6

-4

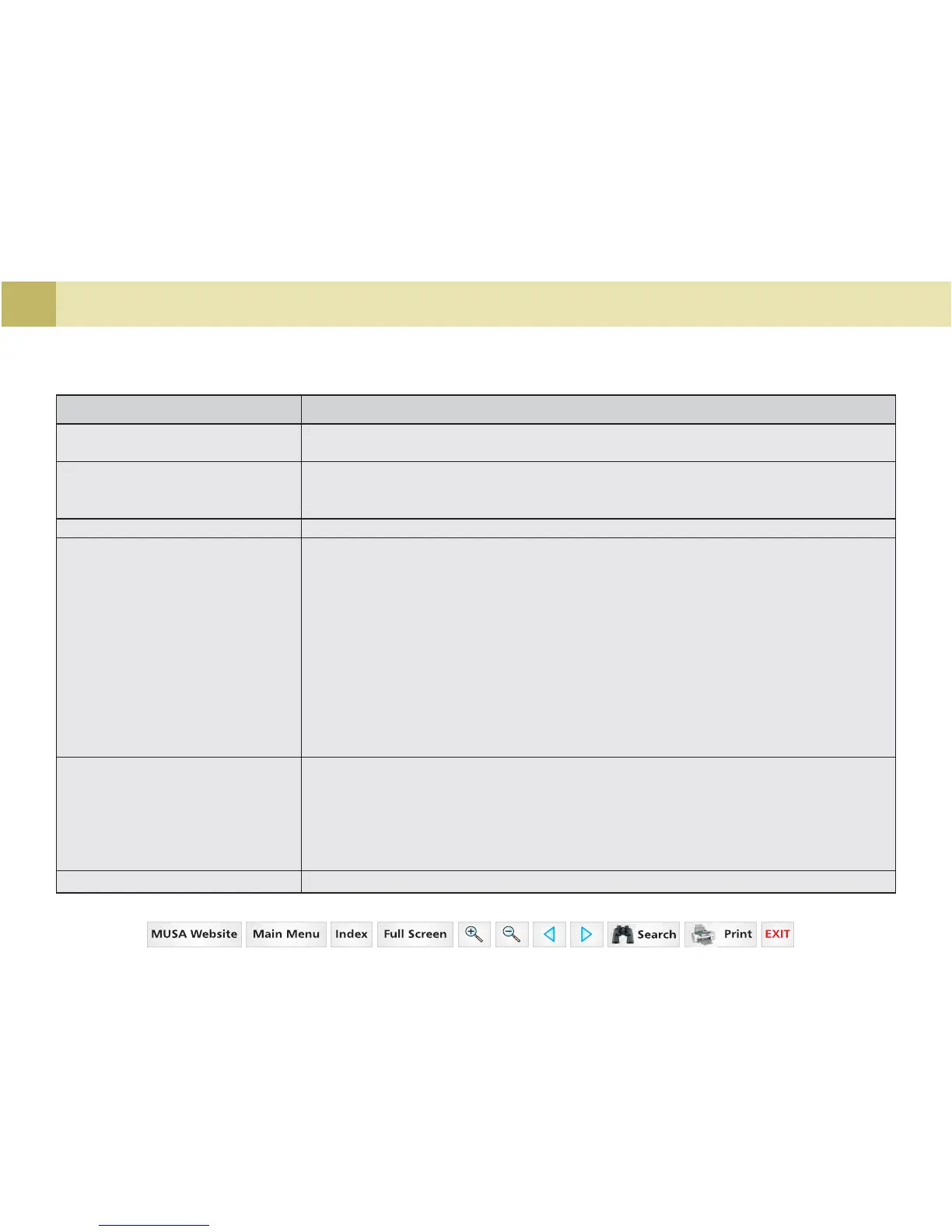

DIESEL ENGINE

ENGINE LACKS POWER

Possible causes Actions

Carbon deposit at injection nozzle

inlet

•

Clean the inlet and needle valve carefully not to damage the nozzle inlet.

•

Check the nozzle. Replace with a new nozzle if necessary.

Leaks from valve due to low com-

pression

•

Defective valve or excessively worn ring, piston, and liner will result in low compression.

Replace it with a new one.

•

Polish the valve.

Lack of the fuel

•

Check the feul system.

Moving parts overheating

•

Check the lubrication system.

•

Check if the oil fi lter is working properly.

•

Filter screen or element with debris will degrade the lubricant cleaning screen.

Replace the element.

•

Check the injection timing

•

Proper injection timing (crank angle before top dead center)

BTDC 18˚- 3C093LWS/3C100LWS/3A139LWS/3A150LWS/3A150LWG/

3A165LWS/3B183LWS/4A200LWS/4A220LWS/4A220LWG

BTDC 24˚- 3C093LWG

BTDC 22˚(CTD, main) - 4B243LWS

BTDC 12˚(sub port) - 4A200TLWS/4A220TLWS

In correct valve adjustment

•

Check and adjust valve clearance when the engine is cold.

Intake ; 0.15mm Exhaust ; 0.15mm - 3C093LWS/3C093LWG/3C100LWS

Intake ; 0.25mm Exhaust ; 0.30mm - 3A139LWS/3A150LWS/3A150LWG/3A165LWS/

3B183LWS/4A200LWS/4A220LWS/4A220LWG/

4B243LWS

Intake ; 0.20mm Exhaust ; 0.20mm - 4A200TLWS/4A220TLWS

Air cleaner contamination

•

Clean or replace the element every 100hours of operation.

Loading...

Loading...