User Manual for BPS-2000

www.levitronix.com

PL-4021-00, Rev06, DCO# 21-037

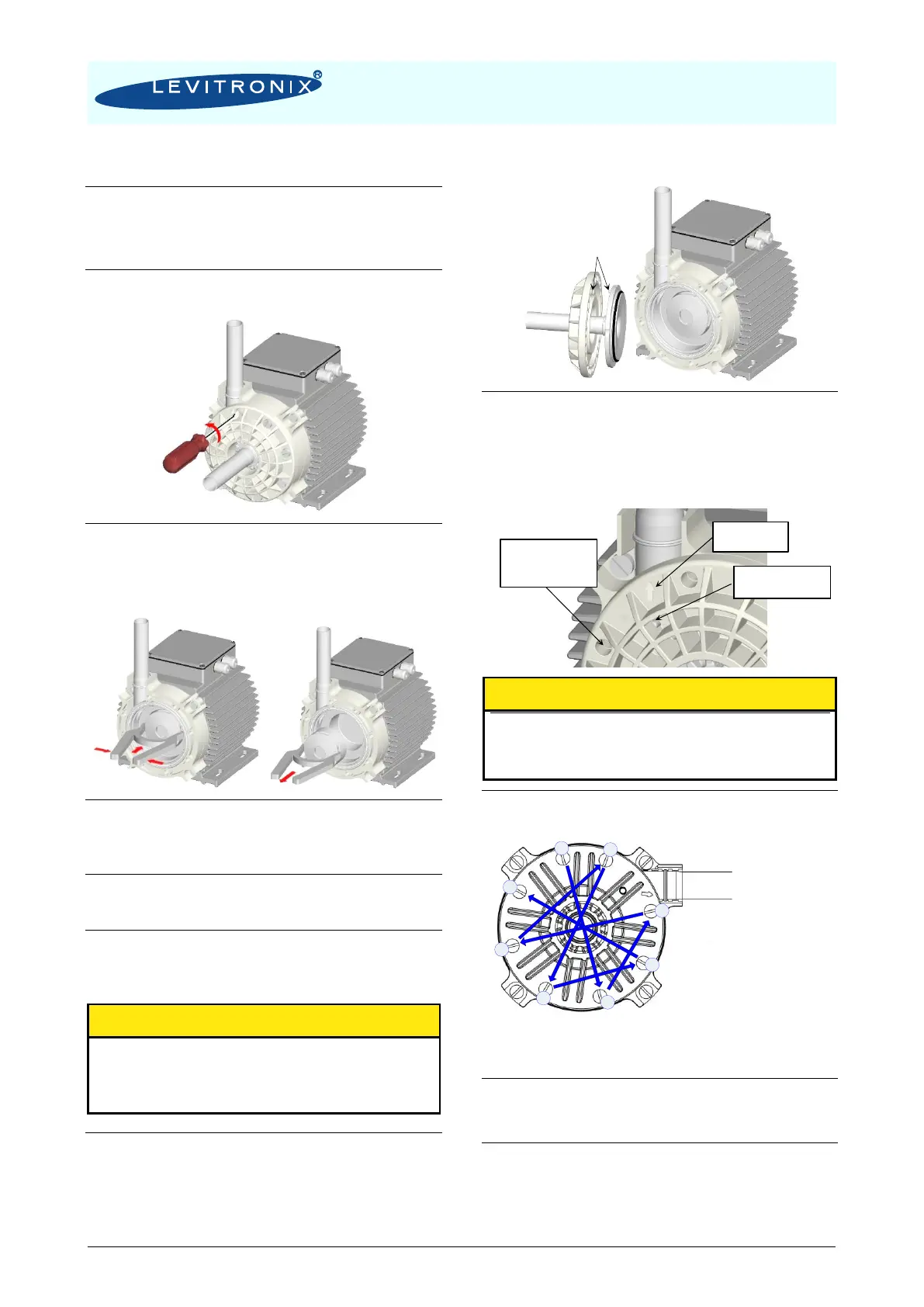

6.2.3 Instructions for Replacement with PFA+PP Pump Housing

1. Power down the pump system and remove the

AC power. Let the motor and pump head cool

down to a workable temperature before the

impeller can be exchanged.

2. Unscrew the lid of the pump head and remove it

along with the sealing ring.

3. Remove the impeller with the Impeller

Exchange Tool. Hook the claws of the Impeller

Exchange Tool into two opposing vanes of the

impeller.

4. Inspect the wet area of the pump head

carefully. In case of material damage, also

replace the pump housing.

5. Place the new impeller into the pump housing

using the Impeller Exchange Tool.

6. If necessary, remove the existing O-Ring and

gently press the new O-Ring into the lid of the

pump casing.

Use always the specified O-Ring type. If necessary,

consult the Levitronix

®

Technical Service Department.

Do NOT twist or roll the O-Ring and avoid to adding

scratches or particles as this may cause leaking.

7. Align the PFA lid with the PP lid of the

reinforcing casing and assure the PFA

alignment pin fits in to the according hole of the

PP lid.

