Quattro DC User Switches C1 Submenu

75

Ramp Stop Select

This parameter allows the selection of the

Torque Ramp Down Stop function. This

function is used to gradually remove the torque

command after the elevator has stopped and

the mechanical brake has been set. This

prevents a shock and possible ‘bump’ felt in

the elevator from the torque signal going to

zero too quickly.

A function unique to elevators involves the

interaction between the motor torque and the

mechanical brake that holds the elevator.

Under full load conditions at the end of a run, if

the brake is set and the motor torque is

removed quickly, some brake slippage may

occur. Therefore, the option of gradually

reducing the motor torque is provided by the

Torque Ramp Down Stop function.

Upon being enabled by the Ramped Stop

Select Parameter (RAMPED STOP SEL(C1)),

the torque command is linearly ramped to zero

from the value that was present when the

‘Ramp Down Enable’ was selected.

The Ramp Down Enable has the following

three possible sources:

An input logic bit (EXTERNAL TB)

The run logic – initiated by the removal of

the run command

The serial channel

The Ramp Down Enable Source parameter

(RAMP DOWN EN SRC(C1)) is used to select

one of the above options.

A method of providing the Ramp Down Enable

would be with a logic signal (EXTERNAL TB)

that is dedicated to that function. The Ramp

Down Enable would be asserted while the Run

command is still present and remain there until

the ramp is completed, after which the Run

command would be removed.

The RUN LOGIC option to trigger the Ramp

Down Enable from the Run command is

provided. In this case, removal of the Run

command enables the Ramp Down Stop

Function.

The time it takes for the Drive to perform its

ramped stop is determined by the Ramped

Stop Time Parameter. The Ramped Stop

Time parameter (RAMPED STOP TIME(A1))

selects the amount of time it would take for the

drive to ramp from the rated torque to zero

torque.

NTSD MODE

(Normal Terminal Stopping Device Mode)

This parameter allows the drive to perform

preprogrammed NTS slowdown. The drive will

ignore most speed command (drive will follow

any speed command slower than the NTSD

Target Speed to ensure proper floor leveling) it

is being told to run at, slow down using the

SCurve 4 parameters, and clamp the drive

speed command at NTSD Target Spd (A1) if it

measures an elevator speed faster than what

is set in NTSD Threshold 1 (A1), NTSD

Threshold 2 (A1), and/or NTSD Threshold 3

(A1) to when the logic input NTSD Input 1 (C2)

and/or NTSD Input 2 (C2) isn’t being triggered.

There are 4 methods that can be selected:

External: This should be selected if the drive

NTSD function will not be used or if it is

desired for the drive to go into NTSD mode as

soon as NTSD Input 1 (C2) is triggered logic

low. The drive will immediately slow down

using SCurve 4 to the NTSD Target Spd (A1)

and clamp the speed there. The drive will get

out of NTSD mode and back into normal

operation when: the NTSD input is re-asserted

as logic high again.

