7 Sterilization

25

7 Sterilization

Important information regarding routine operation

Please comply with the recommendations issued by the Robert-Koch-Institute (RKI) and the information

contained in DIN 58946-7 (Germany).

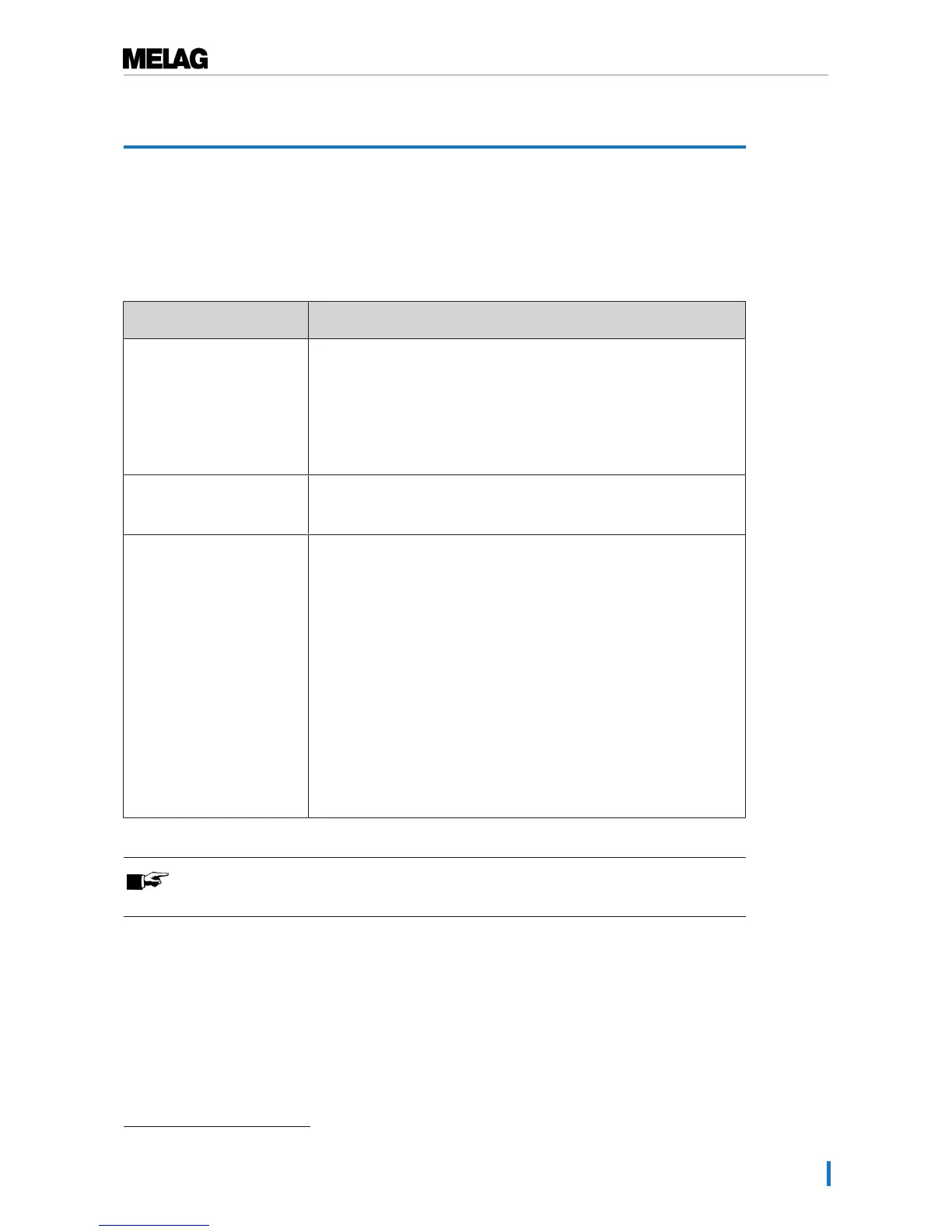

Manufacturer's recommendation for the routine operation of Class B steam sterilizers

1

When is it necessary to

make checks?

How should the checks be made?

Once per working day ▪ Visual check of the door seal and the door seal for damage.

▪ Check the operating agents (electricity, feed water and water

connection if necessary).

▪ Check the documentation media (printer paper / computer / network)

We recommend performing the steam penetration test with

MELAcontrol/MELAcontrol PRO in the Universal-Program (test

system in accordance with DIN EN 867-5).

Once a week ▪ Vacuum test

Tip: In the mornings before starting work - the steam sterilizer must

be cold and dry.

Batch-related tests With “Critical B” instruments:

▪ MELAcontrol/MELAcontrol PRO must be used as batch control with

every sterilization cycle.

With “Critical A” instruments:

▪ The process indicator (type 5 in accordance with DIN EN ISO 11140)

must be used as batch control with every sterilization cycle.

With “Critical A + B” instruments:

▪ MELAcontrol/MELAcontrol PRO must be used as batch control with

every sterilization cycle.

This simplifies the working procedure and increases security. You can

omit the daily steam penetration test with MELAcontrol/MELAcontrol PRO

(see above). The use of another test system in accordance with DIN EN

867-5 is possible. The number of the available test systems means that

MELAG is not able to provide technical support when using a different

system.

The indicator test strips used need not be stored.

PLEASE NOTE

The results of the tests must be documented.

1)

in accordance with the current recommendations from the Robert-Koch-Institut

Loading...

Loading...