remain active until either another transducer is

selected to be active (by local or remote command),

or the AUTORANGE is enabled. Relief valves have

been incorporated to prevent damage due to fast

pressure transients.

To enable AUTORANGE:

Press [2nd]

[3] LIMITS

[=]

[+] or [–] until the display shows:

SELECT ACTIVE RANGE (USE +,-,=,CE)

ANY INTERNAL TRANSDUCER (AUTORANGE)

then press [=] to enable AUTORANGE.

To disable AUTORANGE:

Press [2nd]

[3] LIMITS

[=]

[+] or [–] until desired transducer is

displayed

then press [=] to range-hold using the

displayed transducer.

CONTROL MODES

The CONTROL mode provides the user the means

to output a specific, highly regulated pressure. Two

different control modes are a standard feature of

the PCS 400. The two standard modes are identified

as NORM (for NORMAL), and RATE under the

LIMITS menu heading.

NORMAL Mode

NORMAL control mode is the default mode and is

indicated on the top line of the display by NORM.

This mode achieves stable pressure at the new

control point in the shortest time.

RATE Mode

RATE control mode is indicated by RATE on the

top line of the display, and should be selected when

overshoot must be kept to a minimum. RATE mode

provides a means to control the rate of change in

pressure units. This mode is useful where rapid

pressure changes would be harmful to sensitive

devices under test (DUTs). Overshoot in RATE

mode is typically less than in NORMAL mode, but

the time to achieve stable pressure will be longer

than in NORMAL mode. The minimum and maxi-

mum controllable rates of pressure change are

dependent on the FS range of the PCS 400 as shown

in the following table.

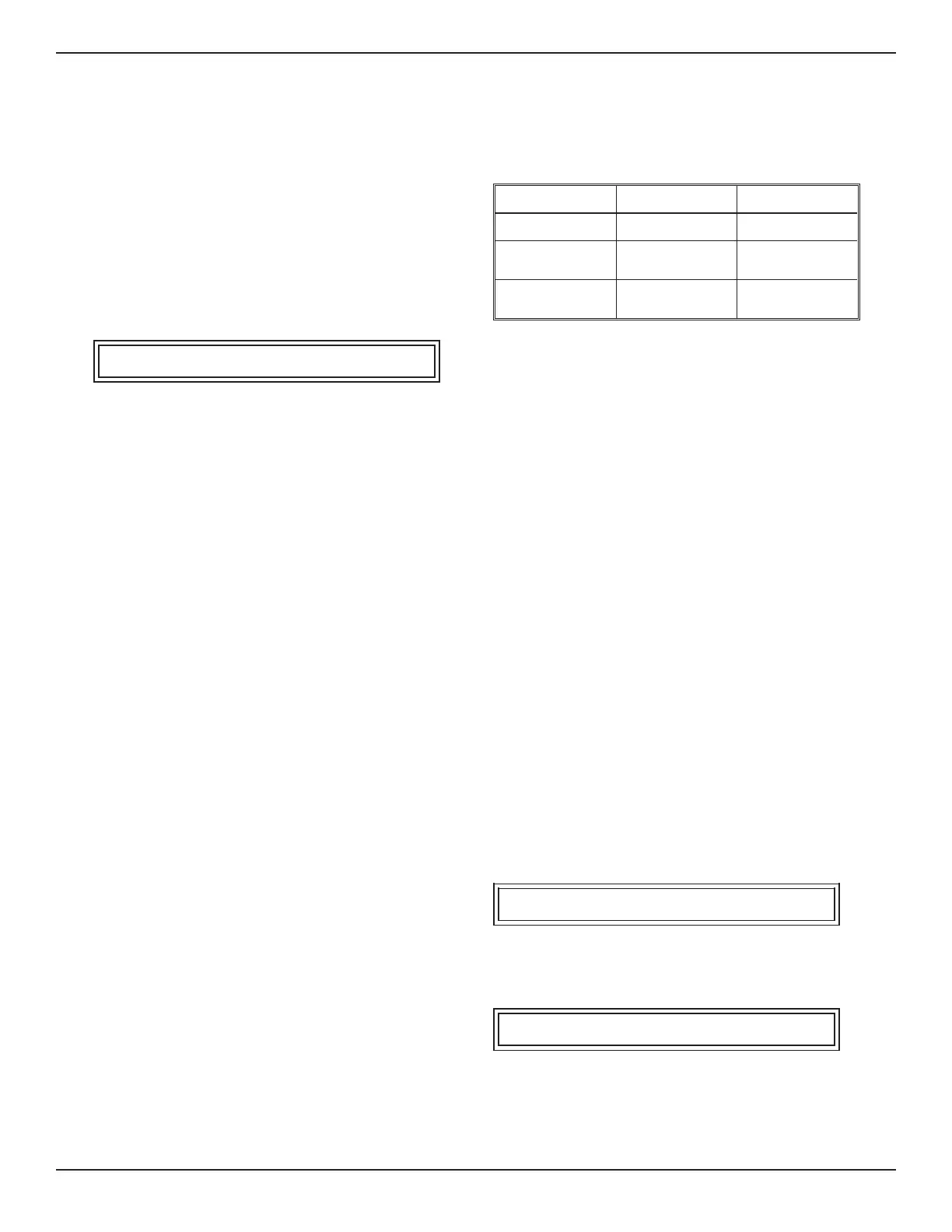

Table 3.2 – Min/Max Rate

Full Scale Minimum Maximum

£5 psi 0.00025 psi/sec 0.1 psi/sec

>5andupto

100 psi

0.0025 psi/sec 1 psi/sec

>100 and up to

1000 psi

0.025 psi/sec 10 psi/sec

The maximum pressure rates shown above are

based on external volumes of 0.5 liter, or less.

Larger volumes will reduce the maximum rate that

can actually be achieved. When a new control point

is entered the PCS 400 will attempt to control the

pressure change at the last rate value specified. As

the pressure approaches the control point the con-

trol rate of change will decrease to prevent over-

shoot at the commanded point. Because of this

automatic slow-down it may not be possible to

achieve the set rate between small pressure steps.

Note that when the [S] for pressure stable appears

in the display it indicates stability at the control

point rather than indicating a stable pressure rate.

Multiple Internal Transducers

For instruments with multiple internal

transducers, in CONTROL mode with

AUTORANGE on the PCS 400 automatically acti-

vates the lowest range transducer that can effec-

tively measure the commanded pressure. For

example, an instrument that has internal

transducers of 150 psi and 30 psi would automat-

ically switch to the 30 psi transducer when com-

manded to control at 10 psi. The address of the

active transducer (@ 01) is included on the second

line of the display as shown in the screen, below.

The [S] signifies that the controlled pressure is

stable at the measured value displayed.

CONTROL PRESS:(NORM)10.0000 PSI A

MEASURED @ 01: 10.0000 PSI A [S]

Likewise, if the control point is set to 31 psi while

in AUTORANGE the system will default to the 150

psi primary transducer and display as follows.

CONTROL PRESS:(NORM)31.000 PSI A

MEASURED: 31.000 PSI A [S]

Notice in particular the two differences; 1, the

transducer ID following MEASURED has disap-

peared; and 2, there is one less digit of resolution.

PCS 400 LOCAL OPERATION

www.mensor.com 3-9

Loading...

Loading...