13

Lower Horizontal Cutter

Before opening the planer’s cover (6), ensure that the power

is disconnected and that the cutter heads are not rotating.

Use protective gloves. This is especially important when

you are loosening screws that are tightly screwed, or when

you are tightening the screws (see Safety Instructions). Be

careful of the planing knives. You can easily get cut by those,

even when touching them lightly.

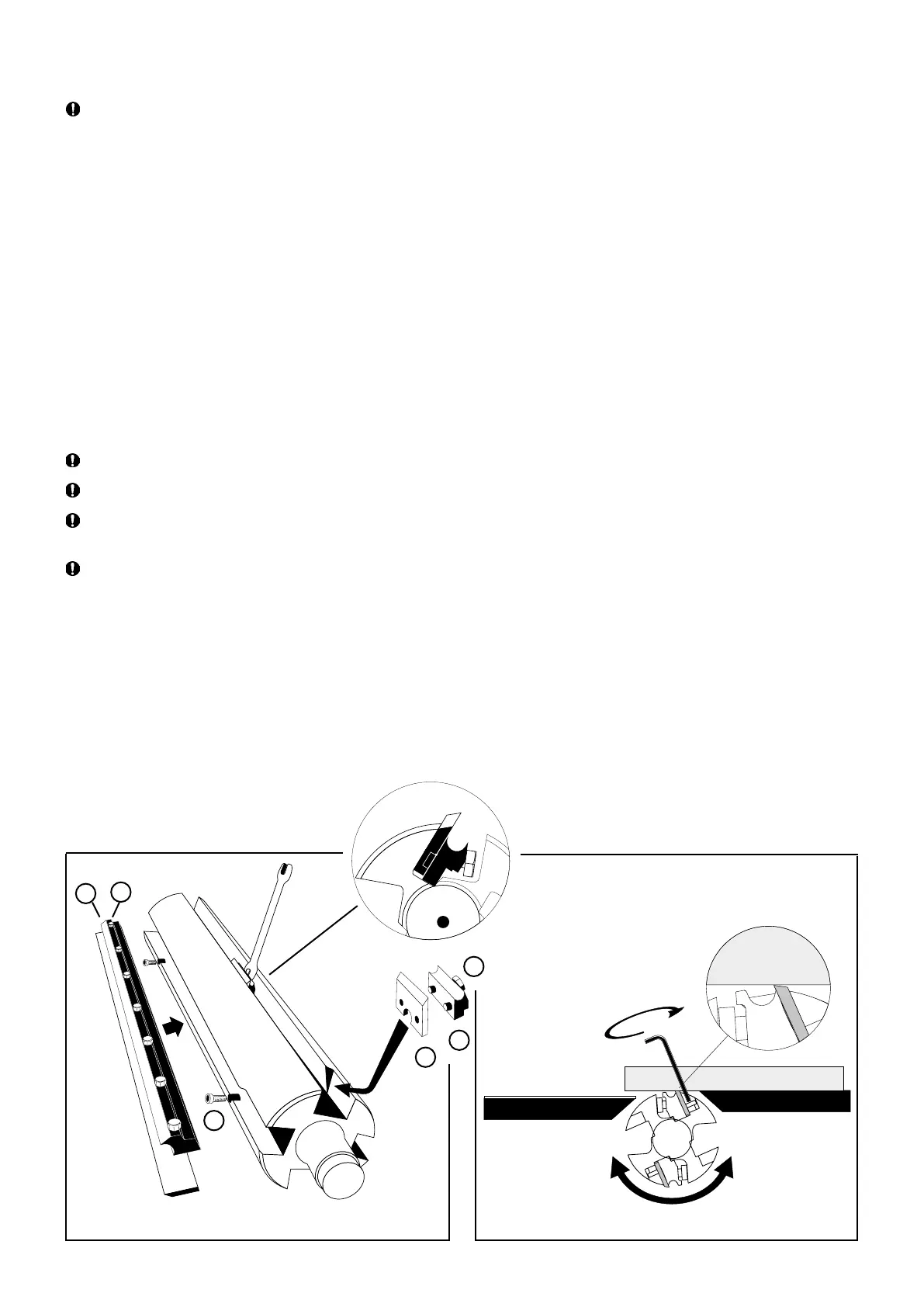

The lower cutter is located in the machine table on the in-

feed side of the machine. On delivery, two planing knives are

mounted in two of the cutter head’s knife slots (planing knife

300 mm HSS, ref. no. 7000-002-8300). Two additional planing

knives, or moulding knives, can be mounted in the two empty

knife slots.

After you have adjusted or replaced planing knives or moulding

knives:

Make sure that there are no tools left inside the machine.

Make sure that all screws are reliably tightened.

Make sure that the cutter heads can rotate freely before

closing the protective cover.

Do you remember the safety instructions on pp.4-5?

Adjusting the lower horizontal cutter

The planing knives in the lower horizontal cutter should be set

so that they are level with and parallel to the machine table.

- Using a 10 mm spanner (supplied), loosen the chip breaker’s

lock screws (B), which are in the track between the chip

breaker (A) and the cutter head. After this the knife can be

raised or lowered with the help of the two recessed adjusting

screws (4 mm Allen) (C) next to the cutter’s knife slot. Use

a 4 mm Allen key (supplied). The knives should protrude 1

mm in order to t against moulding knives from Logosol.