8. Press the lid with the O-ring flush into the

bottom of the pump casing. Check if the screw

holes of the PP reinforcing lid are properly

aligned with the thread holes of the PP

reinforcing base and that the arrow of the PP lid

is showing to the outlet.

Do not use the pump head screws to press the lid into

the pump housing bottom. This might lead to

distortions of the O-ring, which affects the sealing and

hydraulic performance.

9. Tighten the 8 pump housing screws by

following torque increasing sequences:

Note: These are typical values for the standard pump head LPP-

2000.22. Refer to the relevant pump head specification drawings for

other configurations, which may have different values.

10. Start up the system and check if the impeller is

rotating properly and the pump head doesn’t

leak.

11. If the pump head leaks make sure the lid and

the O-Ring are properly pressed into the bottom

of the pump casing. It may be necessary to

change the O-Ring if it has been damaged.

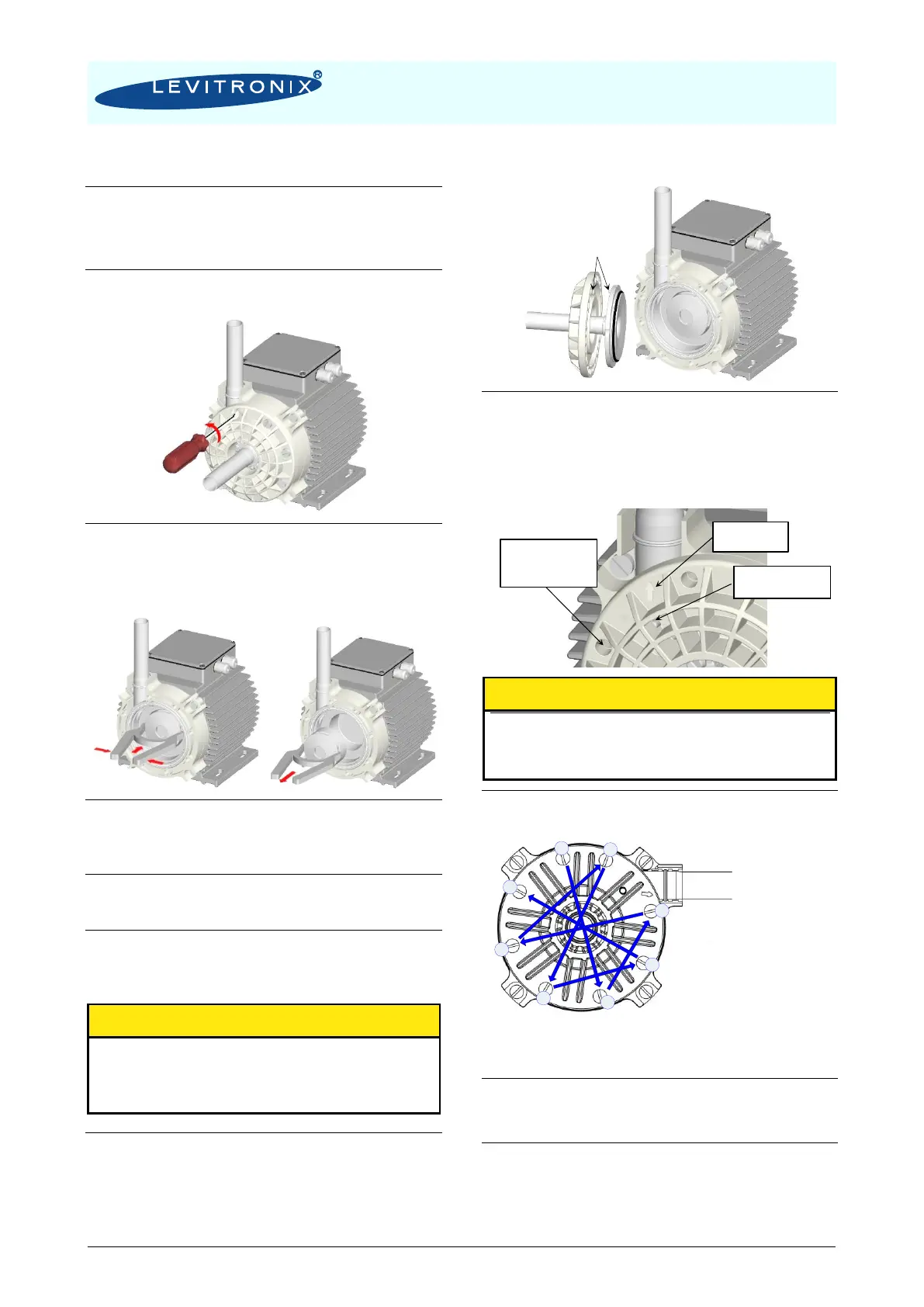

Fit PFA lid pin

into PP lid hole

PP lid holes

aligned with thread

holes of PP base

PFA lid pin

fits into PP lid hole

Tightening Sequence A: 100 Ncm

Tightening Sequence B: 250 Ncm

Tightening Sequence C: 250 Ncm

Tightening Sequence D: 250 Ncm

Loading...

Loading...