G - OCCASIONAL MAINTENANCE

G1 – FUEL SUPPLY SYSTEM

BLEEDING

This series of operations should be performed only in the following case:

• A component in the supply circuit needs to be replaced or drained.

• The fuel tank is empty.

• Before the engine is used after a long period of inactivity.

- Ensure that there is sufficient fuel in the tank and turn the ignition key to the second

notch to switch the machine on.

- Open the chassis left cover.

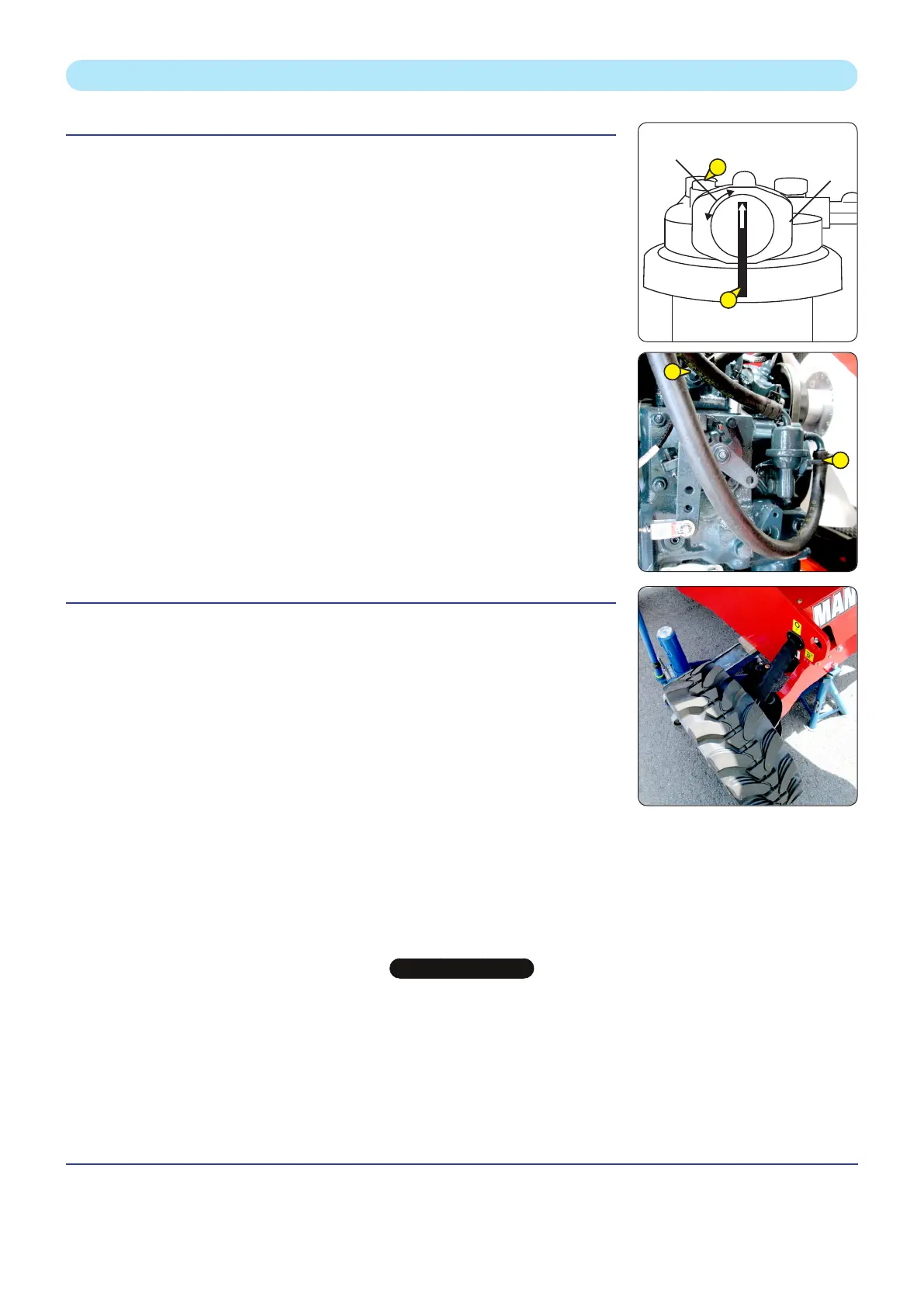

BLEEDING THE FUEL FILTER

- Refill the tank.

- Open the fuel filter tap 1.

- Slightly loosen the fuel filter vent plug 2.

- Use the lever 3 to operate the feed pump manually.

- Retighten the plug when no more bubbles form.

- Open the vent plug in the top of the injection pump 3.

- Use the lever 3 to operate the feed pump manually.

- Retighten the plug when no more bubbles form.

