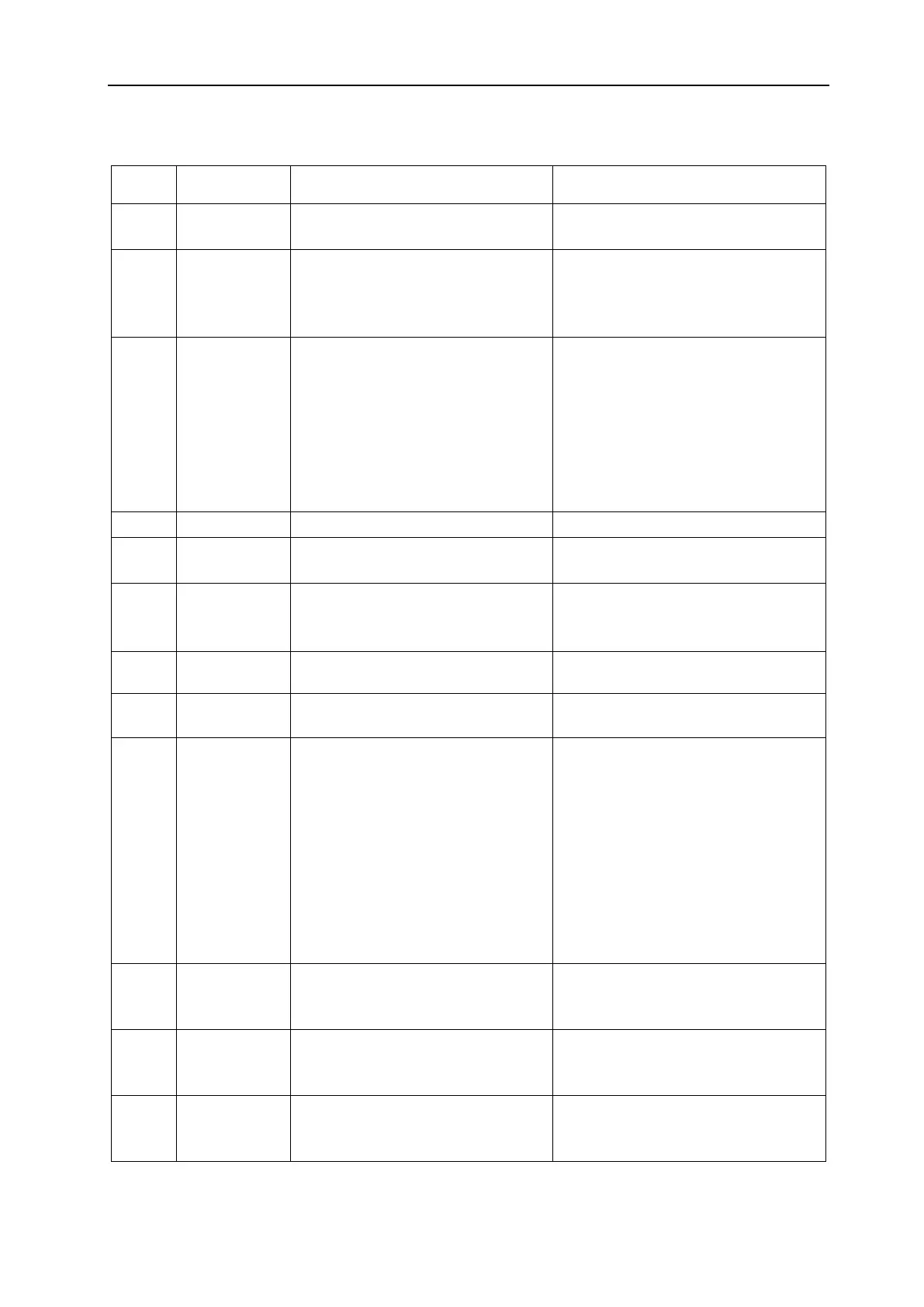

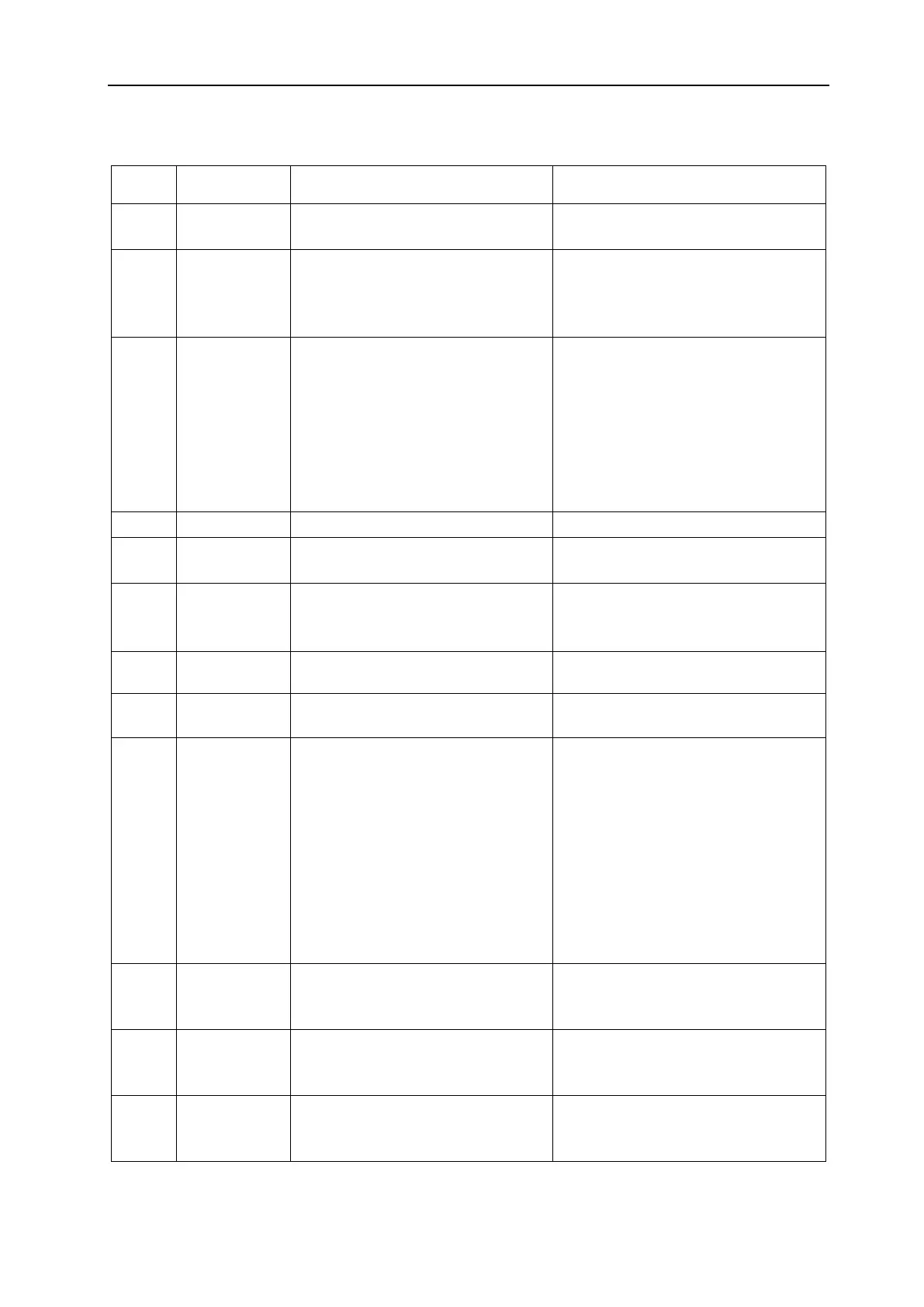

MAINTENANCE MANUAL OF ENGINE

141

9. Low power

Diesel filter or

fuel pump

The fuel inlet/outlet pipe or strainer

is blocked.

The fuel injector is damaged or

blocked, the fuel injector pressure is

inappropriate or the atomization is

poor.

Repair or replace (Refer to Section 6,

Chapter 3 of this Part)

The fuel injection pump does not

operate smoothly.

1. The plunger and barrel assembly of

the fuel injection pump is worn exces-

sively;

2. The governor spring is deformed or

loosened;

3. For abnormal operation of the fuel

injection pump, refer to Chapter 3 of

this Part to maintain the pump.

Ingression of air into the fuel system

Remove the air in the fuel pipeline.

Fuel supply

advance angle

The fuel supply advance angle is

insufficient.

Adjust the fuel supply advance angle

to 16°±1°

The fuel delivery error of cylinders is

out of specification.

Adjust the delivery unevenness of cyl-

inders to specified range: Nominal:

10%; Calibrated: 10%; Idling: 30%.

The air intake is not smooth.

Clean or replace the filter element

The intake and exhaust valve clear-

ance is inappropriate.

Adjust (Refer to Section 1, Chapter 3

of this Part)

The valve mechanism parts are worn

seriously.

Change the worn parts as required, and

adjust the valve timing:

Intake valve open Before upper dead

point 12±3°

Intake valve closed After lower dead

point 38±3°

Exhaust valve open Before lower dead

point 50±3°

Exhaust valve closed After upper dead

point 14±3°

There is air leakage from the sealing

surface between the seat and cylinder

head.

Remove the carbon deposit or tighten

the set bolts.

Cylinder head

Cylinder head

gasket

The cylinder head bolts are loosened;

There is air leakage from the cylin-

der head gasket.

The tightening torque for the cylinder

head bolts is (145~155)N.m;

Change the cylinder head gasket.

The piston ring is deposited with

carbon, jammed or worn.

Clean the carbon deposit or replace it

with new one (Refer to Section 4,

Chapter 2, Part II)

Loading...

Loading...