11 Maintenance

61

Cleaning the feed and waste water side

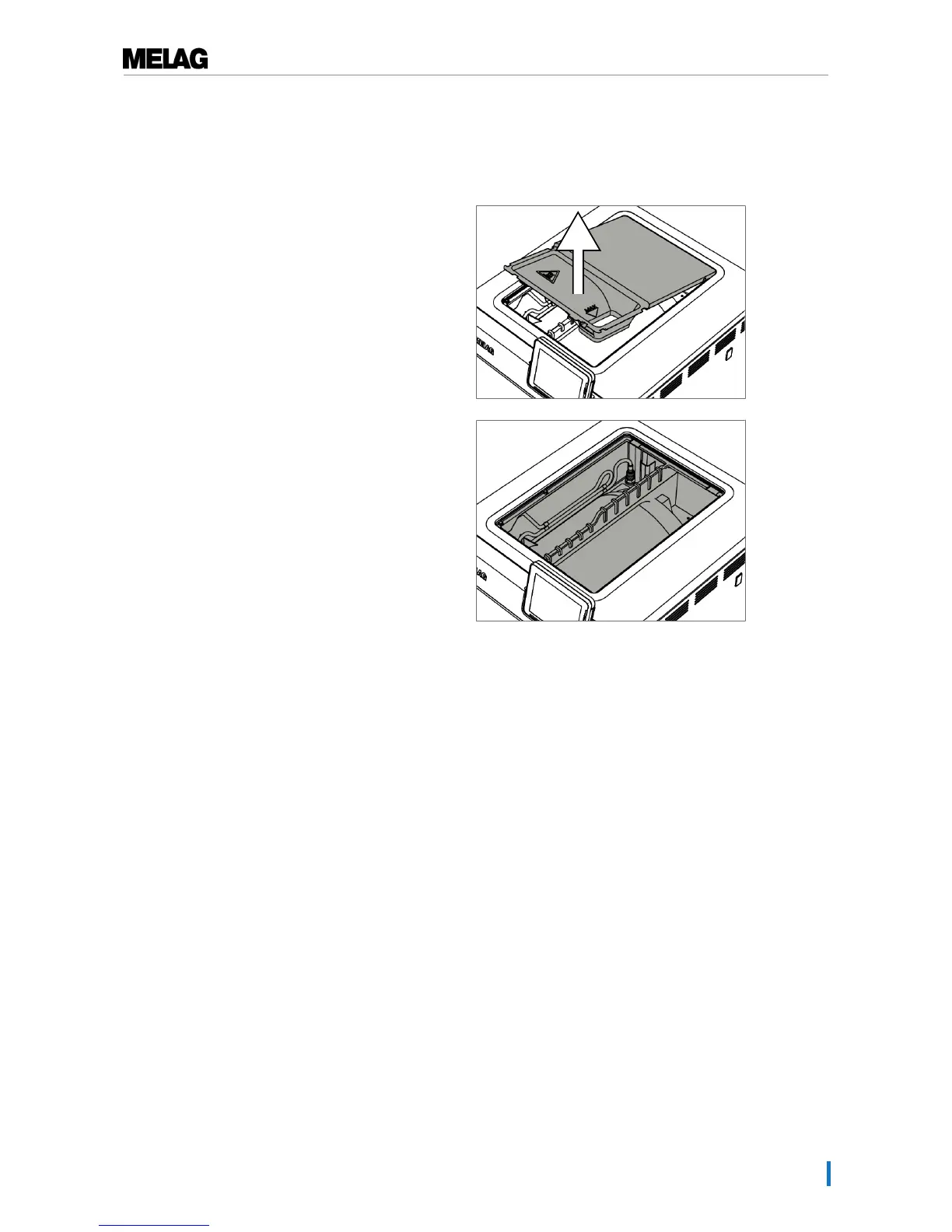

You can remove the cover of the storage tank completely to clean the chambers of the internal storage

tank.