G2 – WHEEL

CHANGE

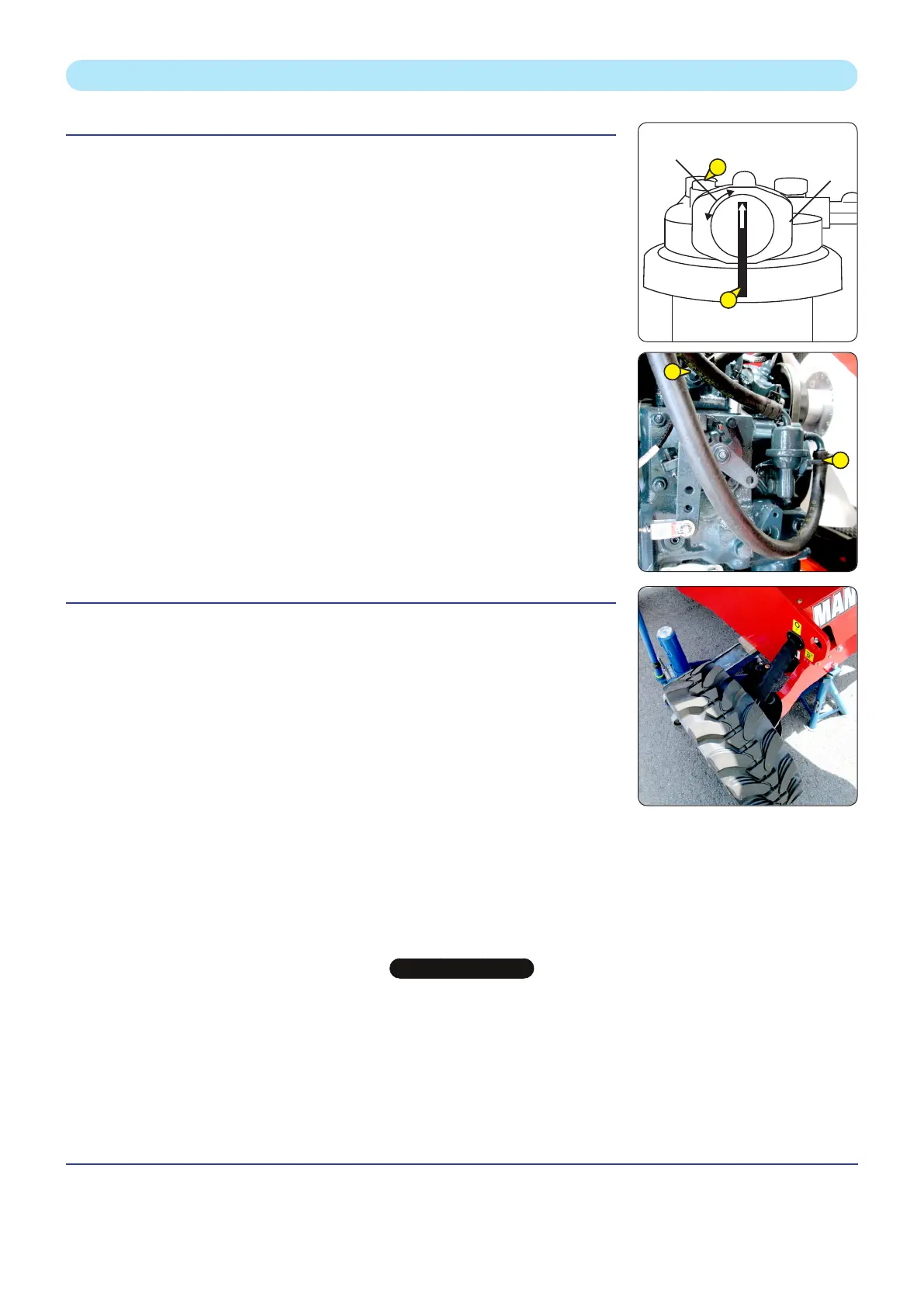

- Stop the lifting platform on a firm, horizontal surface if possible.

- Proceed to switch off the machine (see: 1 – SAFETY INSTRUCTIONS AND ADVICE:

DRIVING INSTRUCTIONS WHILE UNLADEN AND LOADED).

- Chock the lifting platform in both directions on the axle opposite the wheel to be

changed.

Reminder :

Load on one wheel : 2700 kg

Recommandations :

For using the MANITOU hydraulic jack Ref. 505507 and the MANITOU safety stay Ref.

554772:

- You are recommended to replace the rear wheels then, after turning the turret half a turn, to replace the front wheels.

This operation enables you to distribute the load on the axles by positioning the counterweight on the axle opposite

the wheel change.

- Unlock the nuts on the wheel to be changed.

- Set a jack under the axle housing as close as possible to the wheel and adjust the jack.

- Raise the wheel until it is slightly off the ground and place the safety stay under the axle.

t

IMPORTANT

t

The weight of one wheel is 96 kg.

- Release the wheel by to and fro movements.

- Slip the new wheel over the hub.

- Screw on the nuts by hand, greasing them, if necessary.

- Remove the safety stay and lower the lifting platform with the jack.

- Tighten the wheel nuts with a torque wrench (see: 3 - MAINTENANCE: B - EVERY 250 HOURS OF OPERATION for the

tightening torque).

G3 – LIFTING PLATFORM ON A TRUCK BED

TRANSPORT

See Section 2: LOADING / UNLOADING THE LIFTING PLATFORM

3 - 34

1

4

3

2

647533 (09/10/2015)

MAN'GO 12

Loading...

Loading...