Starting up

- 41 -

01.21 909.2669.9-02

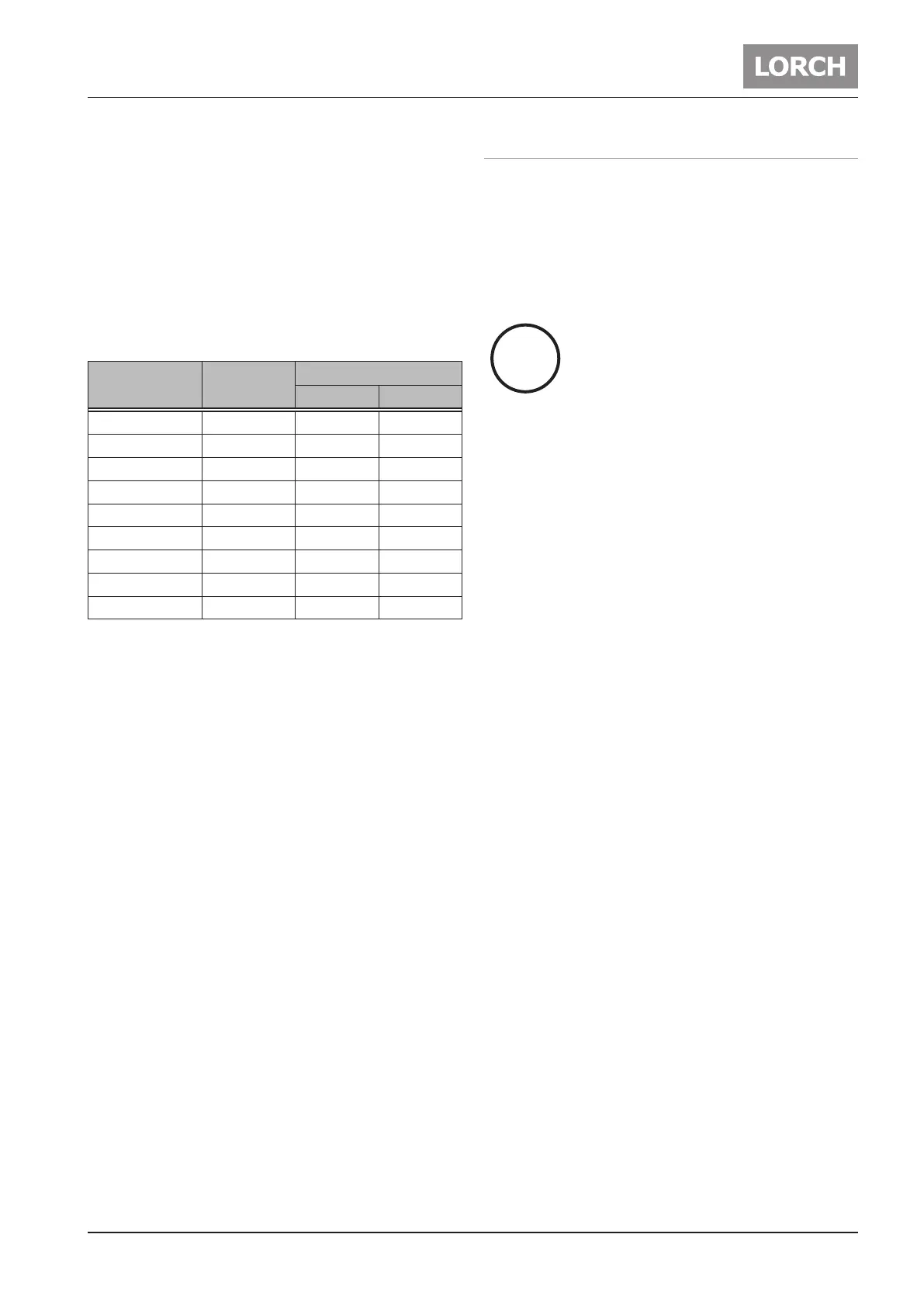

Adjustment of the torch-ID

Every torch of the i-LTG/i-LTW-series has an own torch-ID. This

ID is related to the stress limits of the torch. If the torch protec-

tion is activated (sub-parameter “tPr” = on) in the TIG-mode,

only a welding current according to the maximum torch limit

can be adjusted at the welding machine.

The adjustment of the torch –ID is necessary for e.g. if the

torch pc-board was changed.

Select in the user specic menu code-no. C00.

Adjust at the turning knob 41 the required torch-ID, ac-

cording to the torch-ID chart.

Type of torch Torch-ID

Stress limits

DC AC

i-LTG 900 9 125 A 80 A

i-LTG 1700 17 150 A 120 A

i-LTG 2600 26 200 A 160 A

i-LTG 2800 28 300 A 250 A

i-LTW 3000 30 320 A 220 A

i-LTW 1800 18 350 A 250 A

i-LTW 1800sc 19 400 A 320 A

i-LTW 2000 20 220 A 165 A

i-LTW 4500 45 450 A 360 A

Tab. 6: Torch-ID

For saving, press button on the right, main parameter 48.

9 The adjusted torch-ID is transferred to the torch.

14.6 Special functions

Gas test, control panel test

Press the mode switch on the top right 47 and the main

parameter switch on the bottom right 48 simultaneously.

The gas test is started for approx. 30 seconds. All LEDs and

the 7-segment display light up briey simultaneously.

If you press both switches again, the gas test ends.

Master reset

All welding and secondary parameters are re-

set to their factory settings (master reset func-

tion).

Press the button Welding Process 30 top left and hold

down.

Also briey press the button main parameters 48 bottom

right.

9 All LEDs and 7-segment displays light up briey.

9

i

Loading...

Loading...