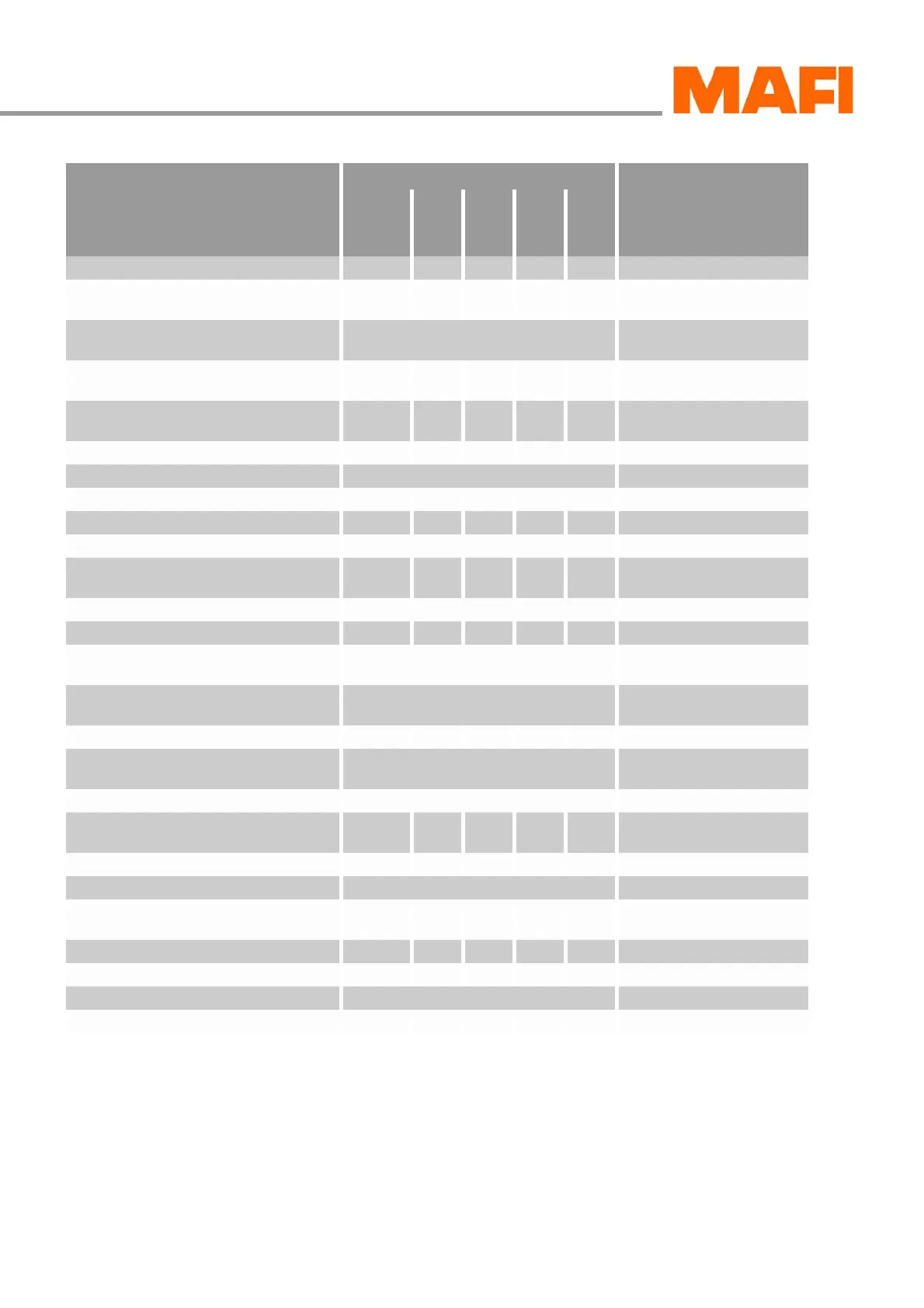

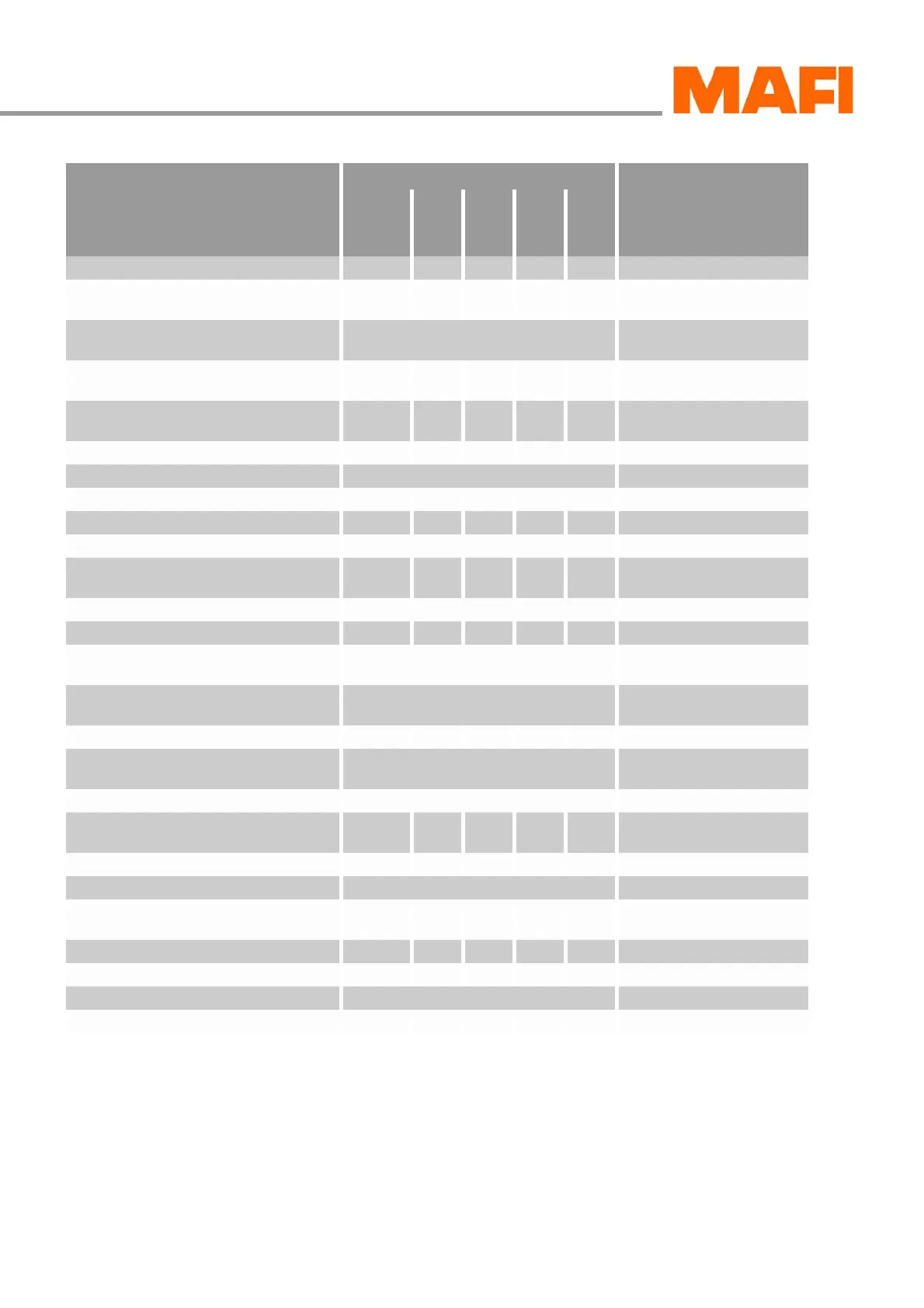

MAINTENANCE WORK

MAINTENANCE SCHEDULE

36 Maintenance manual T225/T230

Brakes

Check the brake lining thickness and

flexibility of the brake shoes

X X X X Manufacturer's operating

manual

Set the initial position of the brake shoes after replacing the brake linings Manufacturer's operating

manual

Check the setting and function of the brake

rods adjuster

X X X Manufacturer's operating

manual

Lubricate brake shaft bearing (FA) X X X X X Manufacturer's operating

manual

Hydraulics

Check oil level Daily page 82

Change hydraulic oil

2)

X X page 84

Change oil filter

2)

X X page 84

Check oil level hand pump driver's cab Monthly page 86

Check hydraulic hoses and connections

for damages and tight fit

X X X X X page 87

Replace hydraulic hoses Every five years at the latest page 87

Fifth wheel / fifth wheel coupling

Check for wear Monthly Manufacturer's operating

manual

Lubricate grease pockets, locking

mechanism, and bearing

Weekly page 38

Wheels / Tyres

Check tyre pressure and the tyres for

damage

Daily page 91

Check wheel rims for damage Weekly page 91

Check wheel bolts and nuts for damage

and firm fit

X X X X X page 91

Vehicle battery

Check acid level Weekly page 97

Check battery charge status / charge

battery

X X X X X page 97

Check battery poles and connections X X X X X page 97

Electrical system

Check lighting system Daily page 98

Check fuses X X X X page 99

1)After every 2000 operating hours, the maintenance tasks are repeated, starting at 500 operating hours.

2)Carry out the maintenance work at least once a year.

3) When using synthetic transmission oil, extend the oil change interval to 2000 operating hours or perform the oil

change at least every two years.

Maintenance task Operating hours

1)

Description found in

initially

after

50–100

500 1000 1500 2000

Loading...

Loading...