B - EVERY 50 HOURS OF OPERATION

Perform the operations described above as well as the following operations.

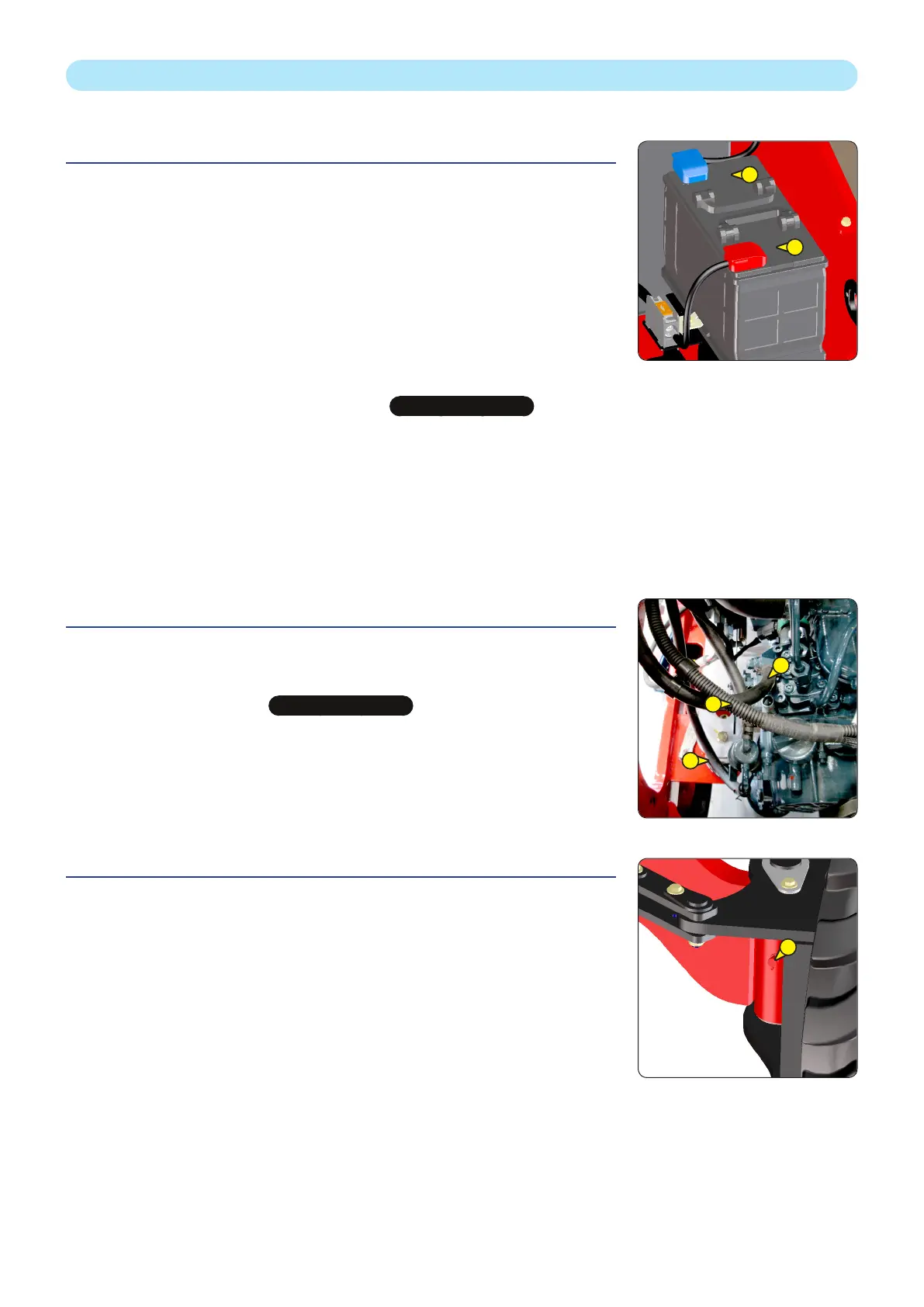

B1 – LEVEL OF BATTERY ELECTROLYTE

CHECK

Check the electrolyte level in each battery.

If the ambient temperature is high, check the level more often than every 50 hours of

operation.

- Release the caps over the elements 2.

- The level should be 1cm above the battery plates.

- If necessary, top up with distilled water, kept in a glass container.

- Clean and dry the caps 2 (Fig. B1/2) and refit them.

- Check the terminals and apply Vaseline to prevent them from oxidizing.

t

IMPORTANT

t

Manipulating and servicing a battery can be dangerous; take the following precautions:

Wear protective goggles.

Keep the battery horizontal when manipulating it.

Never smoke or work close to a naked flame.

Work in a sufficiently well-ventilated area.

If some electrolyte splashes onto your skin or in your eyes, rinse the affected area thoroughly with cold water for 15 minutes and call a doctor.

