E3 – CONDITION OF THE CYLINDERS (LEAKS, RODS)

CHECK

Check the condition of the cylinders. There must be no:

• Hydraulic leaks from the seals and the valve blocks

• Impacts on the cylinder rods

E - EVERY 1000 HOURS OF OPERATION

Perform the operations described above as well as the following operations.

E1 – FUEL TANK

DRAIN / CLEAN

t

IMPORTANT

t

Never smoke or approach the machine with a naked flame during this operation.

Set the lifting platform on a horizontal surface with the engine off.

- Check visually and by touch the parts likely to have leaks in the fuel circuit and

the tank.

- In the even of a leak, contact your dealer.

t

IMPORTANT

t

Never attempt to make a weld or any other operation by yourself; this could cause an explosion or a fire.

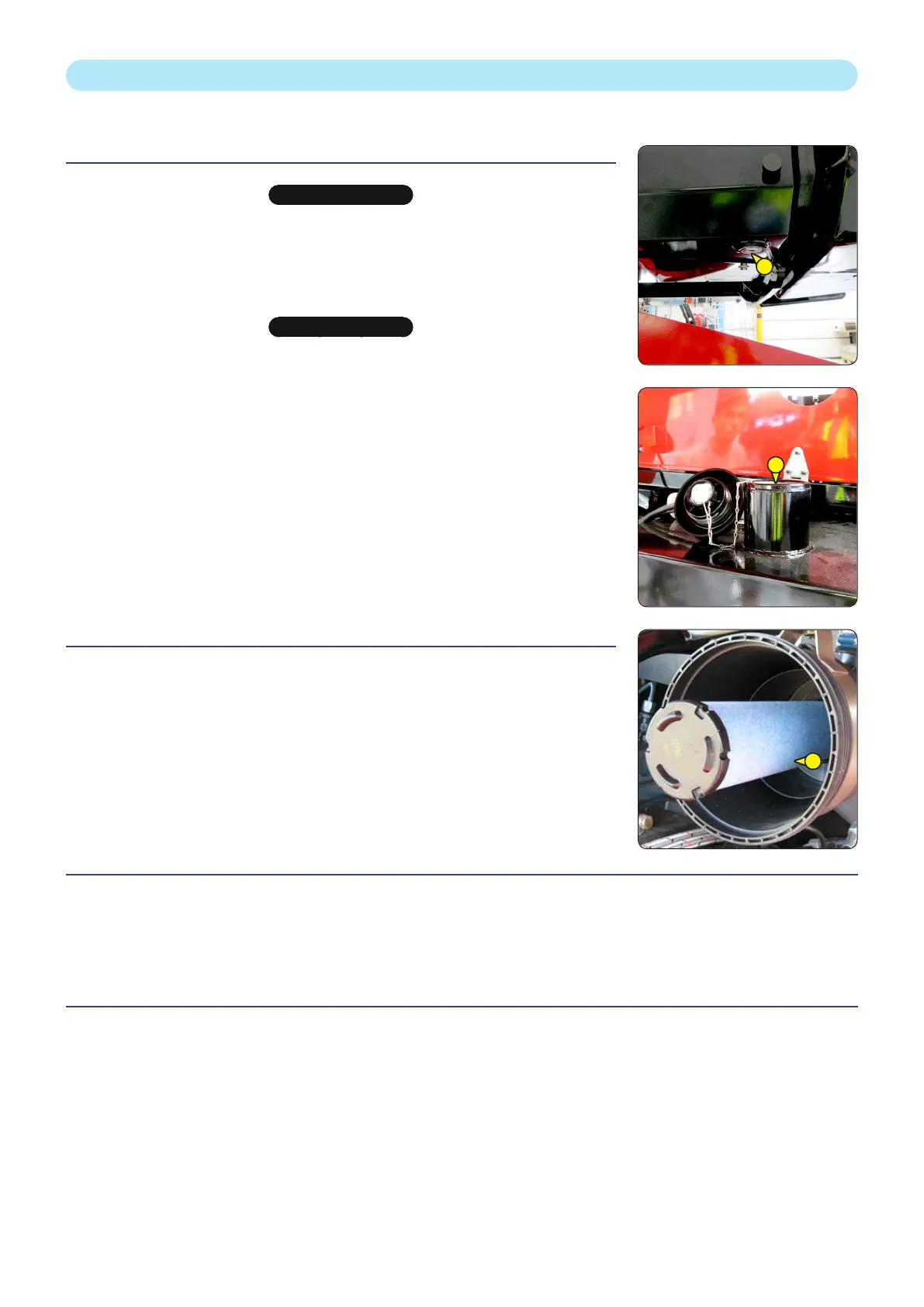

- Set a receptacle under the drain plug 1 and loosen the drain plug.

