MAINTENANCE

5-3

MA-5052-ENG MACRO SERIES MELTER MANUAL

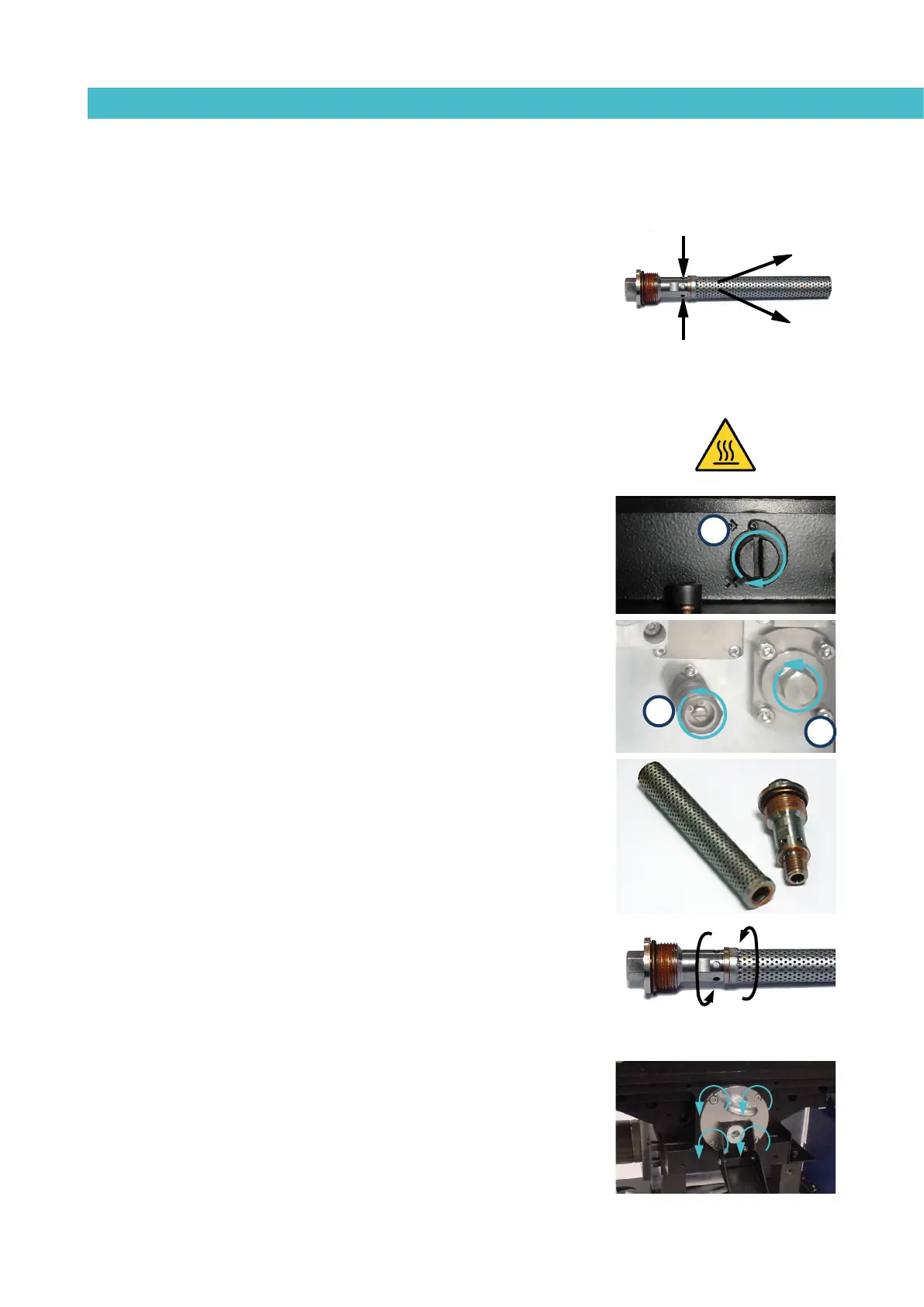

No rule exists for determining when to change the filter. Several factors

influence this decision:

• The type and purity of the adhesives used.

• The adhesive work temperatures.

• Adhesive consumption in relation to the time it spends in the tank.

• Changes in the type of adhesive used.

In any case, we recommend checking and cleaning the filter at least every

1000 hours of operation (melter equipment turned on).

Warning: Always use protective gloves and glasses. Risk of burns.

To change the filter:

1. Close the by-pass valve from the tank to the distributor.

2. Depressurize the system using the purge valve.

3. Using a 15 mm wrench, unscrew the hexagonal filter cap and remove it.

4. Unscrew the filter cartridge in a clockwise direction.

5. Depending on the dirt inside the cartridge, clean it or dispose of it

directly, abiding by any existing waste regulations.

