HOIST AND COUNTERWEIGHT RT540E SERVICE MANUAL

5-4 Published 4-20-2015, Control # 502-01

HOIST MAINTENANCE AND INSPECTION

It is extremely important that maintenance staff involved with

the crane inspections be made aware of the possibility that

deterioration of internal critical components within the hoist

can occur. Hoists incorporate planetary gears, multi-disc

brake assemblies and sprag clutches which do not have an

infinite service life span. Although these components have

been designed to achieve long service life, reliability can be

substantially reduced by a variety of influencing factors such

as:

• High cycle operation

• Operating in high ambient temperatures

• High external contamination, such as dusty or sandy

conditions

• Type of lubricant used

• Level of maintenance

The following routine servicing points must be carried out in

accordance with manufacture’s instructions:

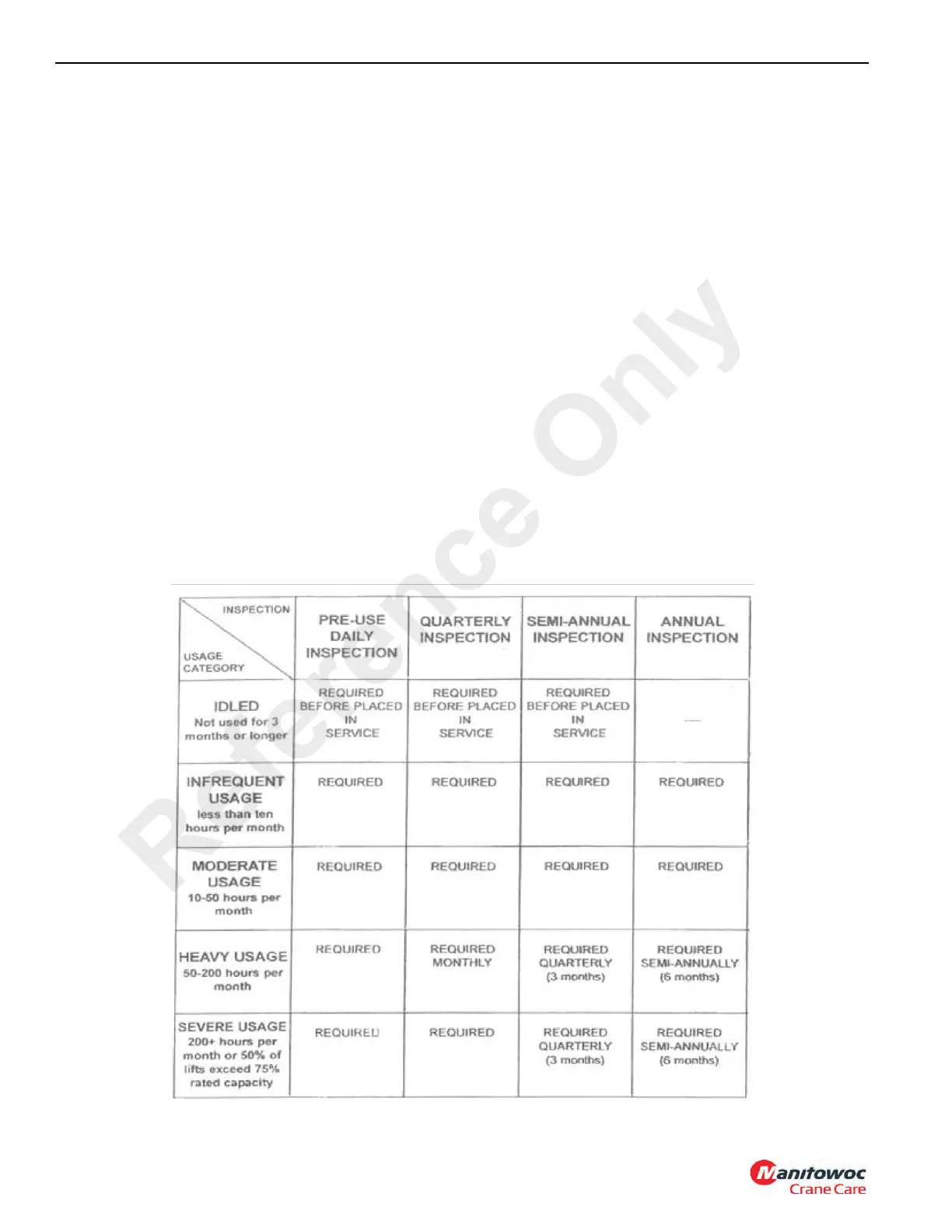

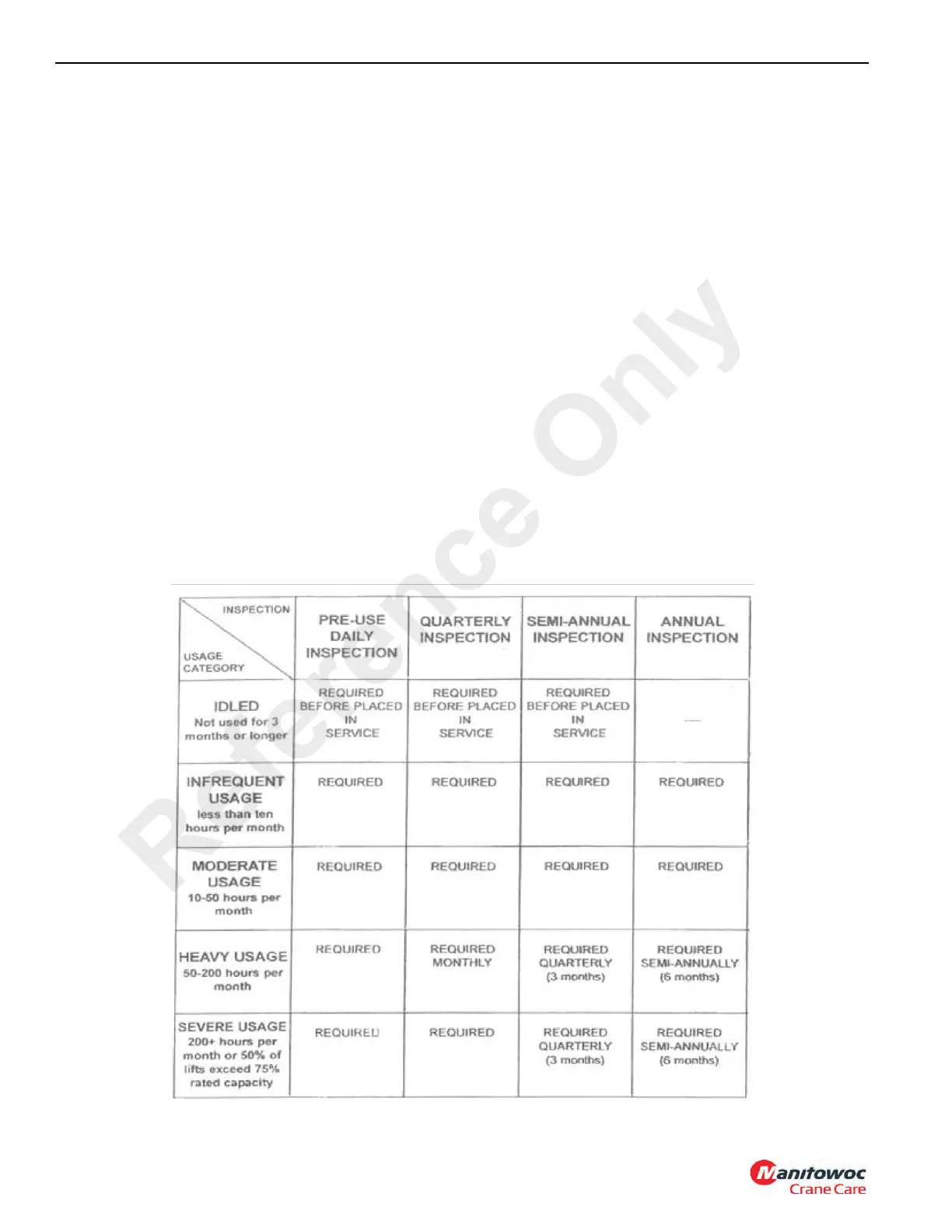

Usage and Inspection

Inspection procedures for hoists are divided into five general

categories based upon their usage or duty cycle, which in

turn determines appropriate intervals for inspections. The

usage categories must be assigned by the crane user on a

consistent crane-by-crane basis. The five crane/hoist usage

categories are as follows:

•Idled - The crane/hoist has not been used for three

months.

• Infrequent Usage - The crane/hoist is used less than

ten hours per month based on a three month average

• Moderate Usage - Crane/hoist used 10 - 50 hours per

month based on a three month average.

• Heavy Usage - Crane/hoist used 50 - 200 hours per

month.

• Severe Duty - Crane/hoist is operated more than 200

hours per month OR where 50% of the lifts exceed 75%

of the rated capacity for the hoist.

NOTE: For idled units with unknown maintenance and

repair history, it is highly recommended that the

hoist undergo a tear down inspection prior to being

placed into service.

The following chart lists the inspections that are required for

each type of usage category:

Reference Only

Loading...

Loading...