Lexmark T65x and X65x Mono Product Study Guide Rev 1.47

For Training Purposes Only 6/3/2009

15

Alignment assembly – skew adjustment

Do the alignment assembly adjustment whenever you replace the alignment assembly. Always print a

copy of the Quick Test Page before making any adjustments to the alignment assembly reference

adjustment screw. When replacing the alignment assembly, it is necessary to back the reference

adjustment screw out far enough to remove the old assembly and install the new one.

• If you are replacing the alignment assembly, go to step A.

• If you are only adjusting the reference adjustment screw, go to step B.

Step A

Print a copy of the Quick Test Page and check the margin adjustments printed on the test page. These

settings should be within the range specified in “REGISTRATION” shown below:

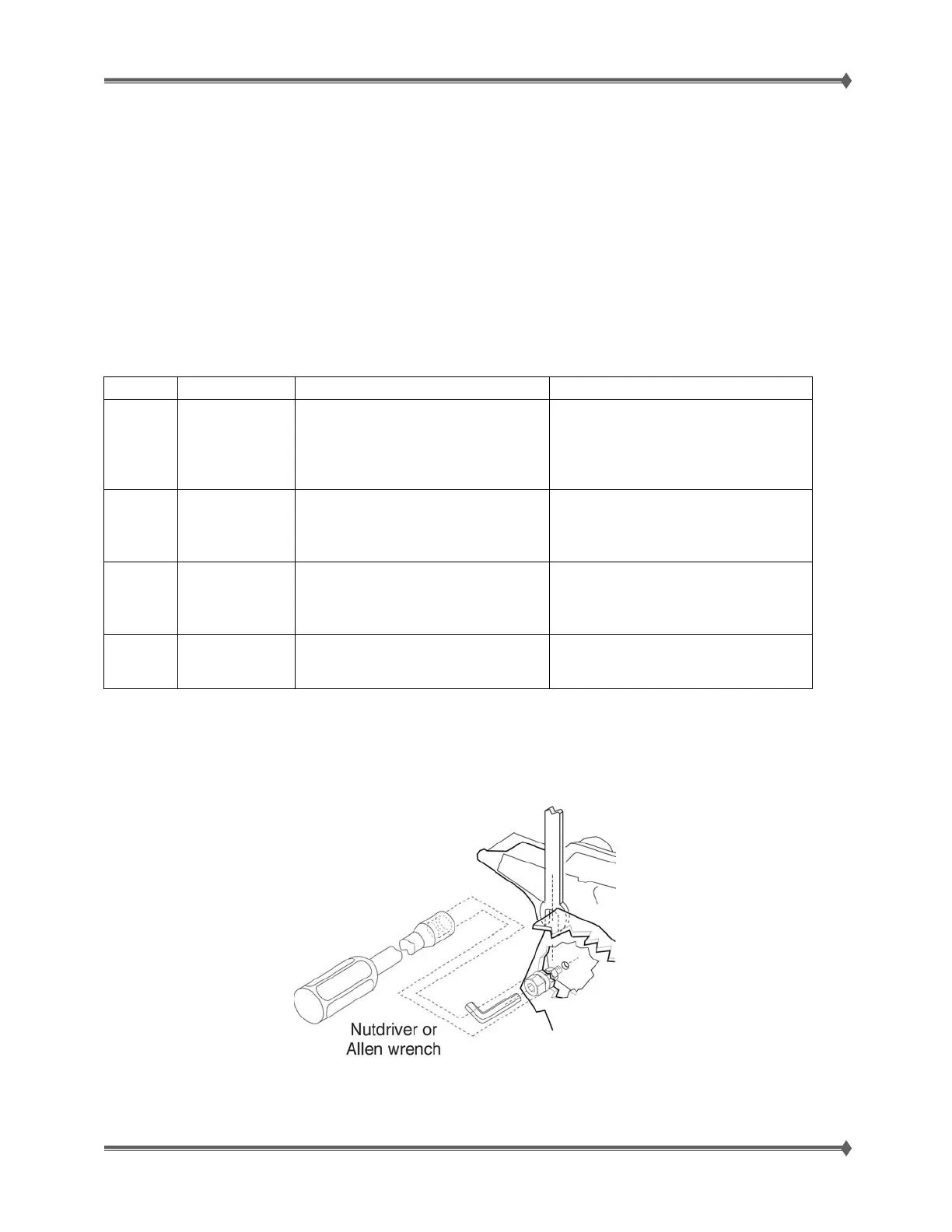

Variable Description Value Direction of change

T= Top margin -25 to +25 Each increment causes

approximately 4 pels shift (at 600

dpi).

A positive change moves the image

down the page and increases the

top margin. A negative change

moves the image up and decreases

the top margin.

