McHale V Series Baler

101

9.15.4 Brake adjustment

Machines fitted with brakes, either air or hydraulic, must be initially checked after the

first 50 hours of use and every 100 hours or yearly thereafter (whichever comes first).

The following is the procedure for checking brakes:

WARNING: Ensure safety before working on brake adjustment

Before attempting to carry out brake adjustment, ensure that the tractor

engine has been switched off and the key removed. Testing should be

conducted with the hand brake ‘off’ on both the machine and the tractor

and a second trained person will be required to activate brakes from the

tractor. Also ensure machinery can’t roll by parking machinery on level

ground with wheels chocked. Always wear protective clothing and

gloves.

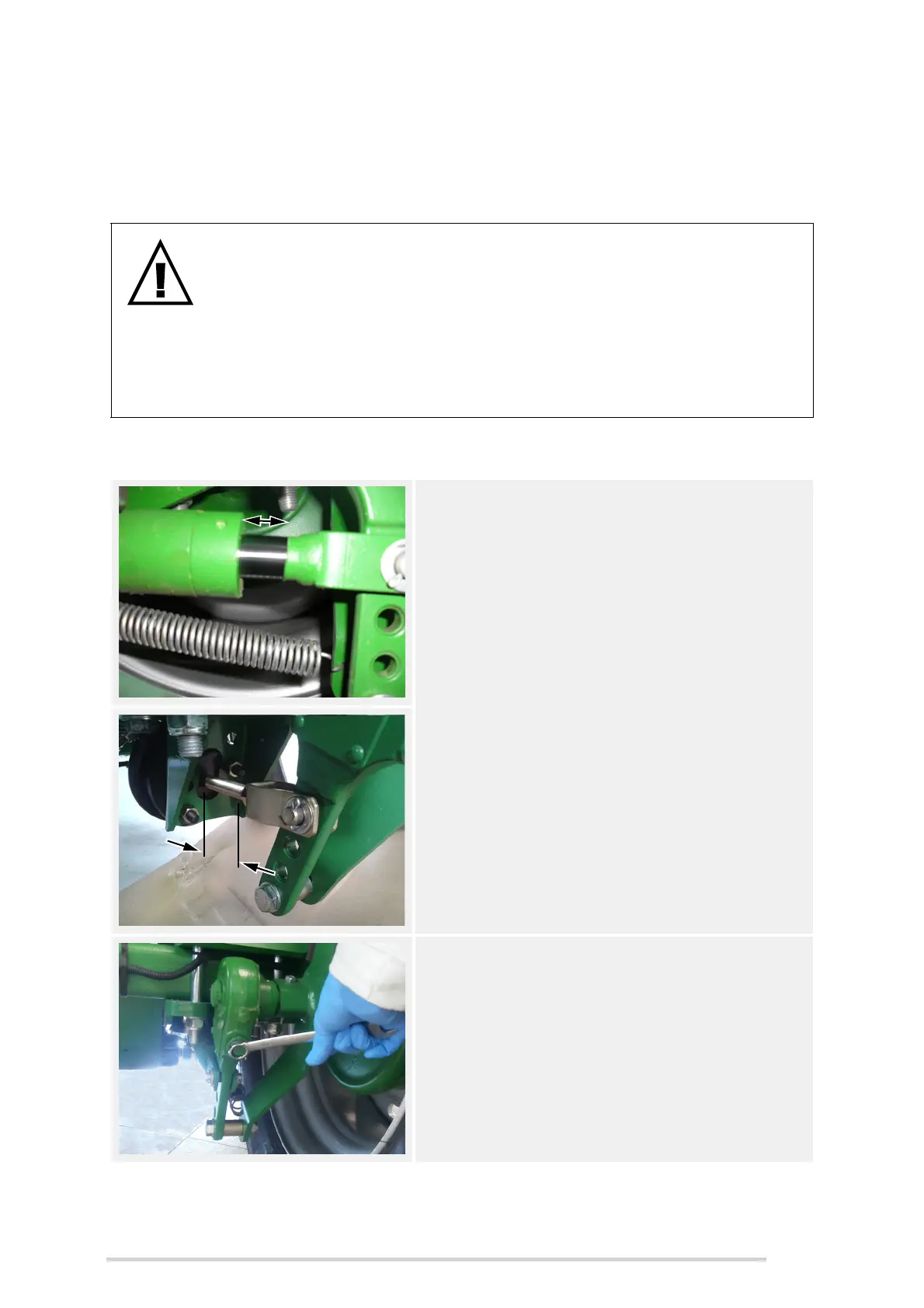

1. Check dimension ‘X’ before applying brakes

and again when brakes are applied. The

value for ‘X’ should be between 12 and

18 mm.

