16

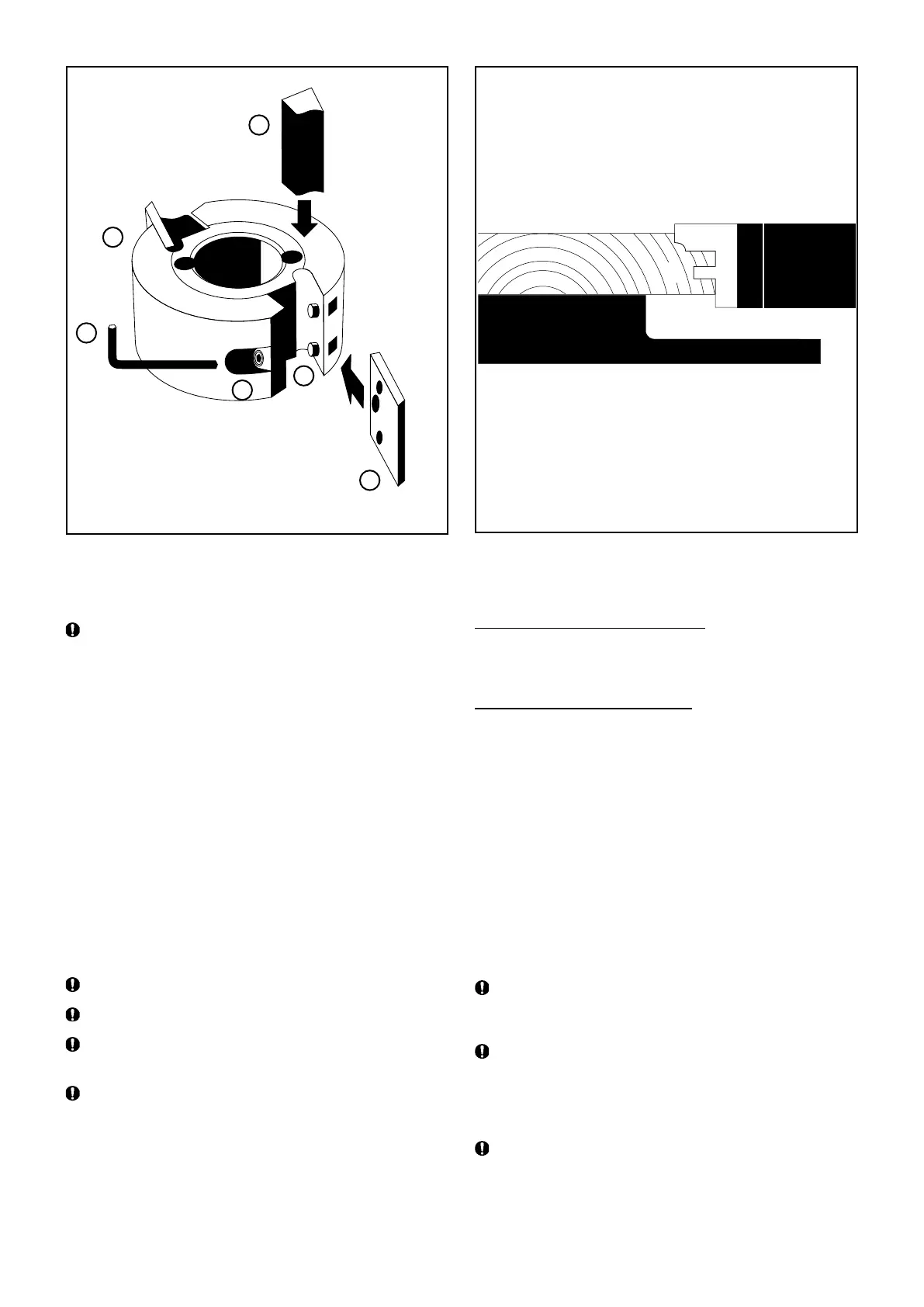

Side cutters

Before opening the planer’s cover, ensure that the power is

disconnected and that the cutter heads are not rotating. Use

protective gloves. This is especially important when you are

loosening screws that are tightly screwed, or when you are

tightening the screws (see Safety Instructions). Be careful

of the planing knives. You can easily get cut by those, even

when touching them lightly.

The side cutters are located at the sides of the machine table.

The spindle axles are 30 mm (1.2”) in diameter, which is a

standard dimension. On delivery, the machine is equipped

with two universal cutter heads with planing knives, which can

readily be replaced by moulding knives. For safety reasons,

the cutters use conventional milling, i.e. the work piece is fed

against the rotation direction of the cutter. Due to this, the lock

nut and the spindle of the movable side cutter have to be left-

hand threaded.

After mounting of the side cutters:

Make sure there are no tools left inside the machine.

Make sure that all screws are reliably tightened.

Make sure that the cutter heads can rotate freely before

closing the protective cover.

Do you remember the safety instructions on pp.4-5?

Removing the side cutters

Cutter 2 (right side, stationary cutter): Using a 30 mm spanner

(supplied) and an adjustable spanner, loosen the nut on the

spindle. Screw off the nut and remove the cutter and spacers,

if any.