- Let the diesel flow out and rinse out with ten litres of diesel poured through the

filling hole 2.

- Refit and tighten the filling cap 1.

- Refill the fuel tank with clean diesel filtered through a strainer or a clean lint-free

cloth and refit the filling cap.

E2 – DRY AIR FILTER SAFETY CARTRIDGE

REPLACE

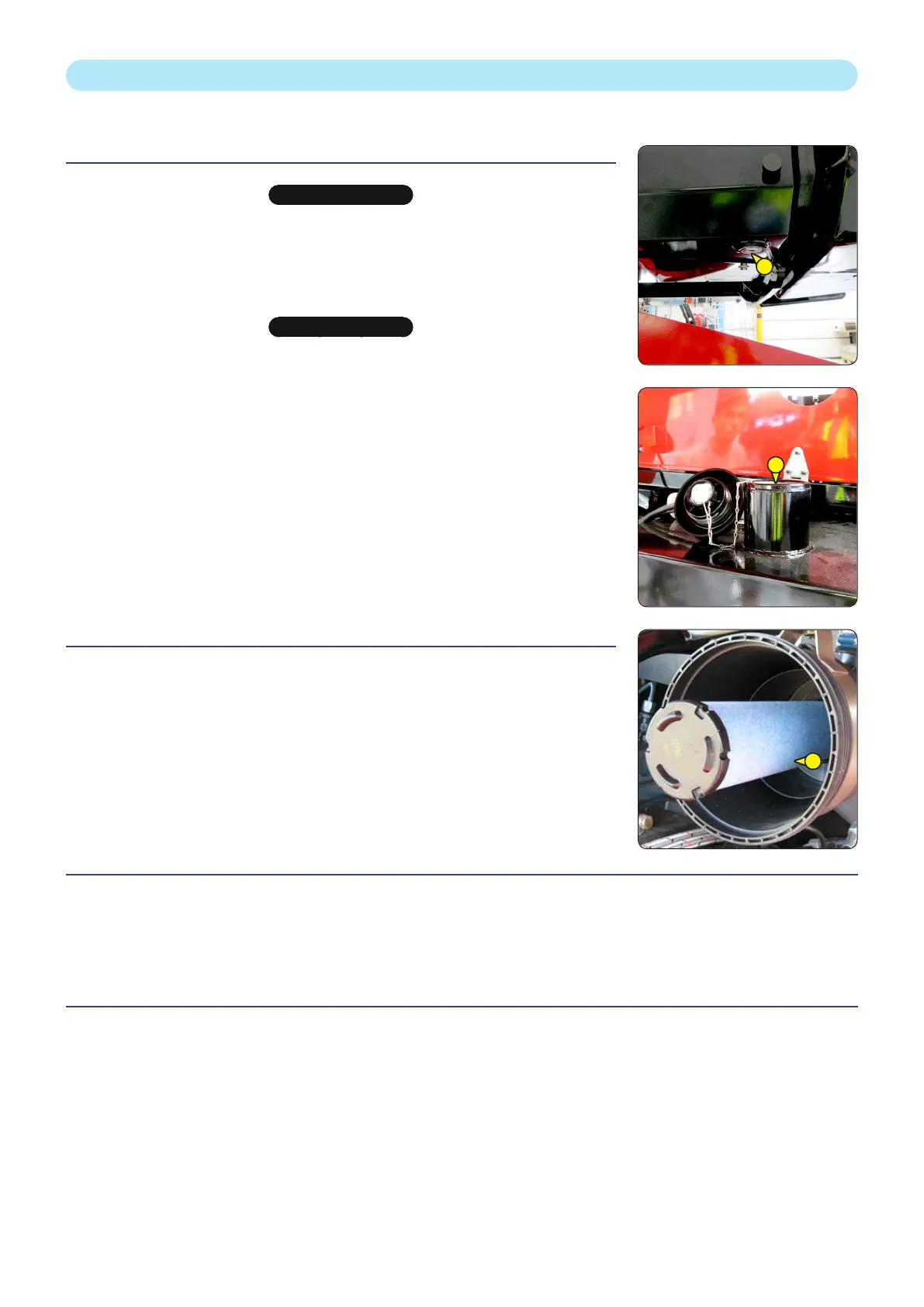

- Open the chassis right cover.

- Remove the dry air filter cartridge 1 (See § D1).

- Remove the dry air filter safety cartridge 2 and replace it with a new one.

- Refit the assembly (see § D1).

E4 – CONDITION OF THE CABLE BUNDLES AND THE CABLES THEMSELVES

CHECK

Inspect the following sectors, check the condition of the bundles: no deterioration and nothing loose.

• Base control console,

• Hydraulic block,

• Battery,

• Intermediate joint,

• Basket control console.

3 - 30

2

1

1

647533 (09/10/2015)

MAN'GO 12

Loading...

Loading...