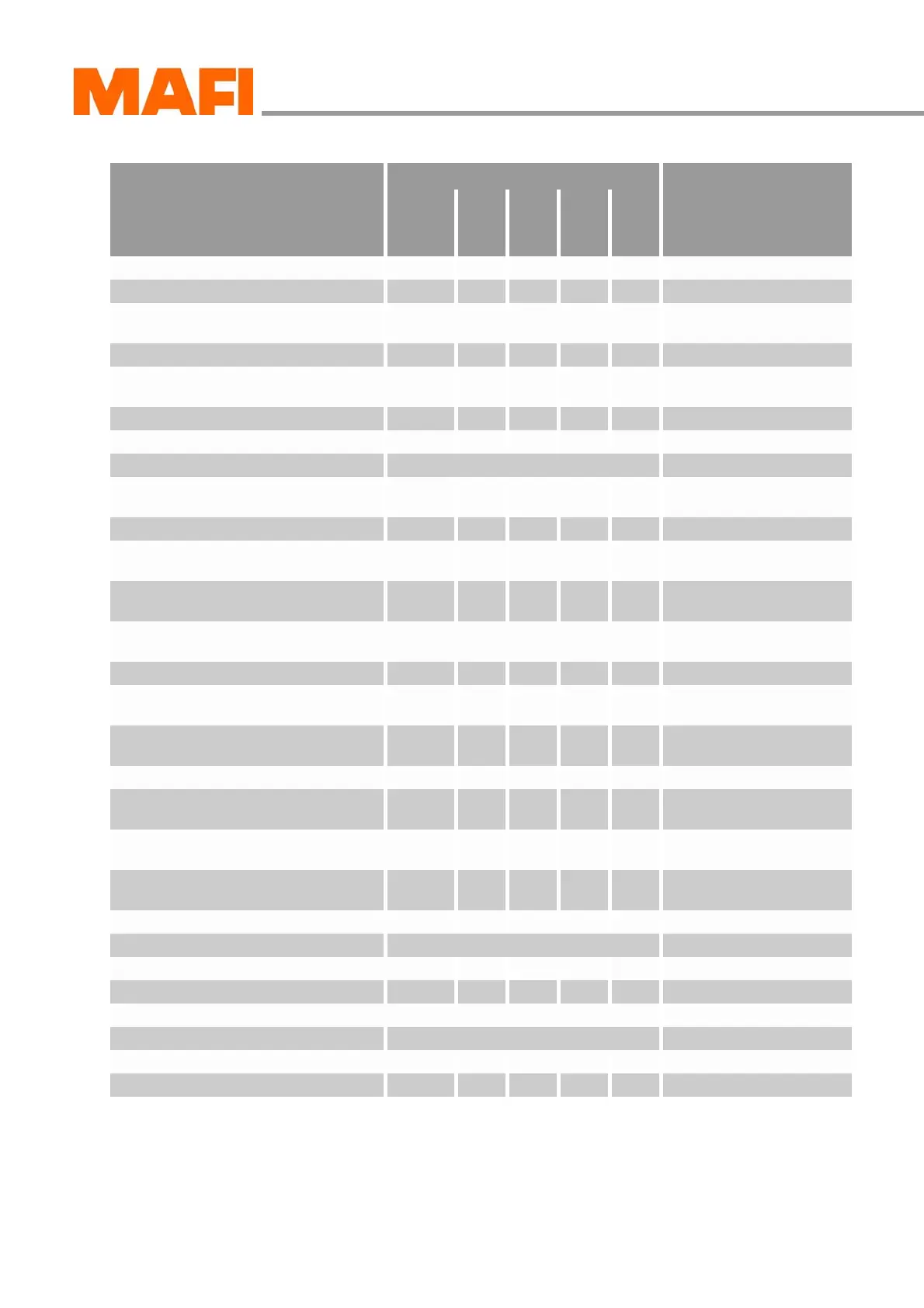

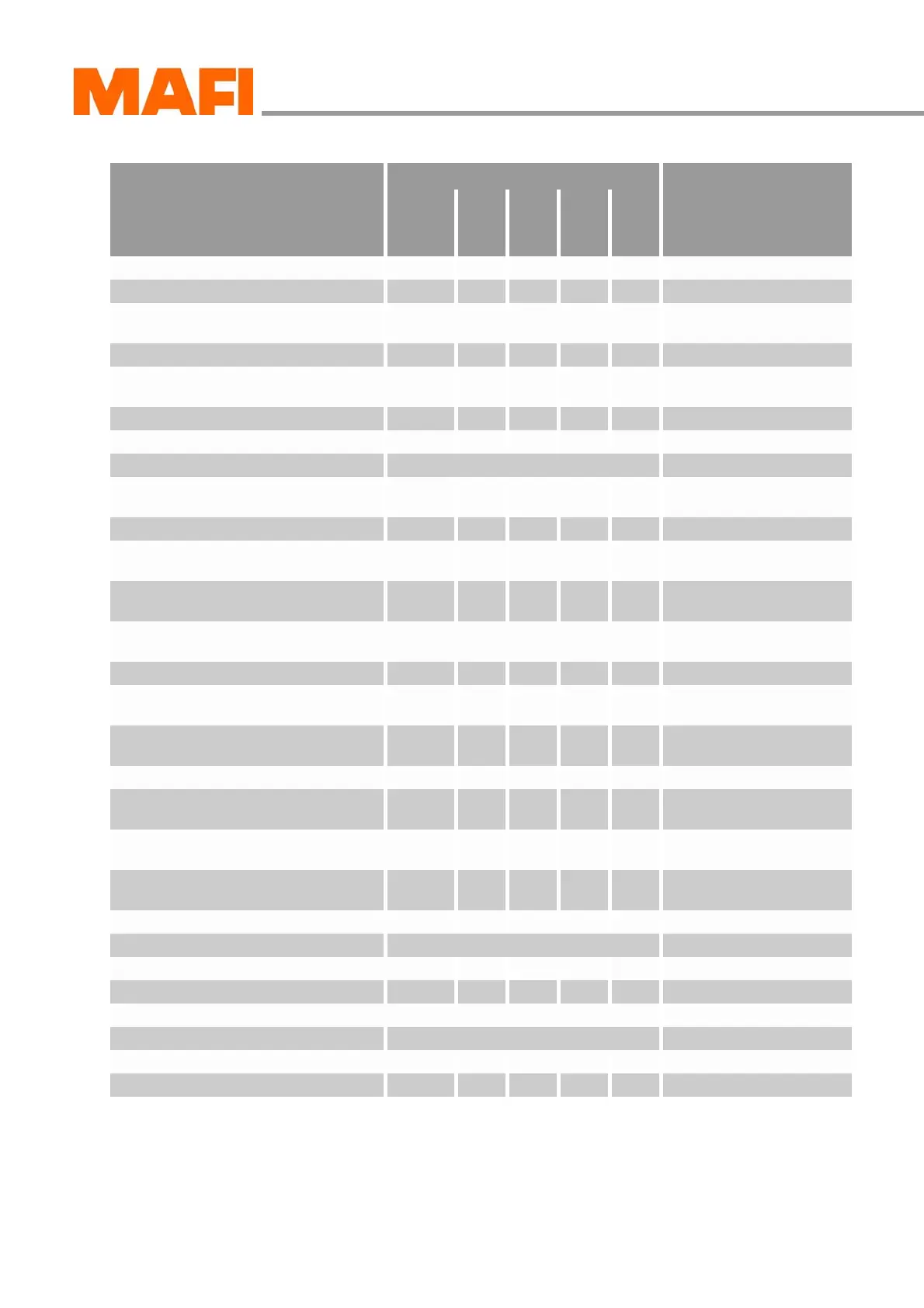

MAINTENANCE WORK

MAINTENANCE SCHEDULE

Maintenance manual T225/T230 35

Fuel system

Empty fuel tank

2)

X X page 65

Check fuel pre-filter and dewater if

necessary

Monthly page 63

Replace fuel pre-filter element X X X X X

Replace fuel filter X X X X Manufacturer's operating

manual

Check fuel lines for leaks X X X X page 62

Transmission

Check transmission oil level Daily page 67

Change oil and oil filter

2) 3)

X X X X X Manufacturer's operating

manual

Axle differential (RA)

Check oil level X X X X X Manufacturer's operating

manual

Change oil (X) X X Manufacturer's operating

manual

Check venting with every oil change Manufacturer's operating

manual

Planetary gears in the wheel hub (RA)

Check oil level X X X X X Manufacturer's operating

manual

Change oil

2)

(X) X X Manufacturer's operating

manual

Front axle

Check and adjust wheel hub bearing play X X Manufacturer's operating

manual

Check and adjust steering knuckle pin play X X X Manufacturer's operating

manual

Lubricate bottom steering knuckle

connection

X X X X X Manufacturer's operating

manual

Compressed air system

Check compressor Monthly page 77

Check / replace compressed air line X page 78

Check / replace intake line X page 77

Check compressed air tank Weekly page 78

Dewater compressed air tank Weekly page 80

Replace air dryer cartridge

2)

X page 81

1)After every 2000 operating hours, the maintenance tasks are repeated, starting at 500 operating hours.

2)Carry out the maintenance work at least once a year.

3)When using synthetic transmission oil, extend the oil change interval to 2000 operating hours or perform the oil

change at least every two years.

Maintenance task Operating hours

1)

Description found in

initially

after

50–100

500 1000 1500 2000

Loading...

Loading...