UNDERCARRIAGE RT540E SERVICE MANUAL

8-36 Published 4-20-2015, Control # 502-01

Installation

1. Place the cylinder in the beam.

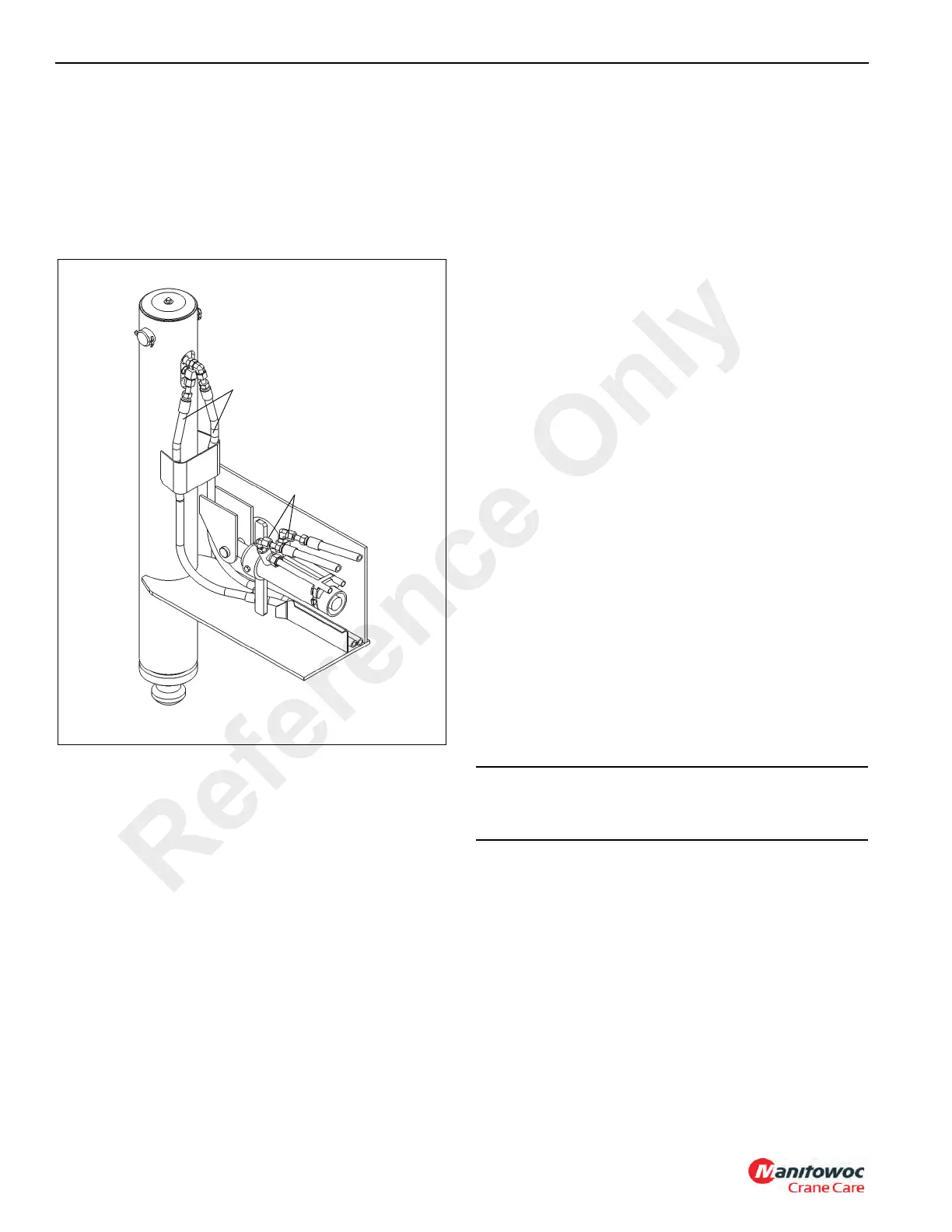

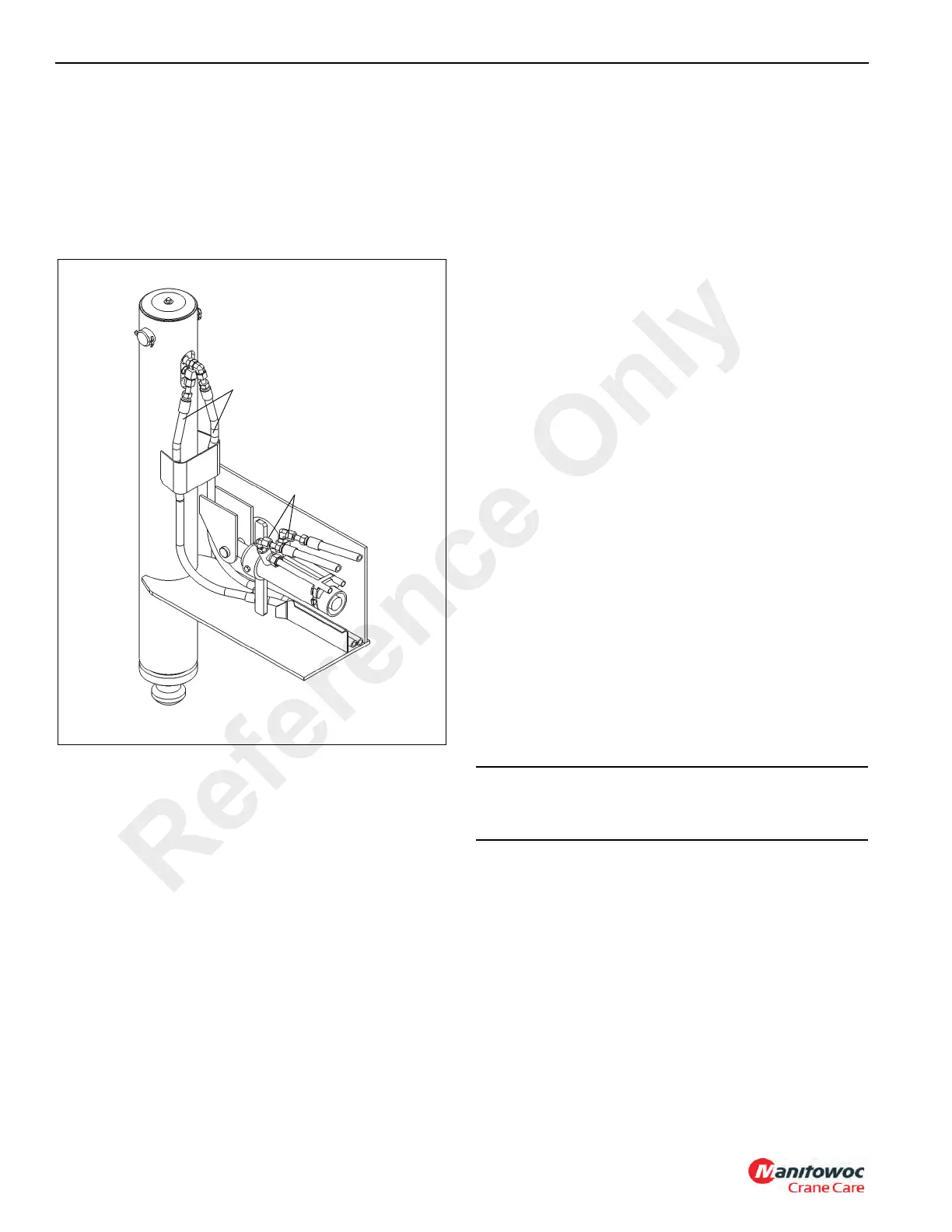

NOTE: Keep hydraulic fittings and hoses close to angles

shown (Figure 8-33) and as low as possible to

prevent rubbing with the beam top plate and side

plate, and for proper tracking during beam

extension and retraction.

2. Position the extension cylinder so the hydraulic ports on

the rod end of the cylinder can be accessed. Connect

the hydraulic hoses to the ports as tagged during

removal.

3. Push the cylinder into the outrigger beam. Align the

cylinder rod with the clevis in the beam. Apply anti-seeze

to the clevis pin and secure in place with the clevis pin

and cotter pin.

4. Install the outrigger beam. Refer to OUTRIGGER BEAM

- INSTALLATION in this section.

Functional Check

1. Activate the hydraulic system; extend and retract the

outrigger.

2. Observe the operation of the outrigger beam.

3. Check the hydraulic connections for any evidence of

leakage.

Jack Cylinder

Description

Four jack cylinders are used on the crane, one at the end of

each outrigger beam. The jack cylinders provide the force for

the outrigger beam’s vertical movement. The cylinder weighs

approximately 64.6 kg (142.4 lb).

Maintenance

NOTE: Refer to CYLINDERS in Section 2 - HYDRAULIC

and PRESSURE SETTINGS for Disassembly and

Assembly of the cylinders.

Removal

1. Extend the outrigger beam slightly for improved access

