36

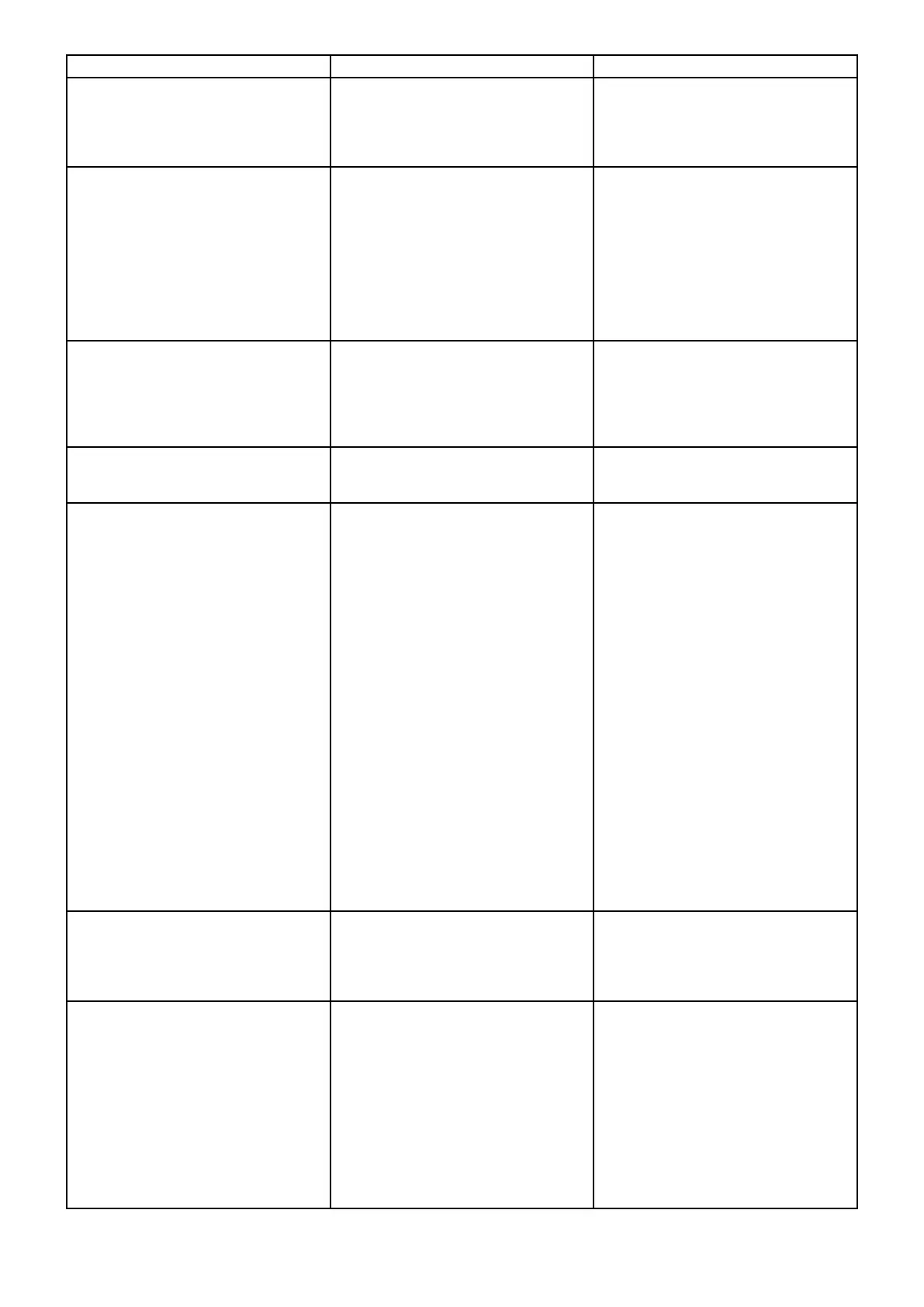

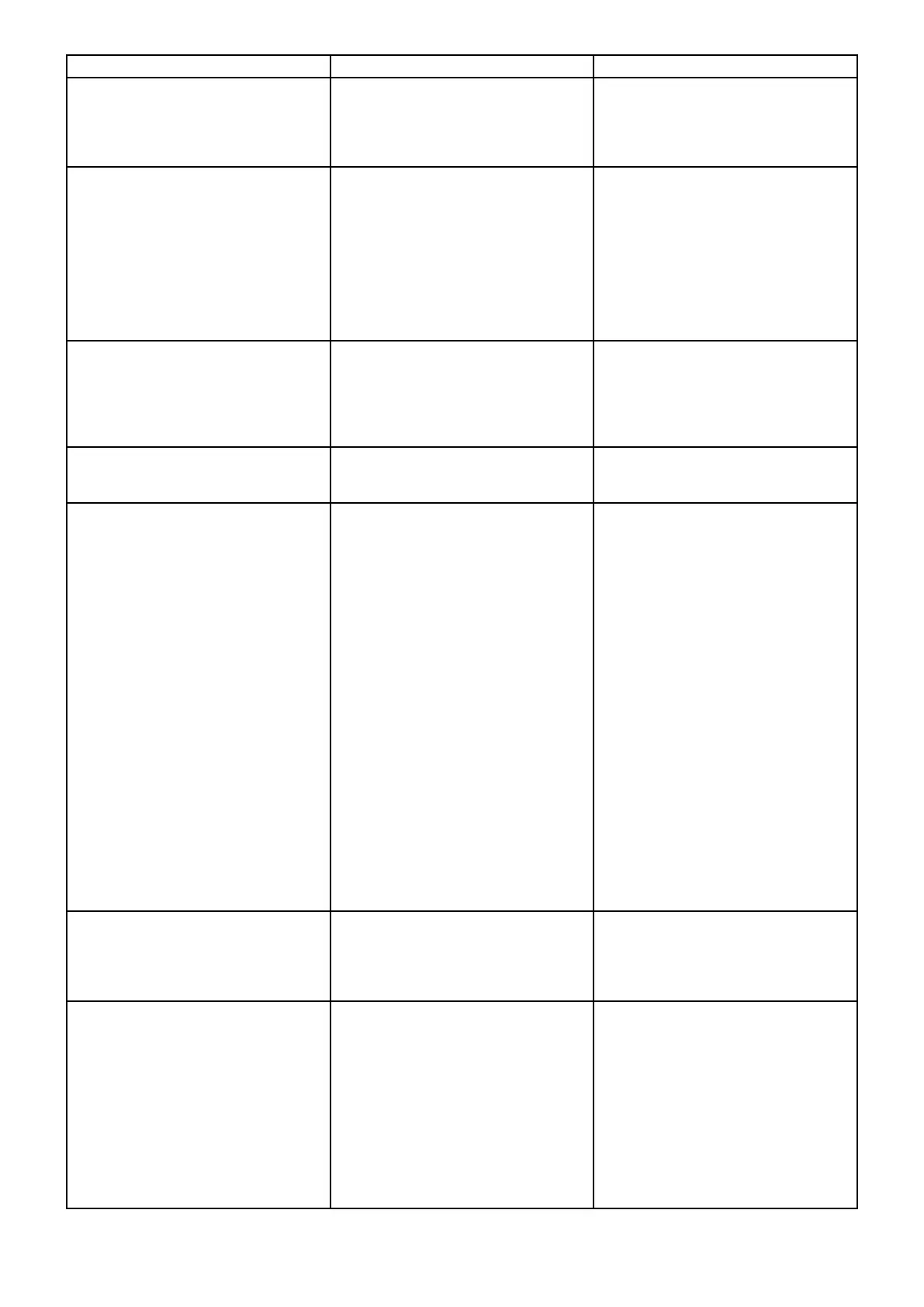

Problem Possible Cause Remedy

The upper cutter rotates a long time after

the machine has been shut off (the dece-

leration should be max. 10 seconds).

1. The fuse on the brake card has

blown.

2. The brake card is defect.

1. Replace the glass fuse on the card.

2. Replace the defect brake card.

On the new brake card there is a

potentiometer that has to be adjusted

(about 1/4 turn from 0).

One of the motors will not start. 1. Defect contactor.

2. Defect motor.

3. A cable to the contactor or to the mo-

tor is loose.

1. The electrical system may only be

opened by a qualied electrician:

Replace the defect contactor.

2. The electrical system may only be

opened by a qualied electrician:

Replace the defect motor.

3. The electrical system may only be

opened by a qualied electrician:

Ensure that all cables are correctly

connected.

The workpiece is fed jerkily through the

machine.

1. The machine table is covered with

resin or rust.

2. One of the feed rollers has been

bent.

1. Clean the table with Logosol’s

Machine Cleaner (ref. no.

7500-001-5000) and lubricate it with

Logosol’s Low Friction Agent (ref.

no. 7500-001-5050).

2. Replace the bent feed roller.

The machine runs for a while but then

stops.

1. One of the motors, in most cases

the motor of the upper cutter, gets

overheated.

1. See the point The motor gets

overheated.

The motor gets overheated. 1. Wood debris has accumulated in the

chassis of the machine or around

the cooling fans of the motors.

2. Dull knives.

3. Too low voltage in the power supply.

4. Loose or bad connection in the

power supply to the machine or in the

electrical system of the machine.

5. The upper cutter removes too much

wood.

6. The feeding speed is too high.

