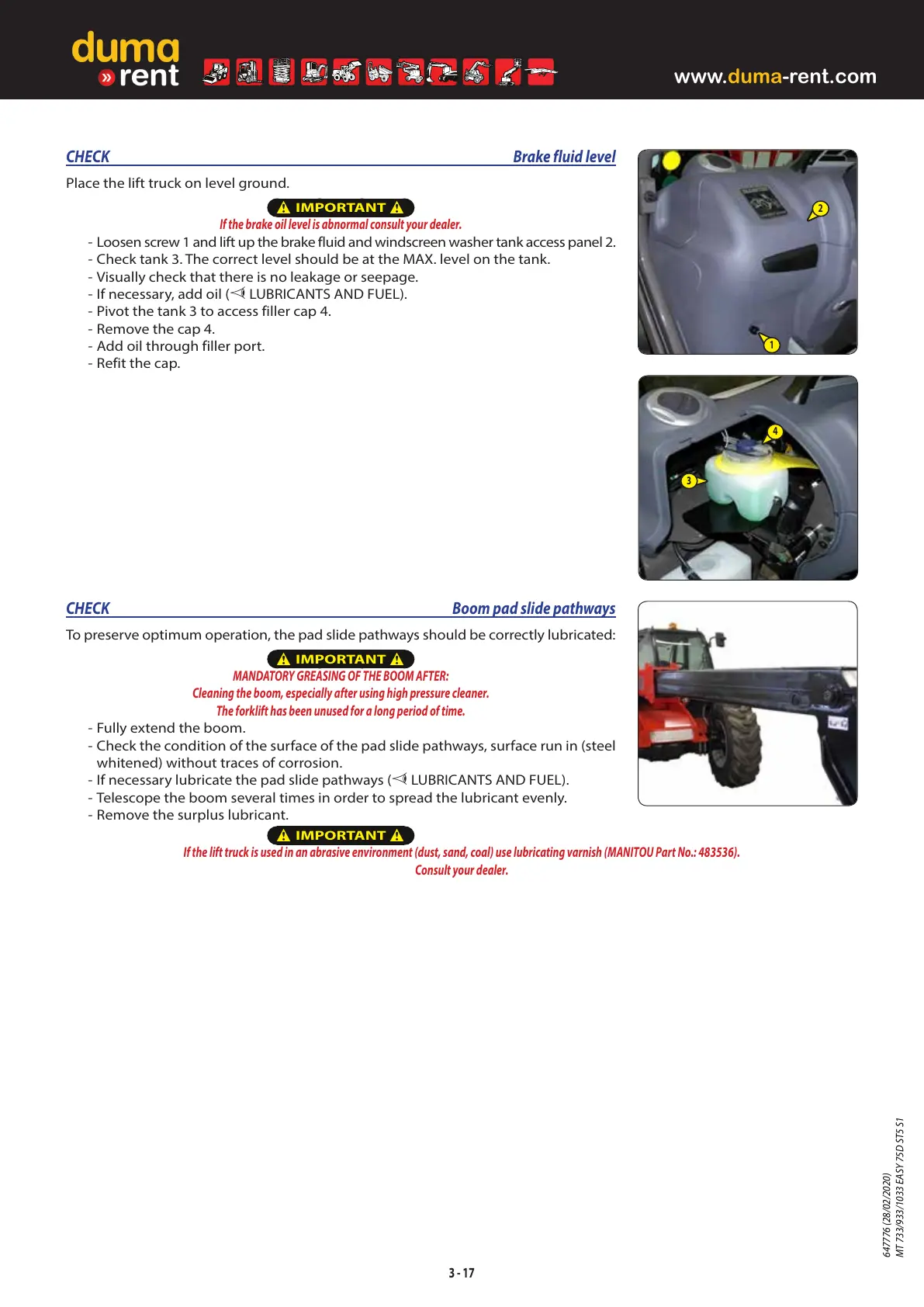

CHECK Brake fluid level

Place the lift truck on level ground.

t

IMPORTANT

t

If the brake oil level is abnormal consult your dealer.

- Loosen screw 1 and lift up the brake fluid and windscreen washer tank access panel 2.

- Check tank3. The correct level should be at the MAX. level on the tank.

- Visually check that there is no leakage or seepage.

- If necessary, add oil (eLUBRICANTS AND FUEL).

- Pivot the tank 3 to access filler cap 4.

- Remove the cap4.

- Add oil through filler port.

- Refit the cap.