to the jack cylinder; shut down the engine.

2. Tag and disconnect the hydraulic hoses from the jack

cylinder. Remove the fittings from the ports. Cap or plug

all openings.

3. Remove the nut and washer and remove the cylinder

cap.

4. Place a jack capable of supporting the weight of the jack

cylinder at the base of the cylinder barrel. Jack up the

cylinder just enough to relieve any pressure on the

cylinder retaining pin.

5. Remove the cotter pins securing the cylinder retaining

pin and remove the cylinder retaining pin and cylinder

cap retaining bracket.

6. Jack the jack cylinder up just enough to insert the

retaining pin back into the cylinder. Insert the retaining

pin into the lugs on the cylinder and secure the pin in

place with the cotter pins.

7. Fasten a nylon strap onto the cylinder retaining pin and

use an adequate lifting device to lift the jack cylinder out

of the tube on the beam assembly.

Installation

1. Apply grease (EPMPG) to the ID of the jack cylinder

support tube.

2. If removed, install wear ring in groove in bottom of

support tube and in groove at top on jack cylinder.

3. Place a jack beneath the cylinder tube on the outrigger

beam. Using the same method as described under

REMOVAL, lower the jack cylinder into the cylinder tube

on the outrigger beam until the retaining pin is just above

FIGURE 8-33

Fittings

Hoses

8488

CAUTION

Use a nylon strap to remove the cylinder. This will ensure

the retaining pin is not damaged.

Reference Only

Loading...

Loading...