33

Troubleshooting

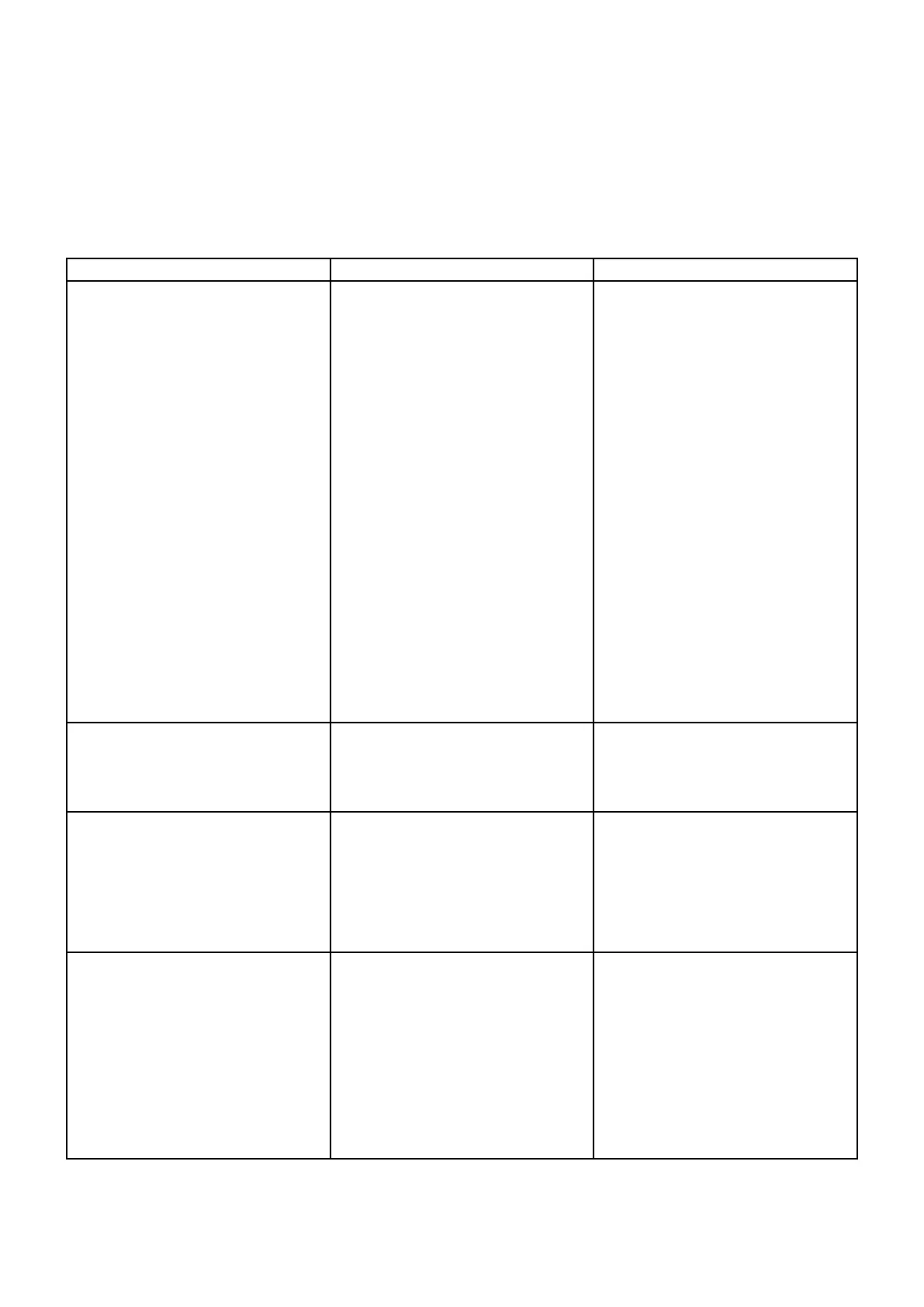

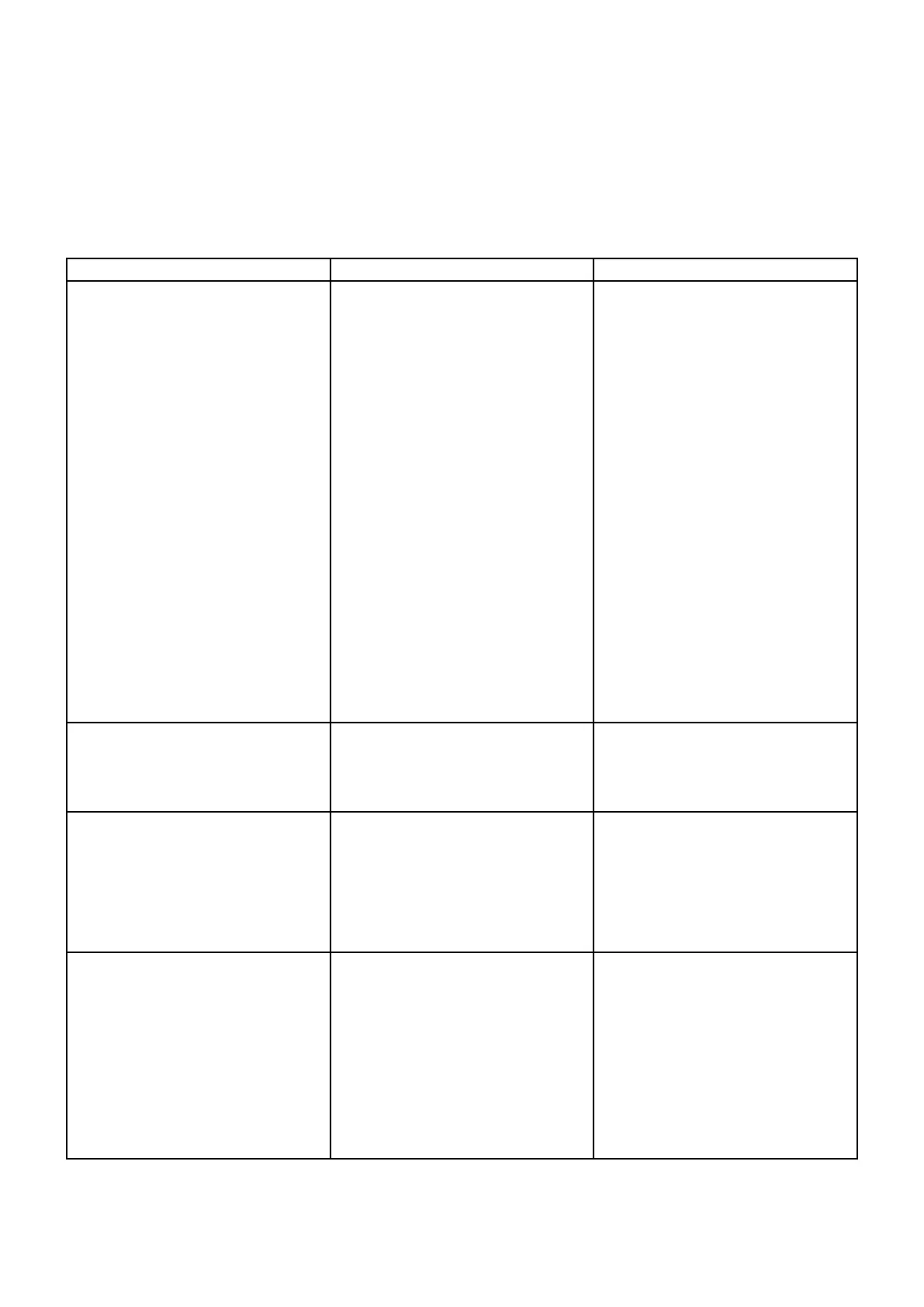

The troubleshooting table is divided into two catagories:

1. The results of the machine

2. Mechanical or electrical problems

1. PROBLEMS WITH RESULTS OF THE MACHINE

Problem Possible Cause Remedy

In- and out-feed marks. 1. Incorrectly adjusted in- and out-feed

tables.

2. The workpieces are not butted when

being fed into the machine.

3. The feeding pressure of the feed

rollers is incorrectly adjusted.

4. The workpiece is bent or warped.

5. There is play in the suspension of

the machine table.

1. Adjust the in- and out-feed tables

so that they are set to the same

height as the machine table. The

tables must also be in line with the

machine table or somewhat higher

at the outer ends. (see p.11).

2. Butt the workpieces end to end when

feeding them into the machine. This

will eliminate the variations of the

feeding pressure that can occur the

moment the feed rollers grab the

workpiece.

3. Make sure that the feeding pressure

is sufcient and that the rollers are

balancing horizontally over the

workpiece. (See p.21)

4. Slightly lift the back end of the

workpiece when it is being fed

into the machine. This will make

it possible for the feed rollers to

press the workpiece at against the

machine table.

5. By using little force, check if the

machine table can be wobbled in

any direction. If this is the case, read