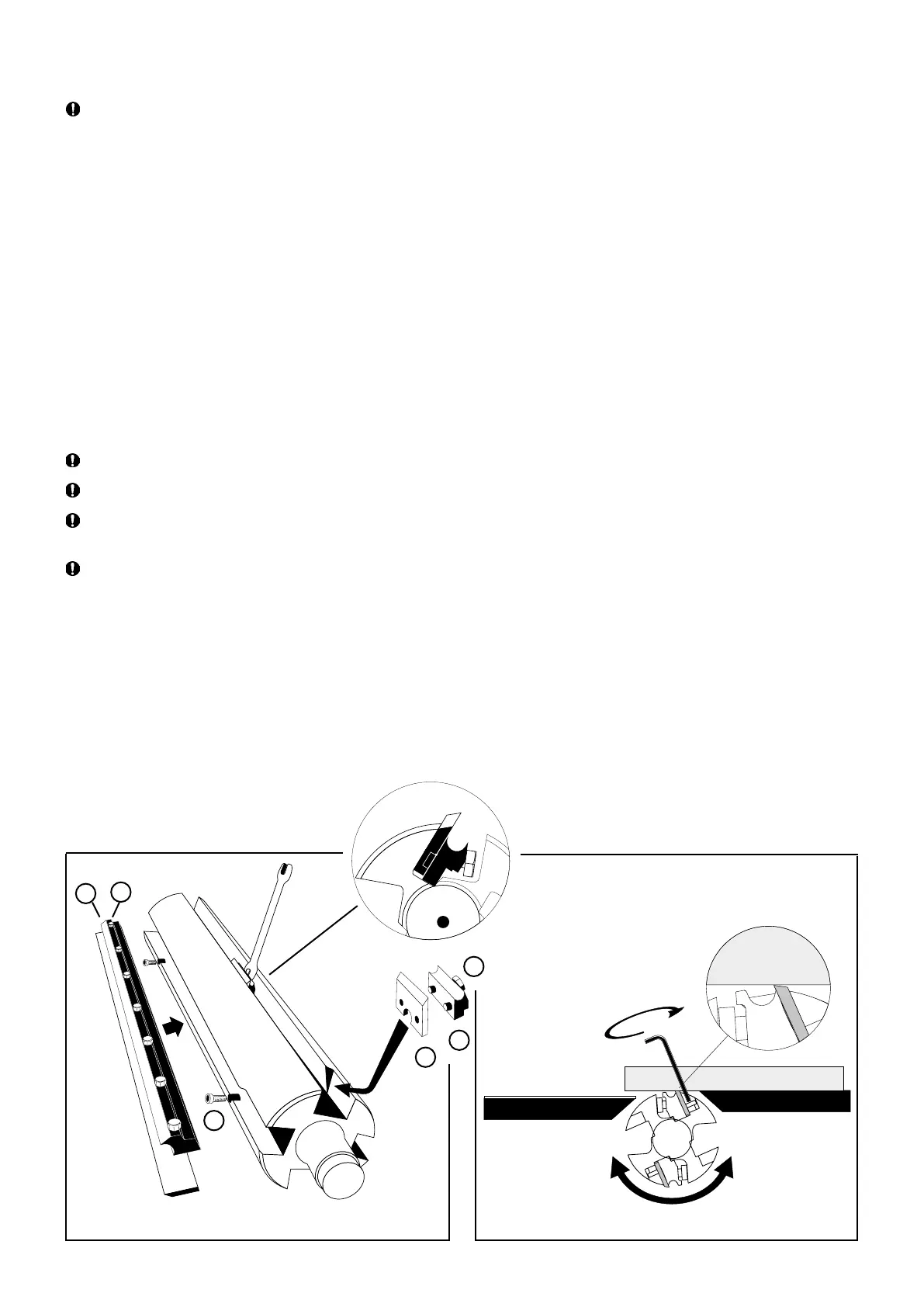

- Check the knife level in the cutter head by placing a piece

of a planed board on the machine table behind the cutter.

The knives should then touch the board (see the picture

below). You can also use a magnetic adjuster (magnetic

adjuster, lower cutter, ref. no. 7500-001-0051): Loosen the

chip breaker’s lock screws, and screw down the knife’s

adjusting screws a couple of turns. Rotate the cutter head

so that the planing knife comes in its uppermost position.

Place the magnetic adjuster at and shaped as a ‘V’ on the

machine table behind the cutter, so that the edge of the knife

comes directly under the magnets of the magnetic adjuster.

Screw up the adjusting screws until the knife is lifted by the

magnet and by this gets the right height. Tighten the lock

screws and then carefully screw down the adjusting screws

so that they x the knife in this position.

- Tighten the lock screws (which x the knives) anticlockwise.

Tighten carefully at rst. Start from the sides, and move to

the next until you reach the middle, then retighten all screws

the same way.

- Carefully tighten the adjusting screws until they touch the

bottom of the indentations of the knives. If these screws are

screwed too tight, the knife will crack.

A

B

C

D

E

F

Loading...

Loading...