1. Make sure that wood debris has not

accumulated in the machine, and

that the cooling fans of the motors

have free ow. If the motors are

kept clean they will be cooled more

efciently.

2. Grind or replace the knives.

3. The electrical system may only be

opened by a qualied electrician:

Check that you have the correct

voltage on all phases.

4. The electrical system may only be

opened by a qualied electrician:

First of all, check that the connecting

cable has the correct current and

voltage during operation. Also check

that all wires are correctly connected

in the electrical system and motors

of the machine.

5. If the workpiece is to wide, of a hard

sort of wood or of varying oversizes:

plane it into size before the nal

machining.

6. Decrease the feeding speed.

Play in the adjusting crank of the mova-

ble side cutter.

1. The bronze bearing in the bearing

housing of the crank is defect. One

reason for this can be that the crank

has been turned when the locking

handle of the carriage is tightened.

1. Replace the bronze bearing and re-

member to open the locking handle

under the table before adjusting the

side cutter.

Vibration or rumble in the side cutter. 1. The moulding knives are incorrectly

mounted.

2. The moulding knives are incorrectly

ground.

3. Defect bearing.

4. The spindle shaft has been bent due

to overloading.

5. The belt transmission is defect.

1. Demount the cutter head, and clean

and mount the knives and the chip

breakers correctly. Identical knives

should be mounted on opposite

sides of the cutter.

2. Grind the knives in pairs so that they

are identical on the opposite sides of

the cutter.

3. Replace the bearing.

4. Replace the spindle shaft.

5. Clean the belt pulleys and replace

the Poly V belt.

Loading...

Loading...