Levelling the machine table (p.22).

The entire surface is fuzzy. 1. The workpiece has high moisture

content.

2. The knives have lost their

sharpness.

1. Dry the timber before machining it.

2. Grind the knives. It is especially

important that the knives are sharp

when soft or moist wood is being

machined.

Fuzzy surface around knots, where the

direction of the bres can vary.

1. The workpiece has high moisture

content.

2. The knives have lost their sharp-

ness.

3. The workpiece is of a too soft sort

of wood.

1. Dry the timber before machining it.

2. Grind the knives. DIt is especially

important that the knives are sharp

when soft or moist wood is being

machined.

3. Choose another material, or sand

the workpiece after it has been

machined.

The thickness of the board does not

correspond to the setting of the scale.

1. The takeoff of the knives in the upper

cutter are set incorrectly.

2. The pointer of the height scale is set

incorrectly.

1. Set the takeoff of the planing knives

to 1 mm, using Logosol’s setting

block (ref. no. 7500-000-1020) or

a magnetic adjuster for the upper

cutter (ref. no. 7500-001-0050).

2. Machine a test board, measure it and

set the pointer to this measurement.

Fine-tuning of measurements should

always be done using the rotating

scale of the height-adjusting crank,

which can easily be reset. The scale

shows 1 mm every quarter of a turn.

Loading...

Loading...