REPLACE Coolant

These operations are to be carried out as necessary or every two years at the beginning

of winter.

IMPORTANT

The engine does not contain any anti-corrosion element and must be filled with a mixture containing25% of ethylene

glycol-based antifreeze all year round.

- Place the lift truck on level ground with the engine stopped and cold.

- Open the engine cover (2-DESCRIPTION-INSTRUMENTS AND CONTROLS).

- Remove the access panel 1.

DRAINING THE LIQUID

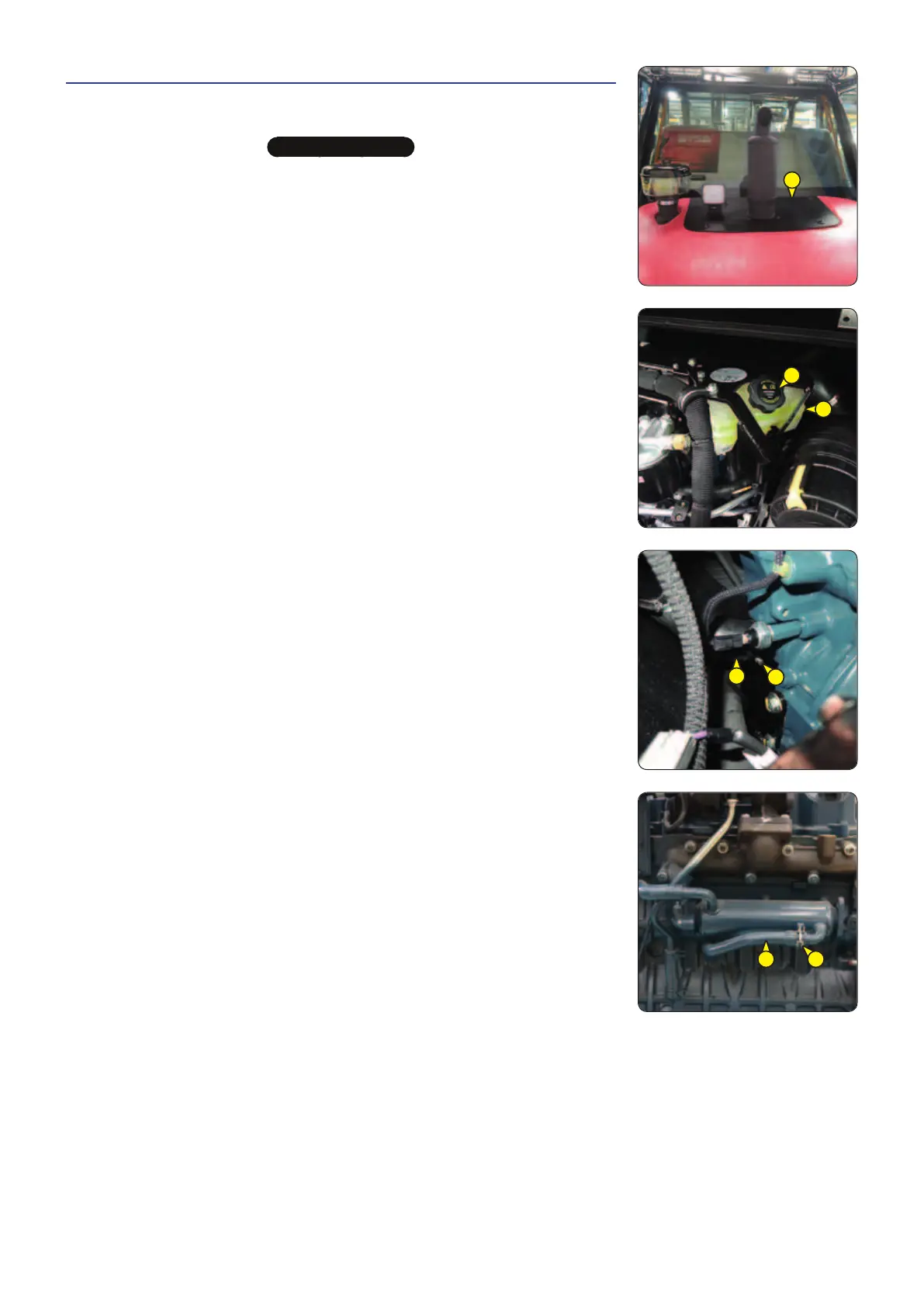

- Place a container under the hose2 of the radiator and under the hose3 of the

exhaust gas recycling valve cooler.

- Undo the clamps 4 and remove the hose 2 and the hose 3.

- Remove the filler plug5 to ensure correct drainage.

- Let the cooling circuit drain entirely while ensuring that the ports do not get clogged.

- Check the condition of the hoses and their attachments, and change if necessary.

- Rinse the circuit with clean water, or use a cleaning agent if necessary.

FILLING WITH COOLANT

- Refit the hose 2 and the hose 3.

- Slowly fill the system with the coolant (

MAINTENANCE: LUBRICANTS AND FUEL)

through the filler hole5.

- Refit the filler plug.

- Run the engine at idle for a few minutes.

- Visually check that there is no leakage in the radiator and pipes.

- Check the level and refill if necessary.

- The liquid must be at the MAXIMUM level on the expansion tank 6.

3 - 28

1

3 4

2

4

6

5

647837 M1 (A052020)

MC 18-2/18-4 D K ST5 S1

Loading...

Loading...