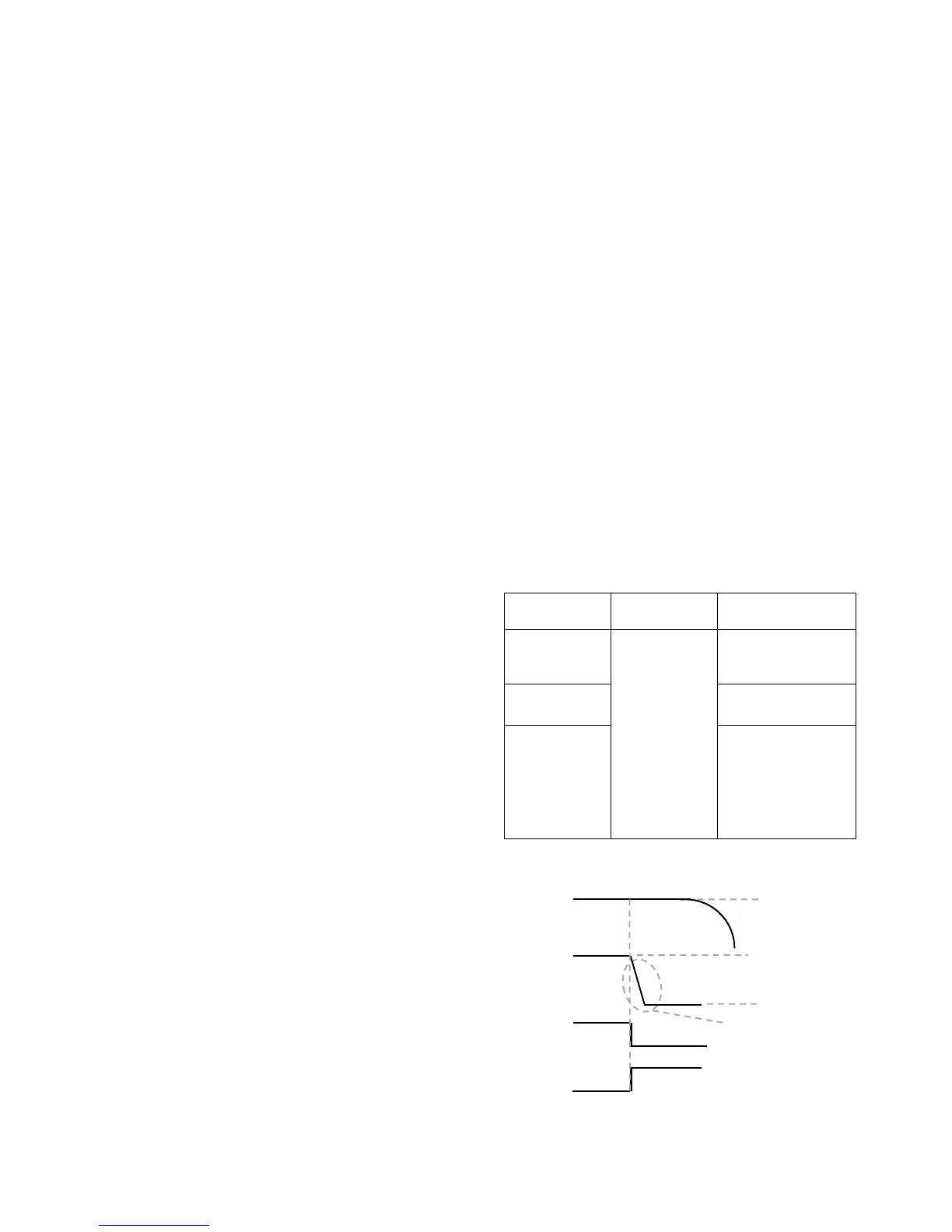

NTSD Input

1

NTSD Input

2

Result

Not Used

Not Used

Internal NTSD

function of drive

is not used

1

Normal

Operation

0

Use S-Curve 4 to

decel and run at

NTSD Target

Speed, OR run at a

slower supplied

drive speed

command

Table 9: External NTSD Mode function table

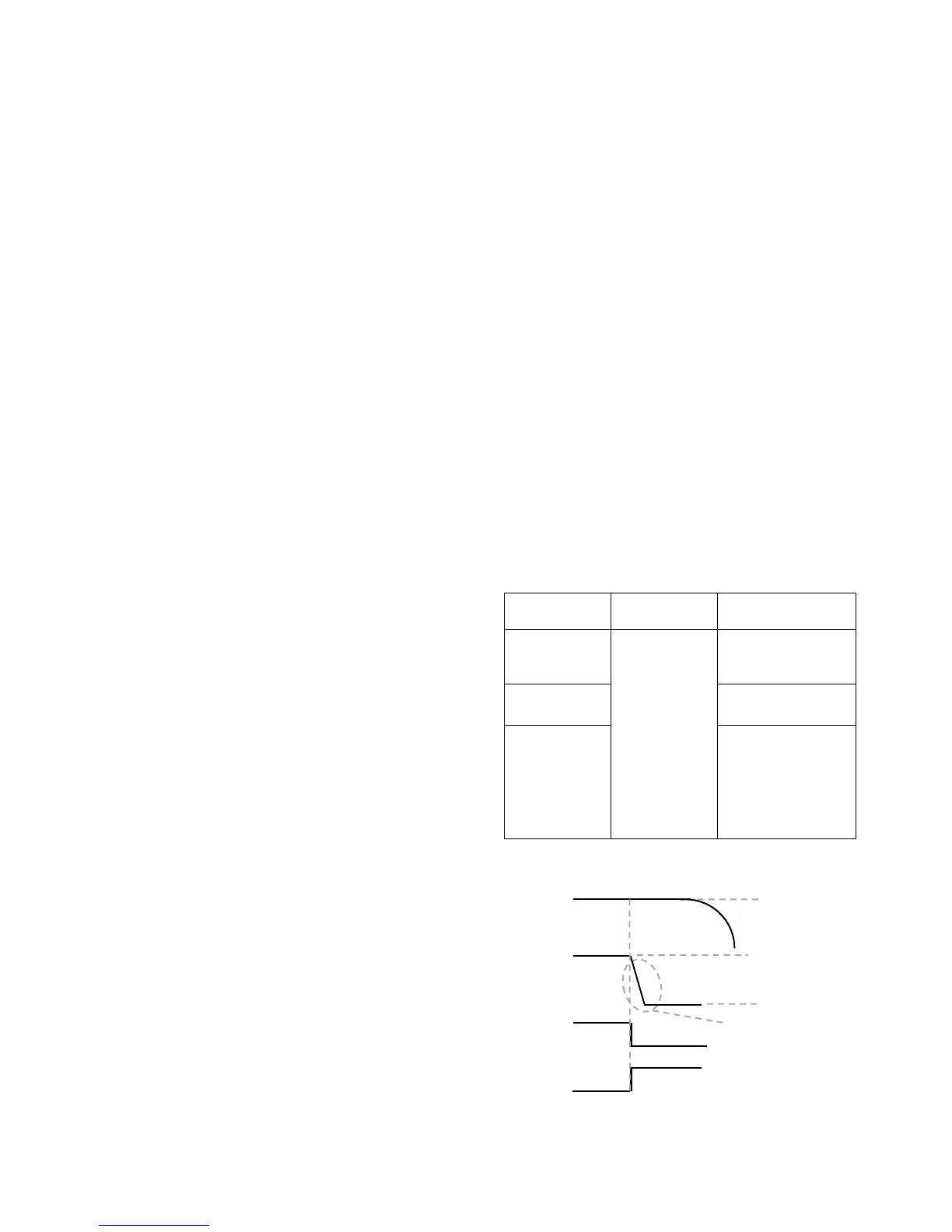

Figure 17: External NTSD Mode

Decel rate 4 (A2)

Decel jerk in/out 4

NTSD Active

(C3)

NTSD Input 1

(C2)

70fp

70fp

NTSD Target

Spd (A1)

Elevator

S

eed

Controlle

r

Loading...

Loading...