B= Bottom margin -20 to +20 Each increment causes

approximately 0.55 mm shift in the

bottom margin.

A positive change compresses the

image so it appears to move down

the page and a negative change

moves the image up.

L= Left margin - -25 to +25 A positive change moves the image

to the right, and a negative change

moves the image to the left. No

compression occurs.

M= Right margin - 99 to +99 A positive change moves the image

to the right, and a negative change

moves the image to the left.

Do the reference adjustment if you are sure the margins are set correctly.

1. Loosen the locknut on the inside rear of the alignment assembly.

2. Remove the two screws holding the alignment assembly to the left side frame.

3. Back the reference adjustment screw out far enough to allow the alignment assembly to be removed

from the printer. It is not necessary to completely remove the screw.

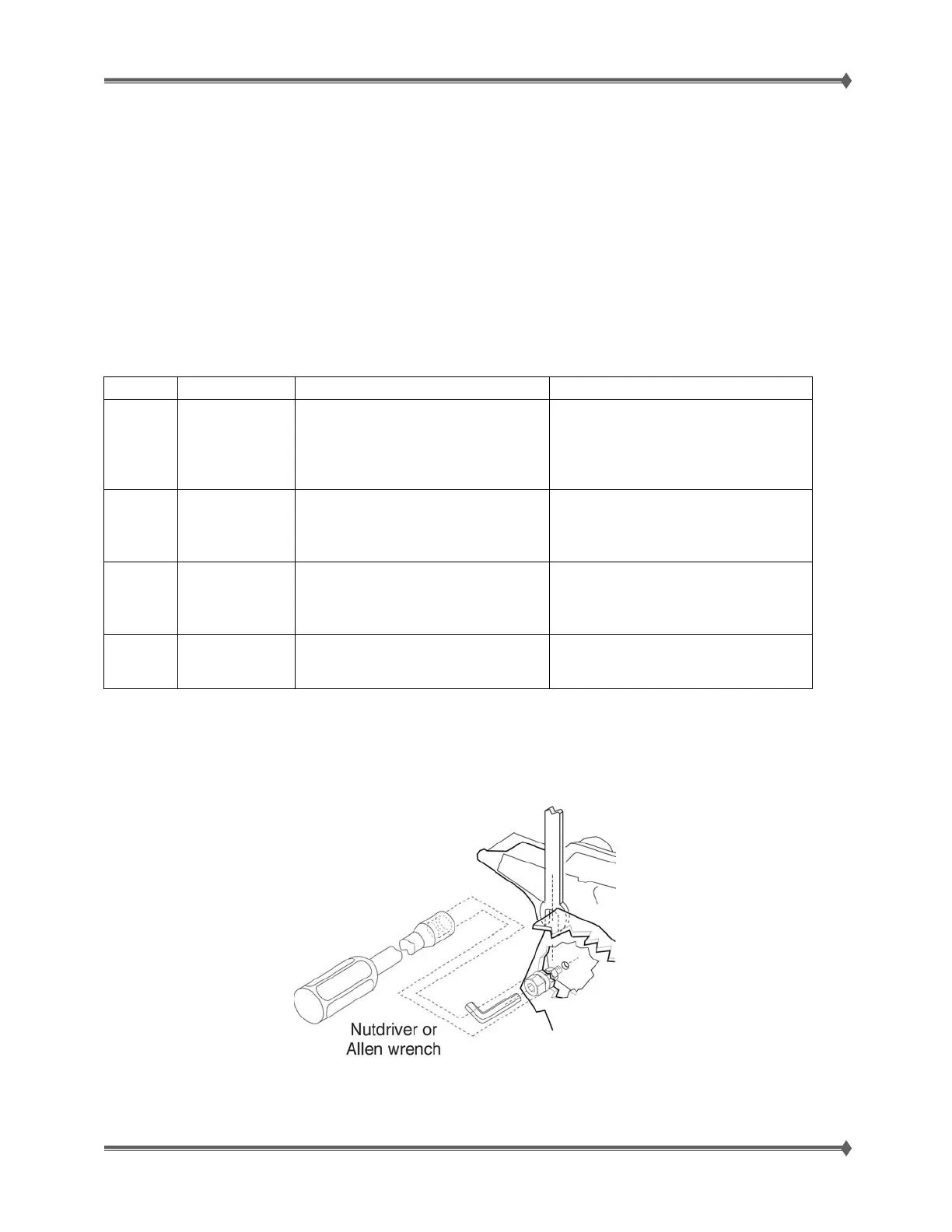

4. Install the new alignment assembly. Turn the reference screw clockwise with a 7 mm nut driver or M3

Allen wrench until it touches the back of the reference plate, and tighten the nut with a 5.5 mm

wrench.

Loading...

Loading...