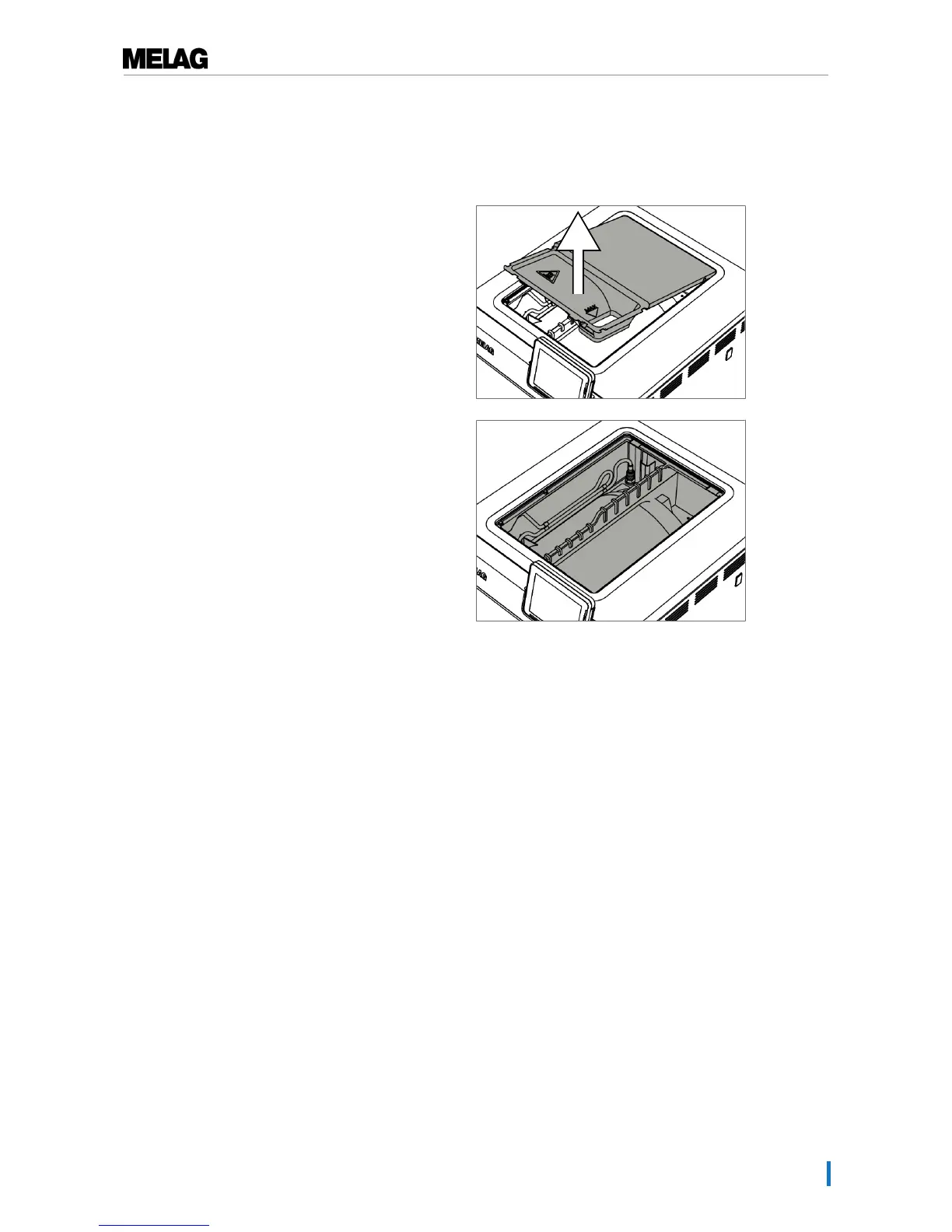

1. Remove the fore tank lid.

2. Grasp the cover on the filling opening and then lift the

cover upwards a little.

3. Remove the cover from the rubber seal completely.

Avoiding staining

Only after cleaning instruments properly prior to sterilization is it possible to avoid residue from the load or

the instrument decontamination from being released during sterilization. Loosened dirt residue can clog

the filter, nozzles and valves of the steam sterilizer and deposit themselves on the instruments and

chamber as deposits and stains.

All steam-conducting parts of the steam sterilizer consist of non-rusting material. This rules out the

possibility of stain or rust development being caused by the steam sterilizer. The development of rust is

always extraneous rust.

Incorrect instrument decontamination can result in the accretion of rust even on stainless steel instruments

of leading manufacturers. Often, an instrument which drops rust can suffice to cause the development of

rust on another instrument or in the steam sterilizer. Remove foreign rust from the instruments using a

chlorine-free stainless steel cleaning agent (see section Cleaning [}page 59]) or send the damaged

instruments to the manufacturer.

The extent of stain accretion on the instruments is also dependant on the feed water used for steam

generation.

Oiling the door spindle

Oil the door spindle every two months as follows:

1. Clean the spindle with a non-fuzzing cloth.

2. Place two drops of oil in the bushing on the door of the steam sterilizer from the oil can included in the

scope of delivery (art. no. 27515).

Instructions for oiling the door spindle are printed on the inside of the door of the steam sterilizer.

Loading...

Loading...