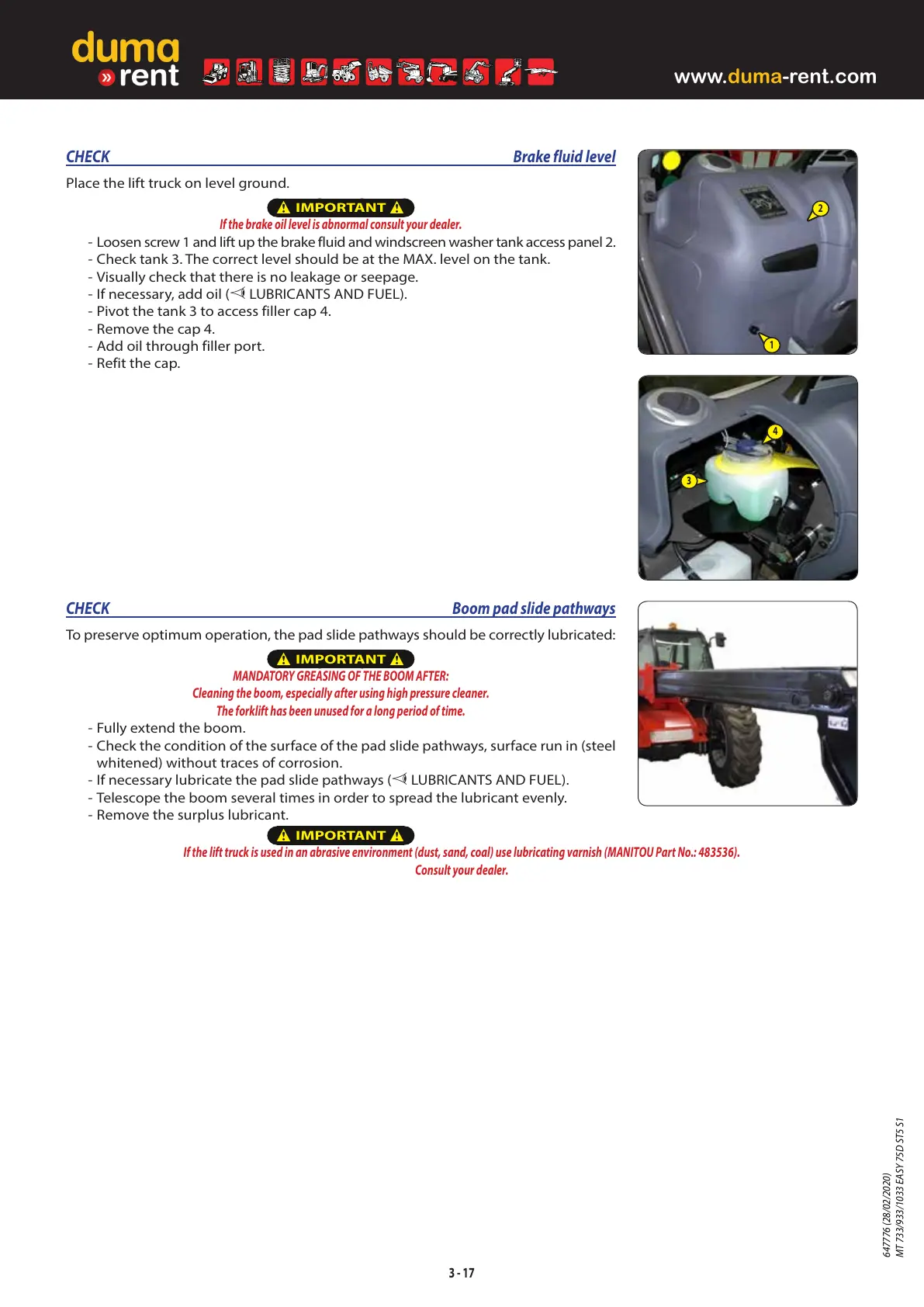

CHECK Boom pad slide pathways

To preserve optimum operation, the pad slide pathways should be correctly lubricated:

t

IMPORTANT

t

MANDATORY GREASING OF THE BOOM AFTER:

Cleaning the boom, especially after using high pressure cleaner.

The forklift has been unused for a long period of time.

- Fully extend the boom.

- Check the condition of the surface of the pad slide pathways, surface run in (steel

whitened) without traces of corrosion.

- If necessary lubricate the pad slide pathways (eLUBRICANTS AND FUEL).

- Telescope the boom several times in order to spread the lubricant evenly.

- Remove the surplus lubricant.

t

IMPORTANT

t

If the lift truck is used in an abrasive environment (dust, sand, coal) use lubricating varnish (MANITOU Part No.:483536).

Consult your dealer.

3 - 17

3

4

1

2

Loading...

Loading...