Cutter 3 (left side, movable cutter): Turn the crank so that the

cutter comes to its front position. The nut is loosened in the

same way as on cutter 2, with the only difference that the nut

of cutter 3 is left-hand threaded and therefore screwed in the

opposite direction.

Tip: Loosen the nuts on the side cutters by screwing them in the

same direction as their respective cutter rotate.

Replacing knives

Loosen the lock screw (B) with a 4 mm Allen key (C) (supplied),

and remove the chip breaker (D). Remove the knife (E) from

the dowel pins (F). Insert a new knife, and screw the lock

screws tight.

Make sure that the knives are turned the right way when

mounting them in the cutter head. The edge should be turned

towards the chip breaker.

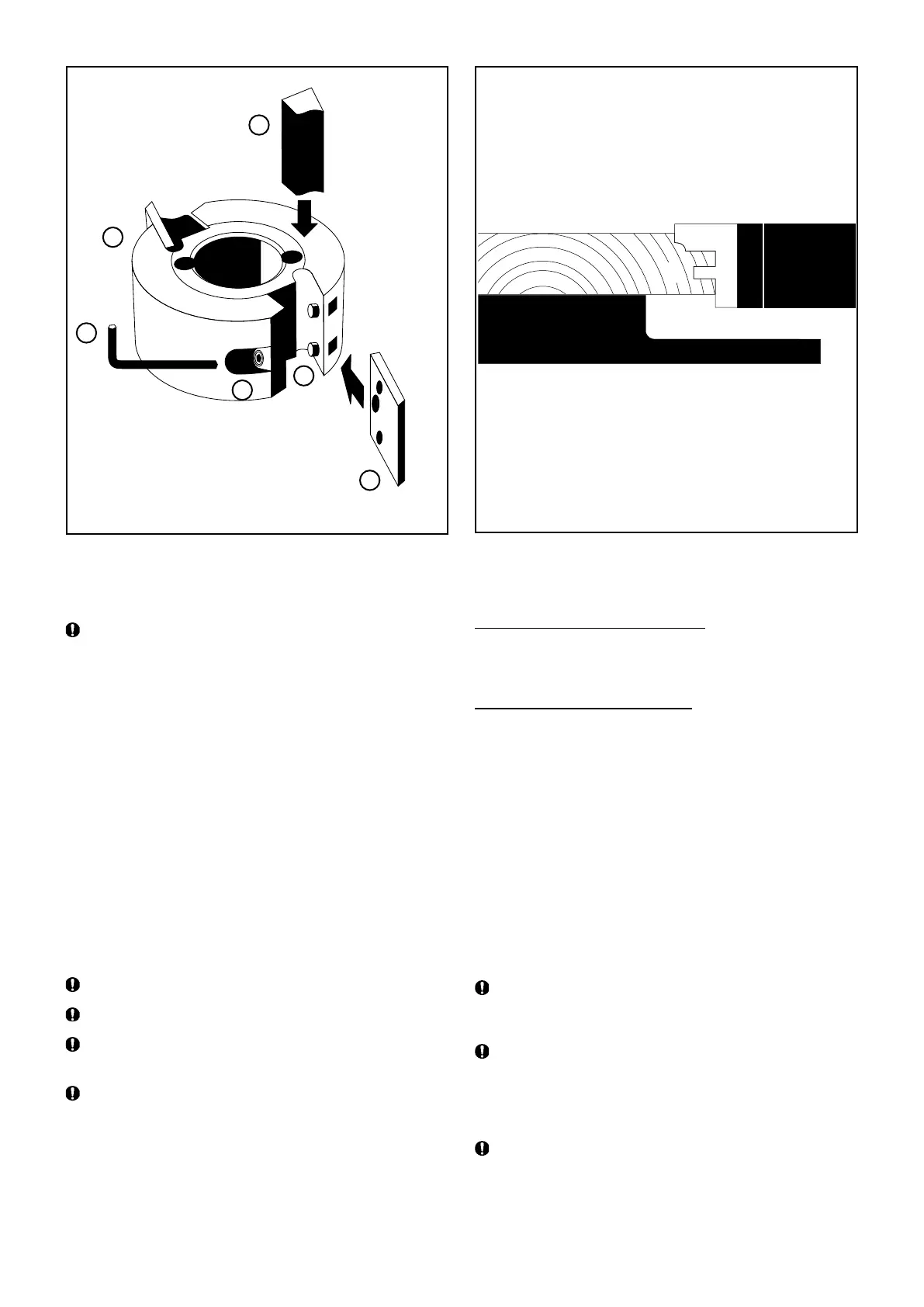

Make sure that the rust protected chip deector before the

movable cutter does not run the risk of getting bent by the

unplaned edge of the work piece and due to this comes in

contact with the cutter. Be extra cautious when work pieces

of various widths are being processed.

Make sure that the cutter head can rotate freely, and

that there is a space of approx. 5 mm (0.2”) between the

outermost cutting diameter of the cutter and the chip deector

that works as a chip barrier behind the movable cutter.

C

A

D

B

F

E

6

7

8

Loading...

Loading...