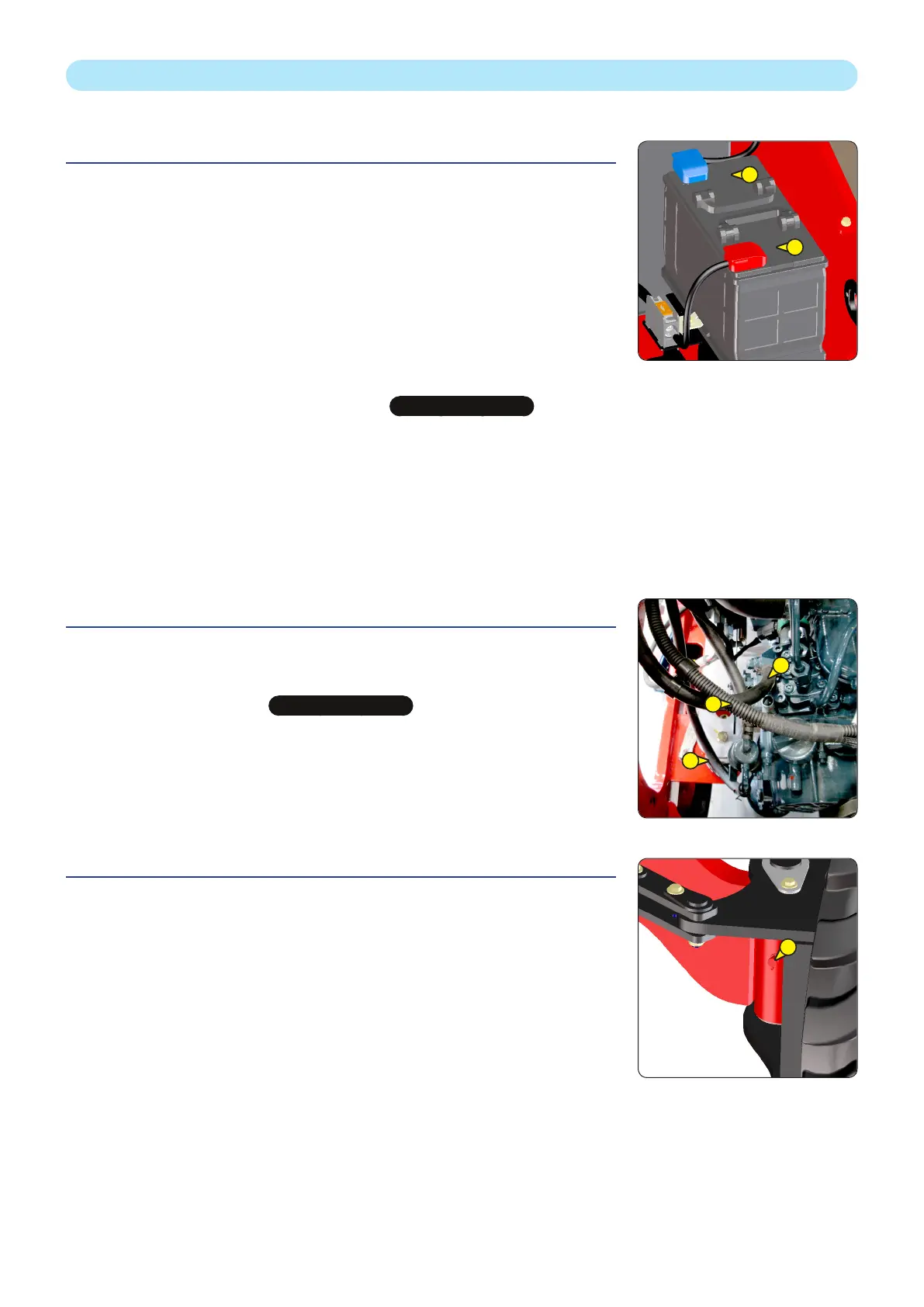

B2 – FUEL CIRCUIT HOSE

CHECK

Set the lifting platform on a horizontal surface, with the engine switched off, and wait

for the engine to cool down.

t

IMPORTANT

t

Check the condition of the fuel circuit hoses after switching off the engine. If the fuel supply hoses are damaged, this

can cause a fire.

- Open the rear cover. Open the engine support to facilitate access to the engine.

- Visually inspect the condition of the fuel circuit’s supply hoses 1, 2 ,3 and the

tightening collars. If these are damaged, replace them immediately.

B3 – DIRECTION PIVOTS

GREASE

Clean and grease (see: 3 - MAINTENANCE: FILTER ELEMENTS AND BELTS) and remove

the excess.

Make the same operation on the second pivot.

3 - 14

2

1

3

2

2

3

647533 (09/10/2015)

MAN'GO 12

Loading...

Loading...