68

The quantity of oil to use in each of the respective gearboxes is determined by the filling marks on the dipstick

and the guide quantity to the amount of oil required for the particular gearbox is given approximately in the table

below. There are grooves marked in the dipstick with Figures 5.2 (3) and 5.3 (3) showing the upper level and

Figures 5.2 (4) and 5.3 (4) showing the lower level.

McConnel gearboxes are recommended to be filled with:

Splitter Gearbox - SAE EP80-90W or GL-4/GL-5 grade oil.

Rotor Gearboxes – 85W-140 grade oil.

Any different or higher SAE grade of oil is not recommended.

2.65 litres (4.66 pints) 2.65 litres (4.66 pints) 2.65 litres (4.66 pints)

TBC TBC TBC

N/A TBC TBC

TBC TBC TBC

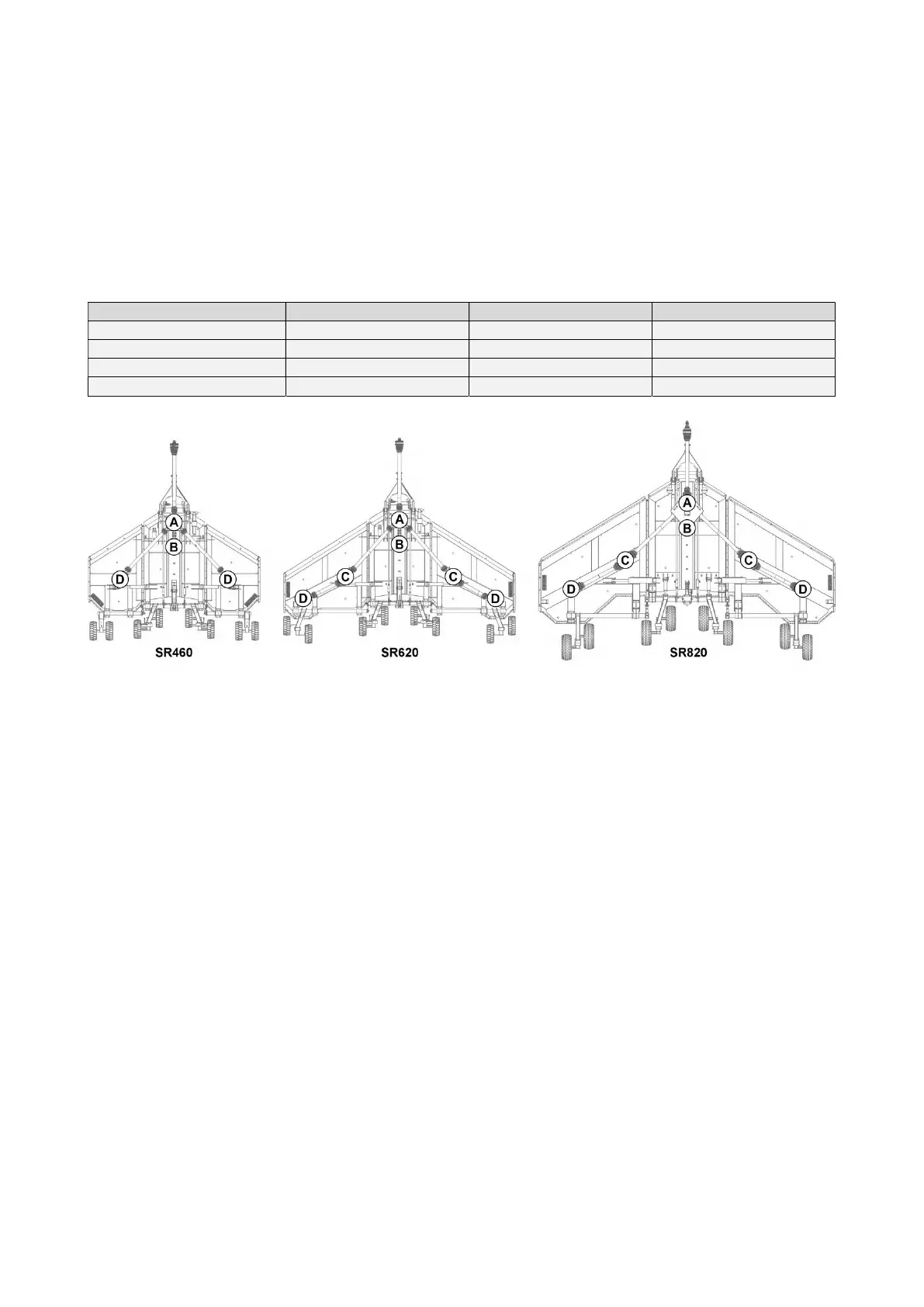

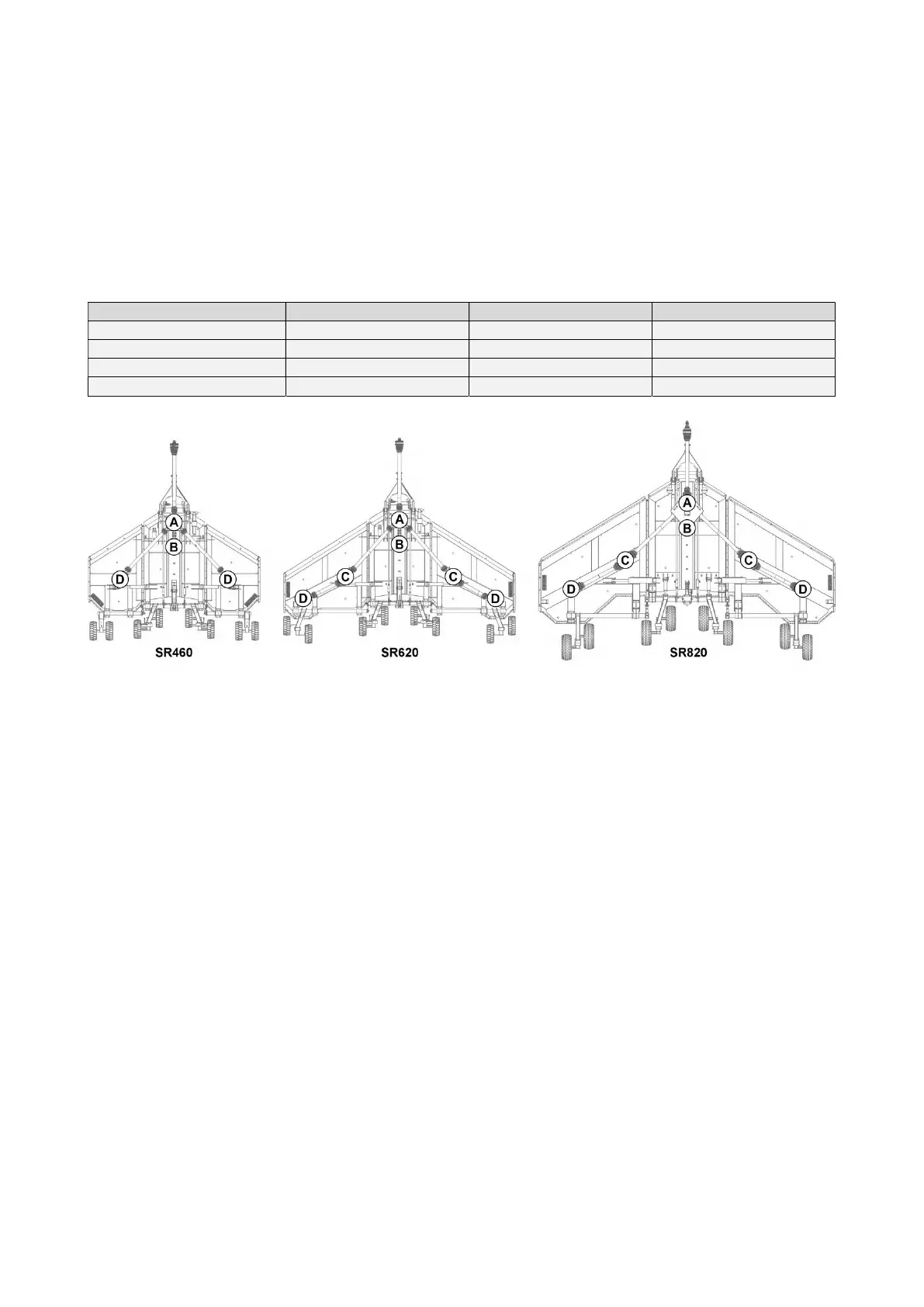

Table 5.1 – SR460/620/820 Gearbox Oil Capacities

Figure 5.1 - SR460/620/820 Gearbox Oil Capacity Locations

Changing the oil regularly prevents problems associated with deterioration, moisture build up in the oil and the

potential presence of metallic particles which form early in the machines life. Oil changes are recommended on

SR460/620/820 machines after the first 50 hours, and then every 500 hours thereafter.

To drain the oil, each of the gearboxes is fitted with a drain plug. With reference to Figures 5.2 (2) and 5.3 (2),

the locations of these drain plugs can vary. If there are facilities to vacuum draw the oil out of the respective

gearbox, the oil can be changed through the fill hole/dipstick location instead which is considerably easier.

The positioning of the dipstick can vary between gearboxes to check the oil level, due to their engineering

restrictions; see Figures 5.2 (1) and 5.3 (1). However, they should always be at the top. The drain plugs for

gearboxes are always located near the bottom of the gearbox; see Figure 5.3.

The gearbox should not require additional lubricant unless the box is cracked, or a seal is leaking. It is

recommended that the oil level is checked every day before operation and additional oil added, if required, to

bring it up to the upper level mark, see Figures 5.2 (3) and 5.3 (3), before proceeding to use the machine. At

all times the oil level should be above the lower fill mark; see Figures 5.2 (4) and 5.3 (4) as otherwise permanent

damage could be caused to the gearbox. The splitter gearbox guard has a cut-out in order to check the oil level

without having to open the guard.

Loading...

Loading...