Published 4-20-2015, Control # 502-01 7-23

RT540E SERVICE MANUAL POWER TRAIN

Troubleshooting Procedures

Removal

1. Extend and set the outriggers just enough to take up the

slack in the outrigger pads. Chock the wheels.

2. Position the boom over the side and stop the engine.

3. Remove the engine and transmission/torque converter

from the crane as an assembly. Refer to Engine, page 7-

1 in this Section.

4. Remove the hydraulic pumps from the transmission/

torque converter. Cover all openings. Refer to Hydraulic

Pumps, page 2-14 for removal of the pump.

NOTE: The transmission/torque converter weighs

approximately 374 kg (824.5 lb) dry.

5. Attach an adequate lifting device to the transmission/

torque converter and take up any slack.

6. Remove the hardware securing the drive plate assembly

to the flywheel.

7. Remove the hardware securing the transmission/torque

converter housing to the engine flywheel housing.

Installation

NOTE: The transmission/torque converter assembly

weighs approximately 374 kg (824.5 lb) dry.

1. If a new transmission/torque converter is to be installed,

remove all fittings and brackets from the old one and

install them in the same locations on the new

transmission/torque converter.

2. Install the piston and single section hydraulic pumps on

the transmission/torque converter. Refer to Hydraulic

Pumps, page 2-14 for installation of the hydraulic pump.

3. Position the transmission/torque converter to the engine

with the lifting device.

4. Remove all burrs from the flywheel mounting face and

nose pilot bore. Clean the drive plate surface with

solvent (Figure 7-11).