6. Screw back the cartridge back onto the filter cap in a counterclockwise

direction.

7. Replace the filter seal if damaged.

8. Place the assembly inside the distributor once more and tighten as

much as possible.

9. Continue with normal operation.

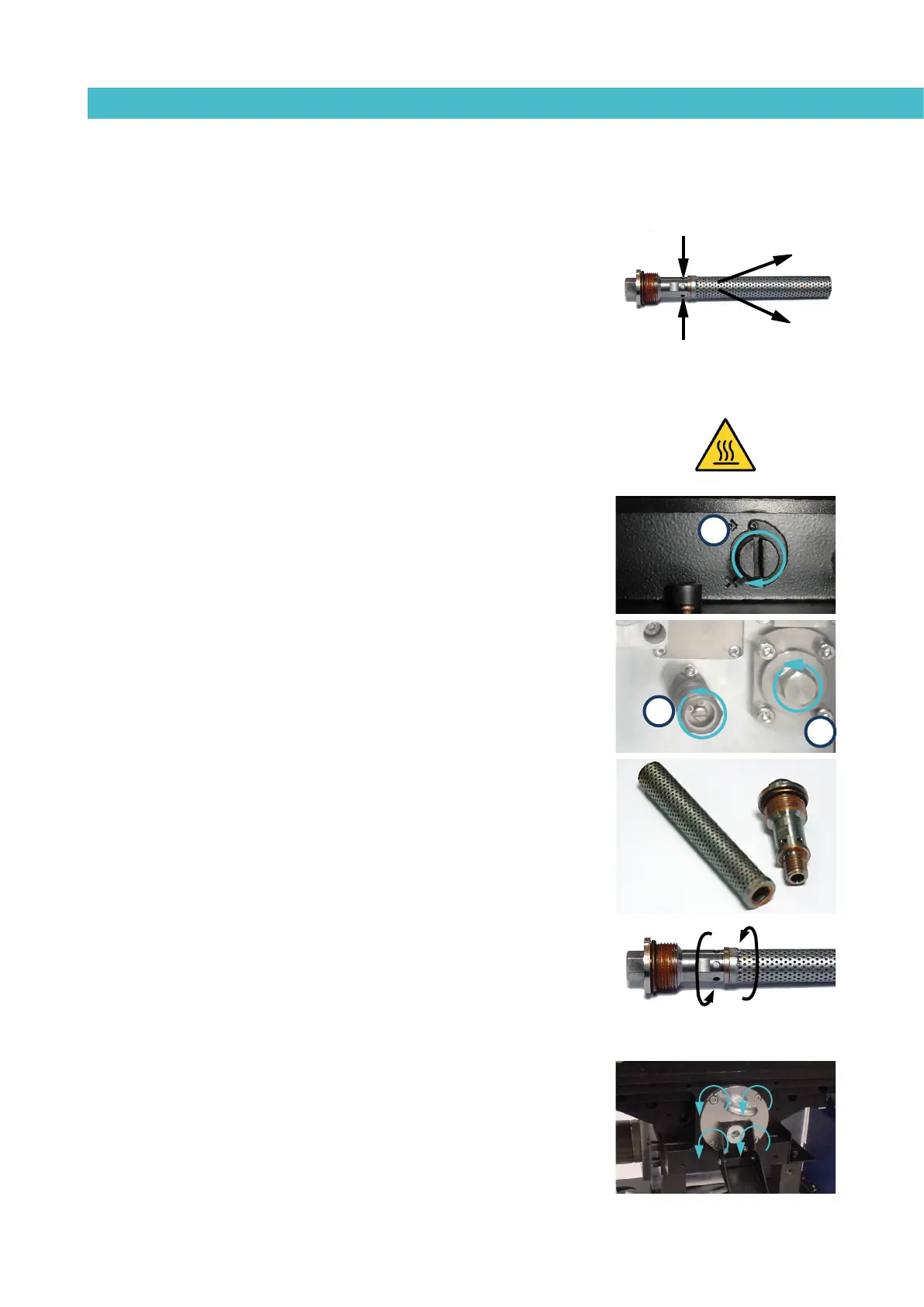

Tank filter

At the manifolds input there is a coarse filter inside the tank itself. This filter

acts as a first step stoping dirty and parts from the outside.

This filter includes an output to empty the tank for cleaning it or changing the

adhesive. Therefore to clean the filter the tank must to be empty previously.

To remove the filter:

2

3

1

Loading...

Loading...