3.3 Methods and Sequences

774 Oven Sample Processor, Instructions for use

33

3.3 Methods and Sequences

3.3.1 Designing a method

A method is made up of the following components:

• number of samples to be processed

• run sequences (start, sample and final sequences)

• Definition of the various instrument settings (report definitions, sample

changer settings, time-out settings, gas flow settings, dosing unit defini-

tions, manual stop options)

For details about instrument settings please refer to page 67ff.

Sequences

A sequence is a series of commands which are carried out in the defined

order when a series of samples is being processed. Functions for control-

ling the oven temperature, gas flow, lift and for moving the turntable are

available. External instruments (titrators, Coulometers, Dosimats, etc.) can

be controlled by efficient commands. In a sequence the further settings for

the individual instrument components and dosing units (700 Dosino or

685 Dosimat) can also be defined or altered.

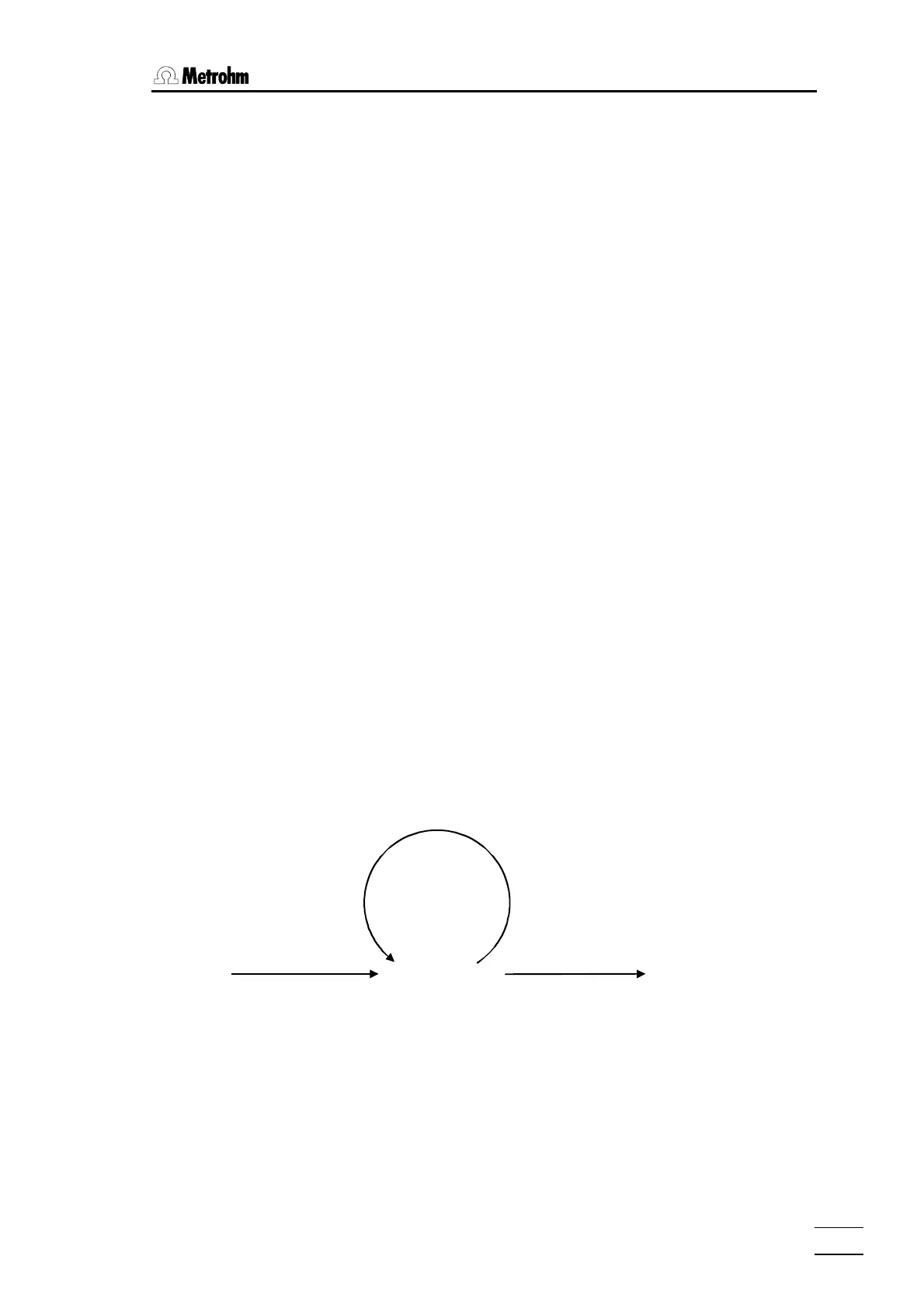

Processing a sample series is carried out in three phases. These are:

Start sequence: Command sequence which is carried out once at

the start of the series.

Sample sequence: Command sequence which is carried out for

each sample.

Final sequence: Command sequence which is carried out once at

the end of the series.

sample sequence

start sequence final sequence

<START>

number

of samples

normal state

Course of a method

Loading...

Loading...