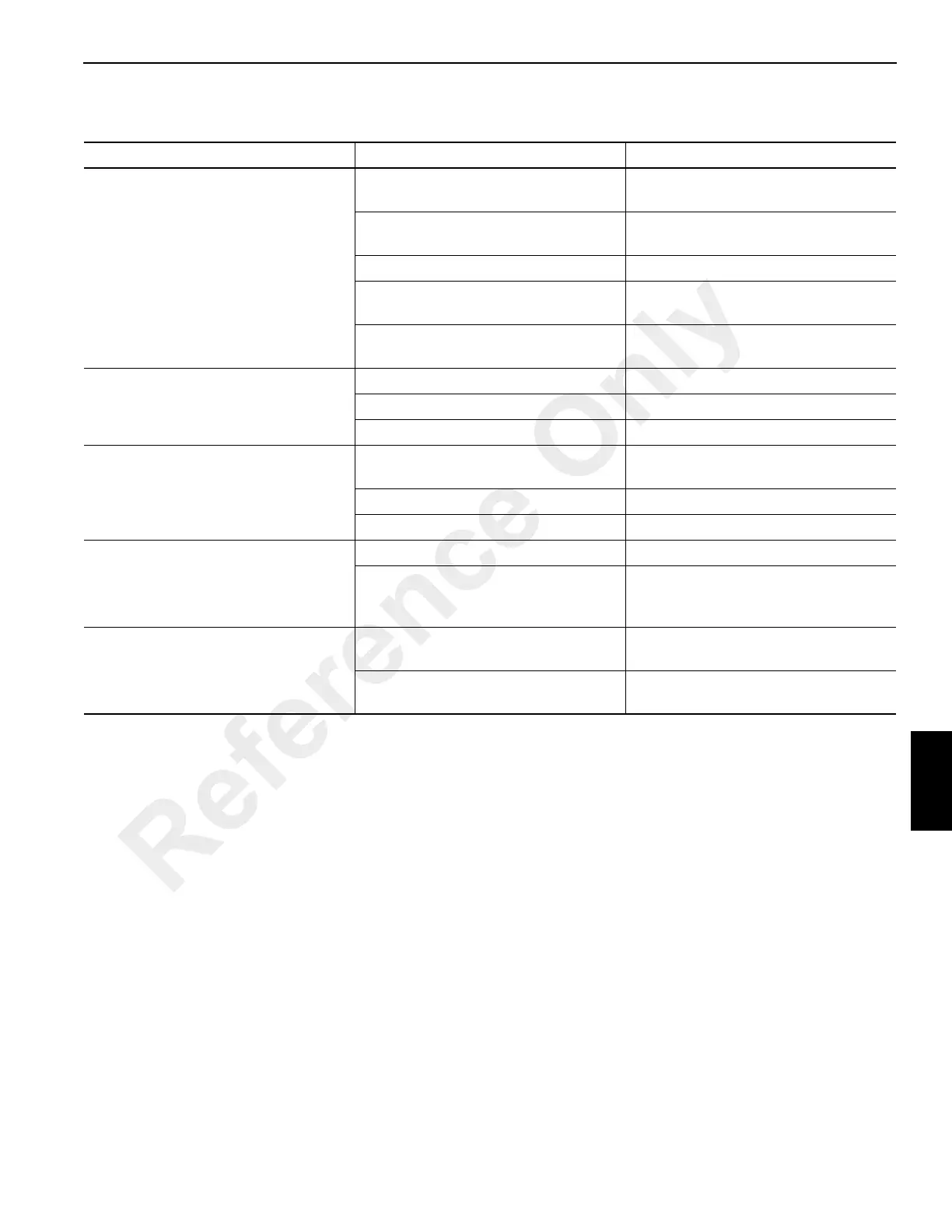

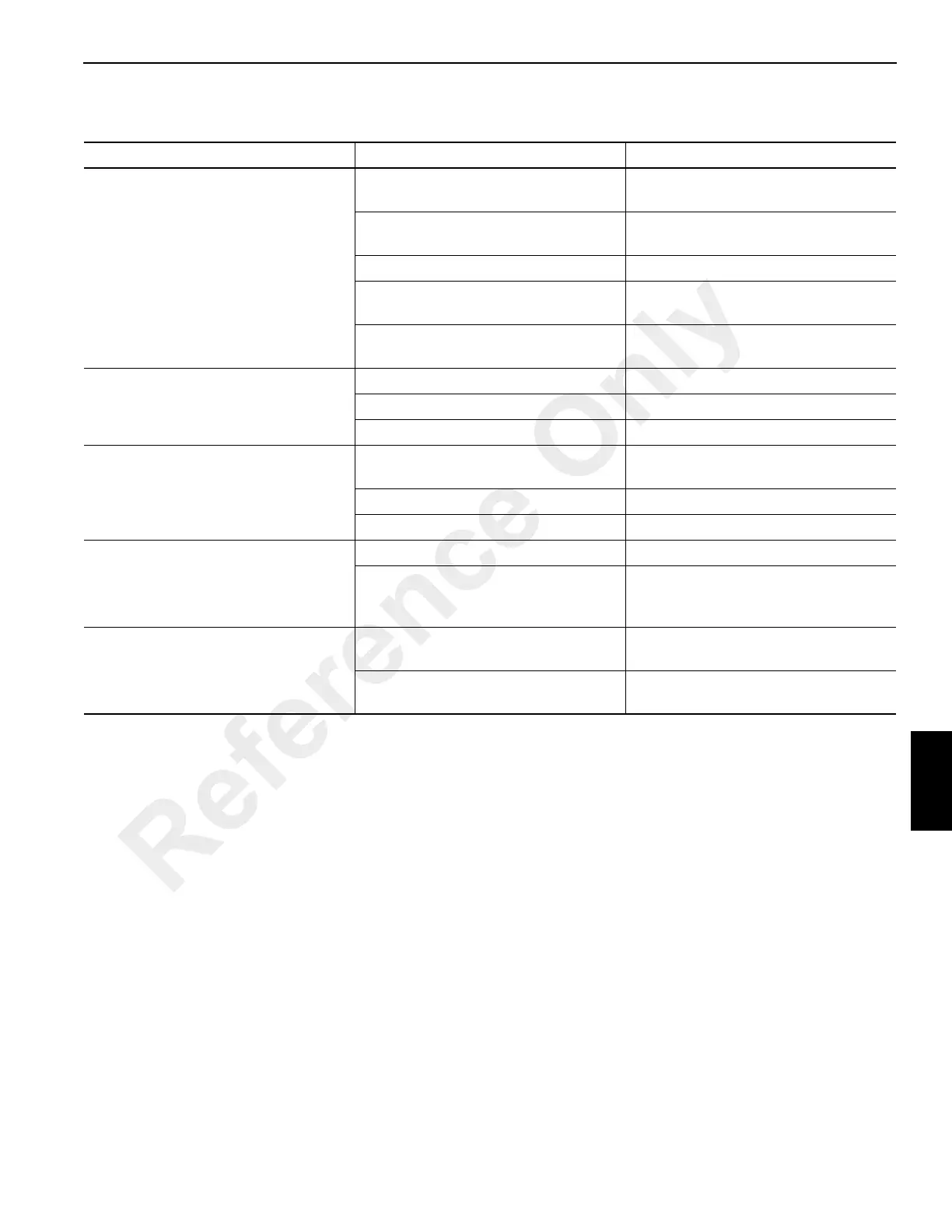

SYMPTOM PROBABLE CAUSE REMEDY

1. Low clutch pressure. a. Low oil level. a. Fill to proper level. Refer to

LUBRICATION (pg 9-1).

b. Clutch pressure regulating

valve spool stuck open.

b. Clean valve spool and housing.

c. Faulty charging pump. c. Replace pump.

d. Broken or worn clutch shaft or

piston sealing rings.

d. Replace clutch shaft or sealing

rings, as applicable.

e. Clutch piston bleed valve stuck

open.

e. Clean bleed valves thoroughly.

2. Low converter charging pump

pressure.

a. Low oil level. a. Fill to proper level.

b. Suction screen plugged. b. Clean suction screen.

c. Defective oil pump. c. Replace pump.

3. Overheating. a. Worn oil sealing rings. a. Remove, disassemble, and

rebuild converter assembly.

b. Worn oil pump. b. Replace pump.

c. Low oil level. c. Fill to proper level.

4. Noisy converter. a. Worn oil pump. a. Replace pump.

b. Worn or damaged bearings. b. A complete disassembly will be

necessary to determine what

bearing is faulty.

5. Lack of power. a. Low engine RPM at converter

stall.

a. Tune engine and check

governor.

b. See “Overheating” and make

same checks.

b. Make corrections as explained

in “Overheating.”

Reference Only

Loading...

Loading...