4A-1790-13645--2 495 POWERHEAD

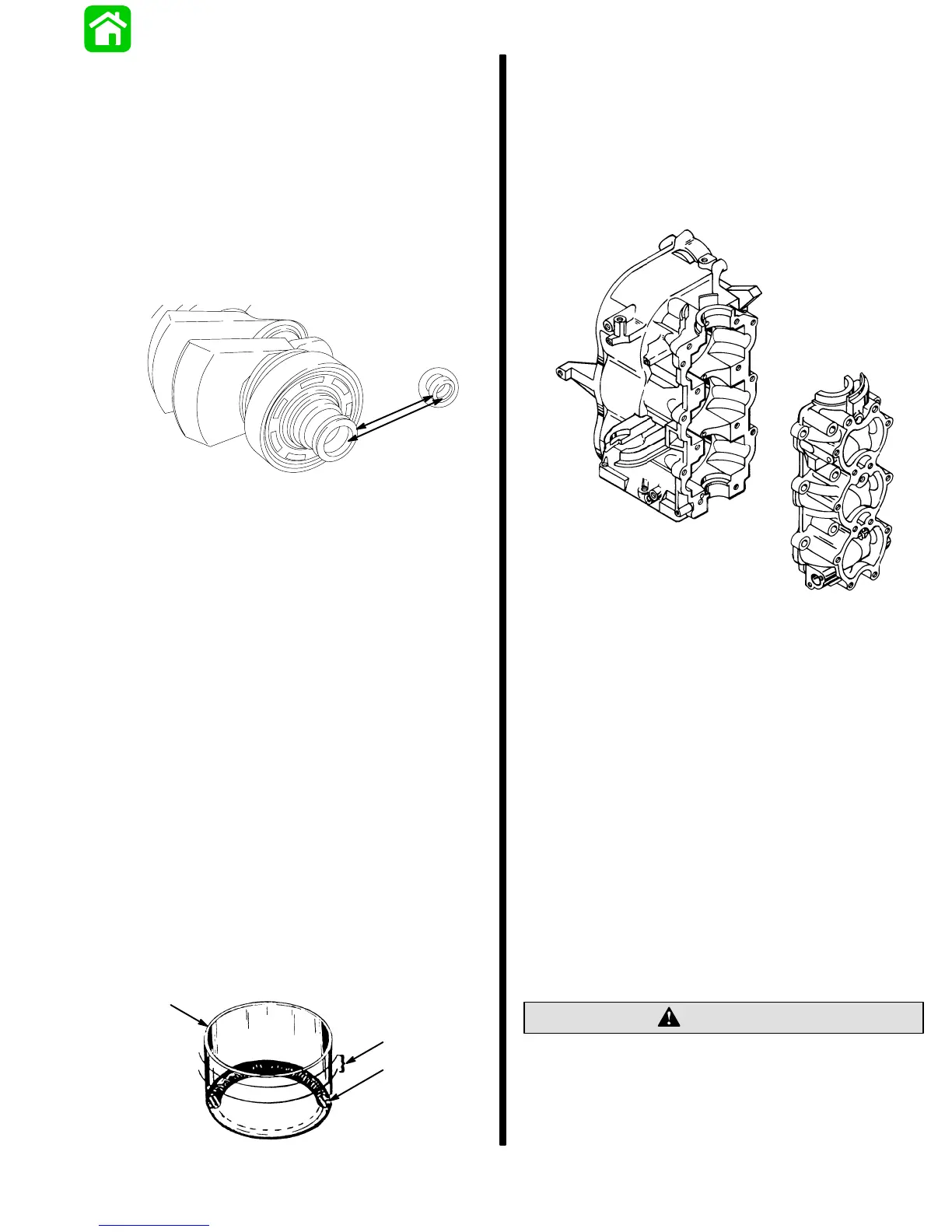

Seal carrier is press-fitted into the spline end of crank-

shaft.

NOTE:

Seal should be replaced as a routine proce-

dure without regard to appearance, to prevent water

leakage into crankshaft/driveshaft splines.

1. Remove seal by prying out of carrier, using an awl.

2. Inspect seal carrier for damage or looseness.

3. If replacement of carrier is necessary, use a pliers

to pull carrier from crankshaft, or tap gently off with

screwdriver and mallet.

20037

a

b

a - Seal Carrier

b - Seal

- OR -

Some models may be equipped with the following

sleeve (b), which retains an O-ring seal (c). The sleeve

is pushed over the crankshaft end until it bottoms-out

on a crank flange, leaving space for the O-ring between

the sleeve lip and the end of the crankshaft. Pop out the

O-ring with an awl - replace the O-ring seal.

IMPORTANT: The End Cap (lower) inside seal

rides on the “wear sleeve” (area “a”). If the outer

surface of the sleeve (in area “a”) is grooved or

corroded/pitted, replace by pulling off the sleeve

with pliers--it may be necessary to heat the sleeve

to release the Loctite sealant. Replace O-ring

AFTER wear-sleeve is installed on crankshaft.

