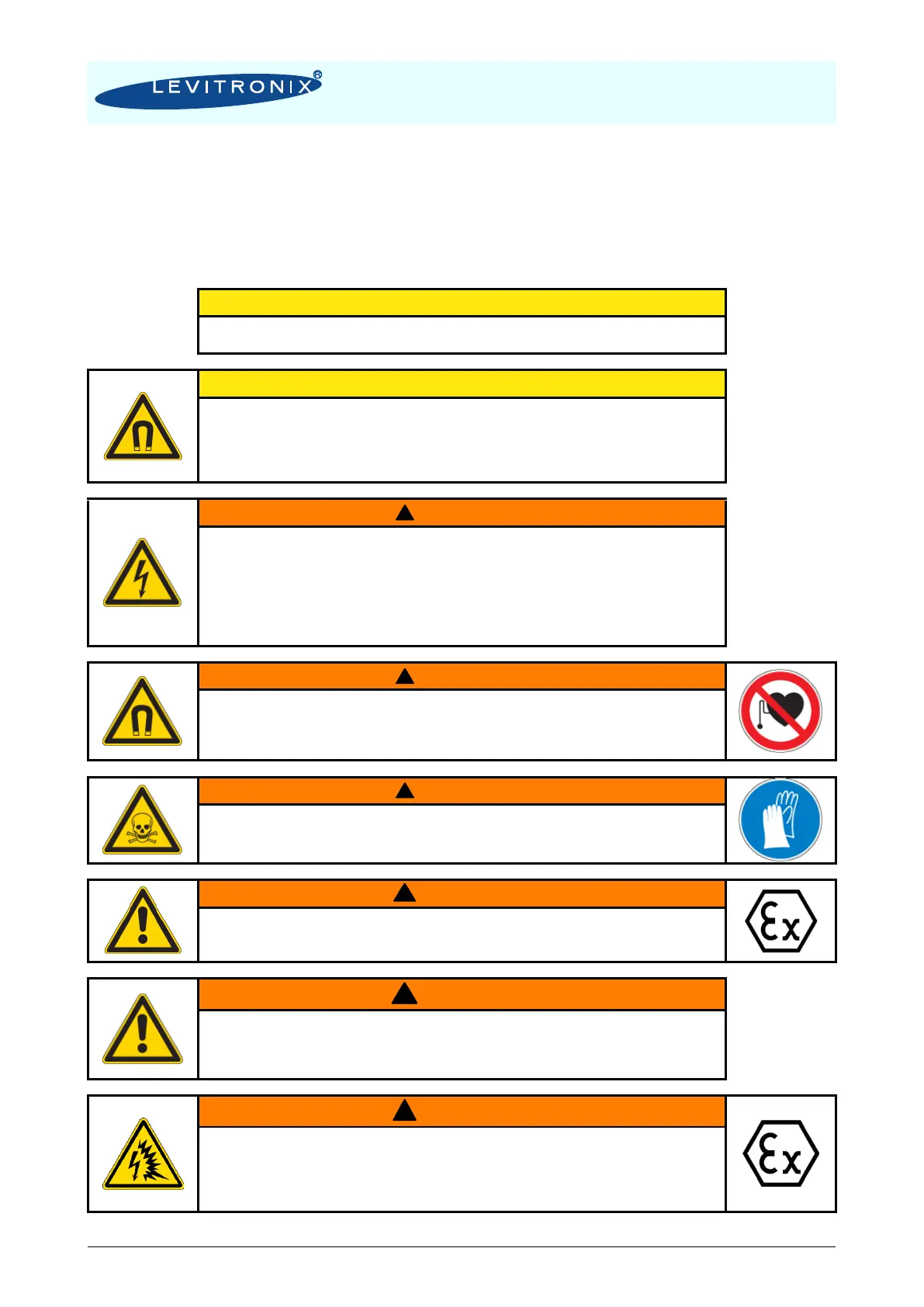

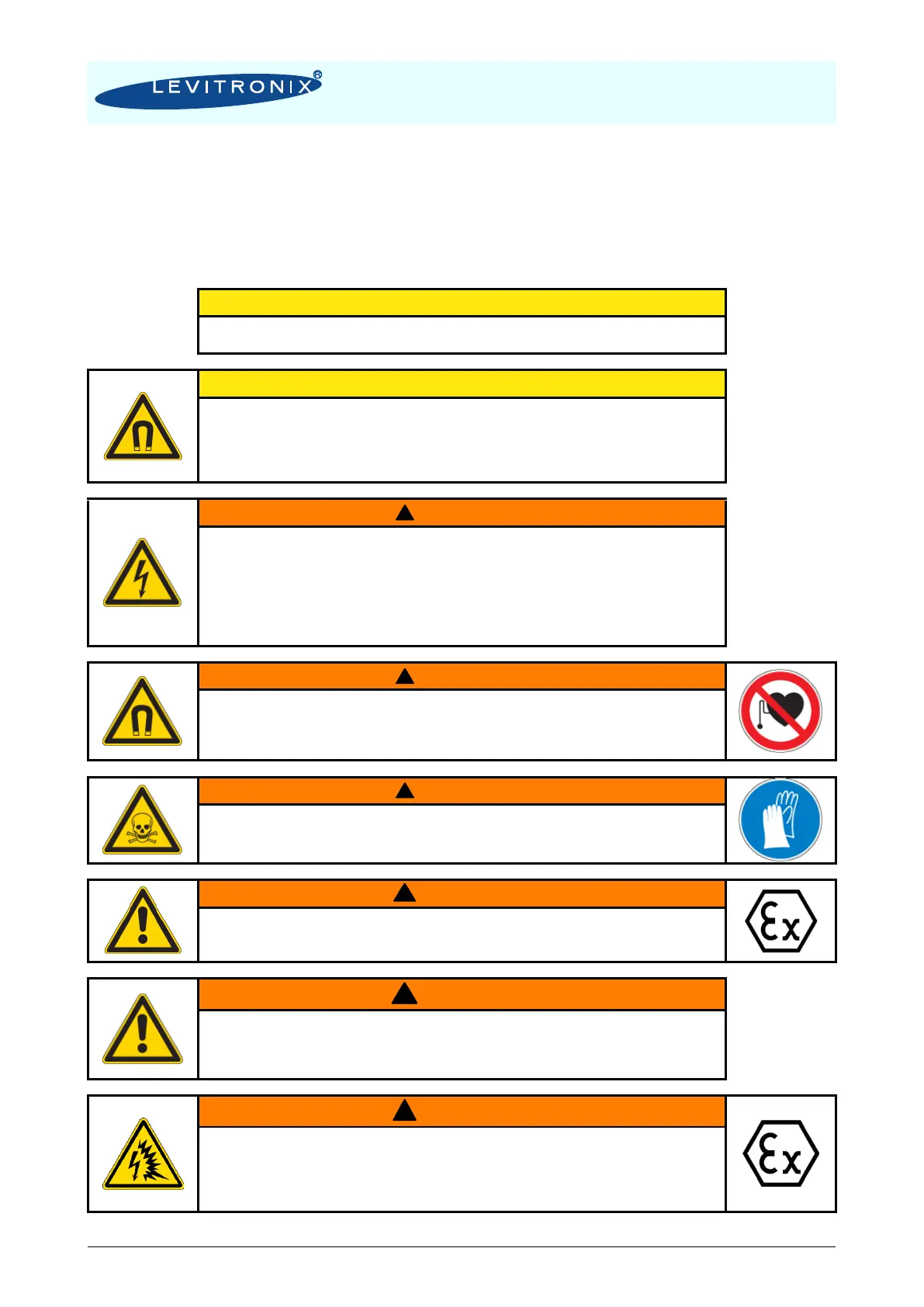

1 Safety Precautions

The BPS-2000 pump system is designed to be used in industrial production machines and equipment

containing hydraulic circuits. Typical applications are Semiconductor and chemical manufacturing equipment.

Installation shall be done by qualified personnel only. Following safety precautions and all “CAUTION”,

“WARNING” and “DANGER” indications in the relevant sections shall be followed.

Do not under any circumstances open the controller or motor. Levitronix

®

does not assume

responsibility for any damage, which occurs under such circumstances.

High magnetic field strength of pump impeller.

The pump system contains a rotor magnet with high field strength. This may alter or damage

the calibration of sensitive electronic devices and measuring instruments in the immediate

surroundings. Keep at a safe distance from the rotor, computers, monitors and all magnetic

data storage media (e.g. disks, credit cards, audio, video tapes etc.)

Hazardous voltage may be present.

The controller must be grounded and placed in a spill protected electrical cabinet. Do not

under any circumstances open the powered controller.

Always isolate the electrical power supply before making or changing connections to the unit.

To remove the power, it is recommended to use an isolating device.

Hazardous voltage is present until 20 sec after switch off. Do not handle the controller during

this time.

High magnetic field strength of pump impeller.

The pump system contains a rotor magnet with high field strength. Pace maker may be

influenced and magnetic forces may lead to contusions. Keep distance to pace makers and

handle impeller with care.

TOXIC CHEMICALS may be present.

When using the system to pump chemicals skin contact and toxic gases may be hazardous

to your health. Wear safety gloves and other appropriate safety equipment.

Motors for ATEX/IECEx and Hazardous Location applications: only specific types of motors

LPM-2000 are classified for the use in Ex or Hazardous classified locations. Refer to the

corresponding section in the manual.

Do not miss-match the power extension cables for connection of the motor to the controller

of the BPS-BPS-2000 as this may destroy the controller.

The BPS- -

BPS-2000 -

Do Not Operate the Metallic Pump Head Dry!

In case of failure in dry running conditions, the failing rotating impeller of the metallic pump

head can cause sparks. Precautions must be taken, to avoid explosive atmospheres within

the pump head under any circumstances. Dry running must be avoided, and the pump head

must be filled with liquid at any time while the impeller is rotating.

Loading...

Loading...