On hydraulic brakes (top picture) this is

usually the amount of exposed chrome

visible on cylinder rod.

On air-brake systems (bottom picture),

some fixed reference point must be used to

measure the actuator movement.

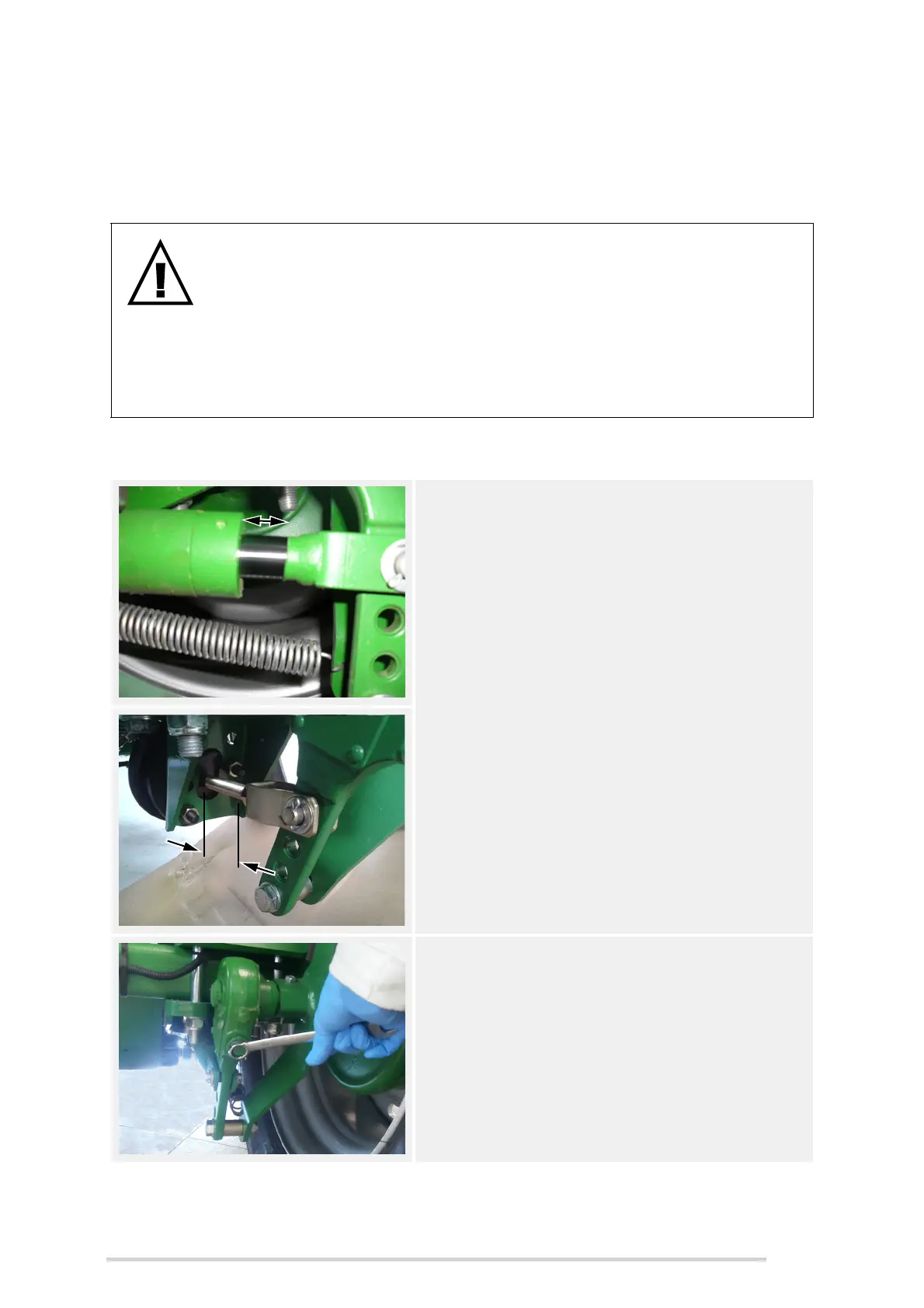

2. If the value for ‘X’ is not within this

12 - 18 mm range, then the brake can be

adjusted using the adjuster screw, as

shown. Using a 14 mm spanner, turn the

adjuster screw clockwise to reduce the

value and anti-clockwise to increase. Apply

the brake again to check the measurement

and repeat this procedure until the

movement is within the designated range.

Loading...

Loading...