To install the sleeve, apply Loctite 271 to the crank-

shaft; align sleeve squarely with crankshaft, place a

block of wood over end of sleeve, and tap lightly until

it bottoms-out. Wipe off excess sealant. The sleeve is

lightweight (31-gauge) stainless steel - DO NOT col-

lapse the end contour or otherwise distort its shape.

Align squarely - Tap gently!

a

b

c

Cleaning and Inspection

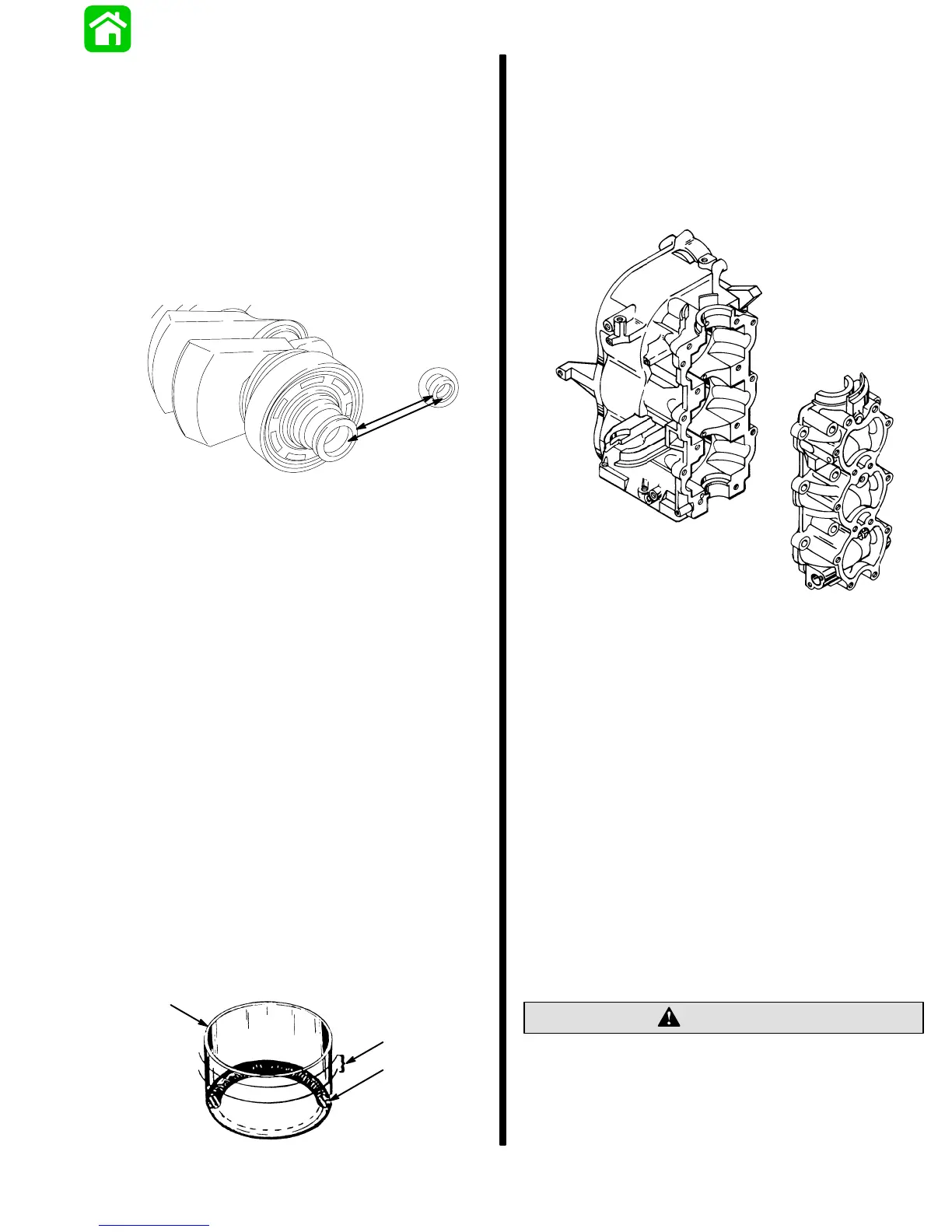

Cylinder Block and Crankcase Cover

IMPORTANT: Crankcase cover and cylinder block

are a matched, line-bored assembly and never

should be mismatched by using a different crank-

case cover or cylinder block.

1. Inspect cylinder block and crankcase cover for

cracks or fractures.

2. Check gasket surfaces for nicks, deep grooves,

cracks and distortions that could cause compres-

sion leakages.

3. Check that all water passages in cylinder block

are not obstructed. Check locating pins in cylinder

block that they are tight.

4. Check crankcase cover fuel/bleed passages that

they are not obstructed. Verify that check valves

in crankcase cover are not damaged.

5. Thoroughly clean cylinder block and crankcase

cover. Verify that all sealant and old gaskets are

removed from matching surfaces. Clean all car-

bon deposits from exhaust ports.

6. Inspect spark plug holes for stripped or damaged

threads.

If crankcase cover and cylinder block is to be

submerged in a very strong cleaning solution, it

will be necessary to remove the crankcase cover

cylinder block bleed system from cover/cylinder

block to prevent damage to hoses and chec

valves.

CAUTION

Loading...

Loading...