4.3 KF Moisture determination

774 Oven Sample Processor, Instructions for use

41

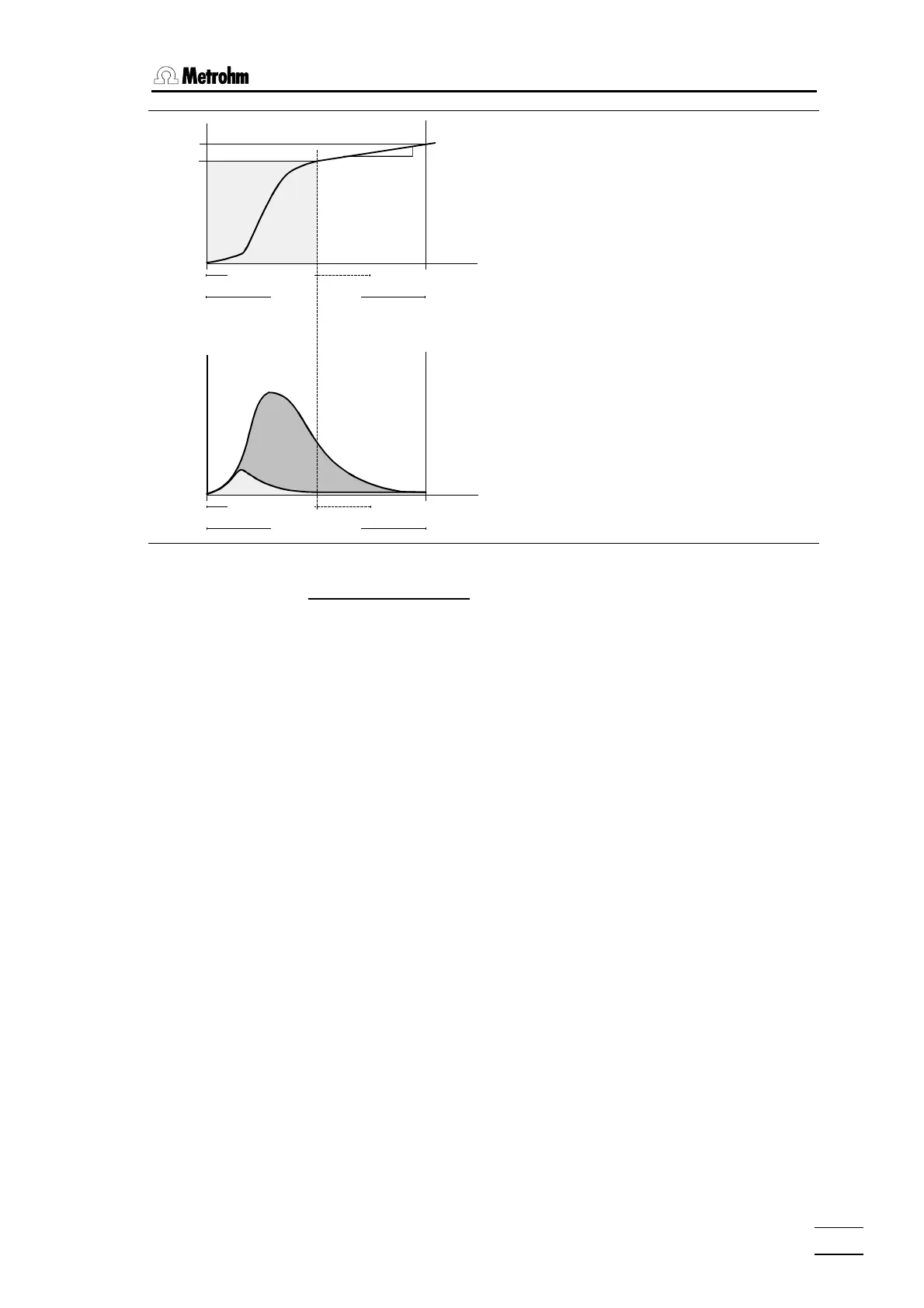

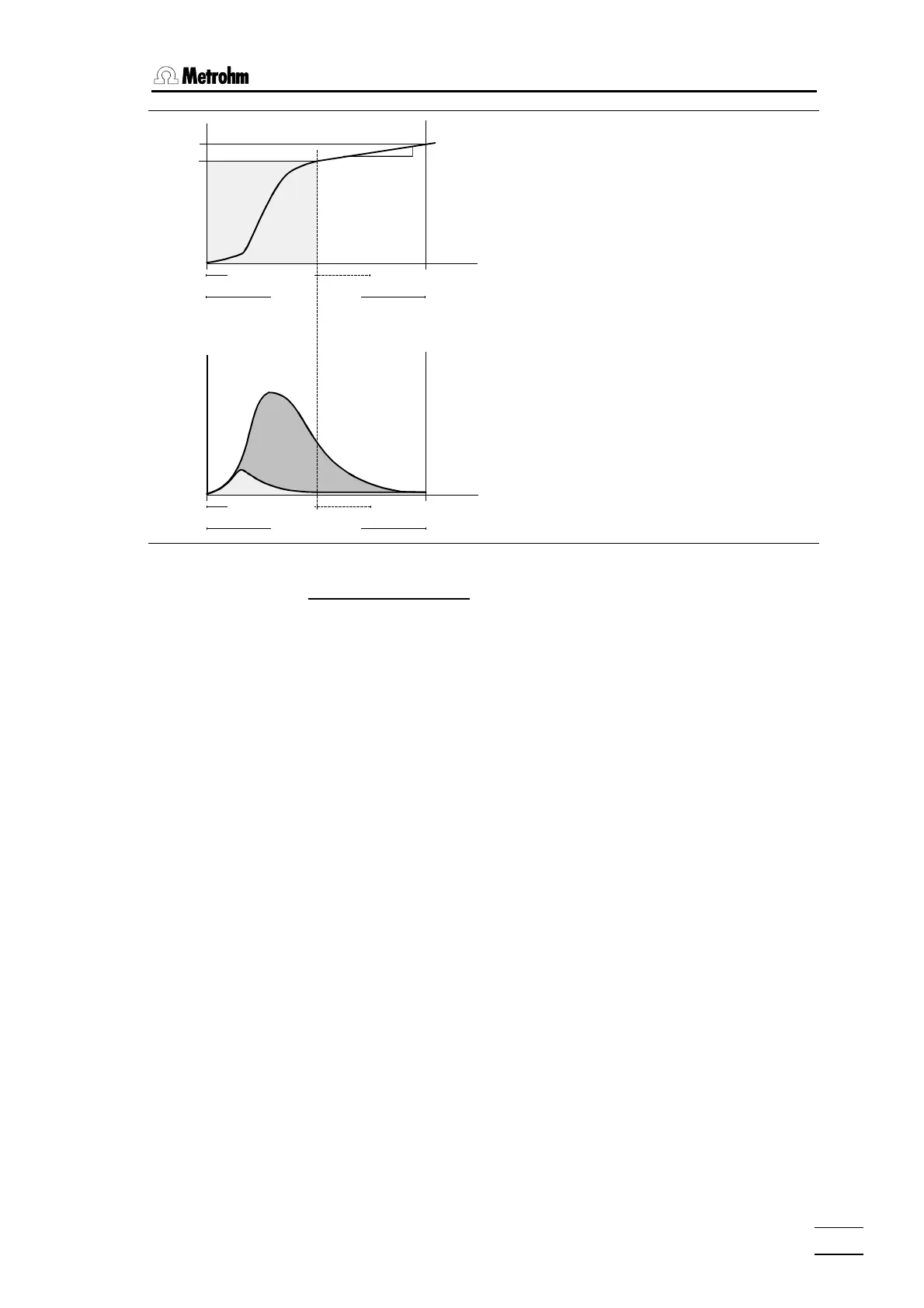

water

[

µ

g]

t [min]

vial humidity

in

µ

g

system drift

in

µ

g/min

determination interval

total blank value

drift

[µg H

2O/min]

t [min]

min. extraction time

blank

sample

min. extraction time

determination interval

The blank value is made up of the moisture

which adheres to the sample vial * and a sys-

tem drift which is latently present and whose

cause can be found in a minimal residual mois-

ture in the carrier gas and possibly leaks in the

tubing system.

*

The use of pre-dried sample vials has no significant advan-

tages. On the contrary, this causes the reproducibility of

the results to be adversely affected.

The accompanying diagram shows the theoreti-

cal course of a sample determination with the

774 Oven Sample Processor. It is clear that, in

order to determine the amount of water correctly

(dark gray area), the blank value must be sub-

tracted from the total amount of moisture deter-

mined.

Sample determination

• When the reaction medium has been conditioned fully the gas flow is in-

terrupted, the sample moved to the oven and introduced into the oven

block with the help of the penetration needle.

• The gas flow is switched on again and the sample determination started

at the Coulometer or KF Titrator. Definition of an extraction time ensures

that a minimum determination time and therefore heating period will be

observed.

• The driven-off moisture is now transported to the reaction vessel by the

stream of gas. The transfer tube heating ensures that no moisture can

condense in the tubing.

• When the determination is finished the moisture content of the sample is

calculated taking the previously determined blank value into considera-

tion.

• The gas flow is switched off again and the conditioning vessel again

move to the oven.

• When the needle has penetrated the conditioning vessel septum the gas

flow is switched on again and the reaction medium is conditioned.

• When conditioning has been carried out the next sample can be deter-

mined, see above.

Care must be taken that the septa are still airtight after penetration by the

hollow needle and that no moisture can escape. The septum of the condi-

tioning vessel is particularly at risk as it is penetrated many times during the

sample series.

Loading...

Loading...