OM-272384 Page 18

5-2. Controls For Millermatic 211 Auto-Set

™

Models

OM-272 384 Page 5

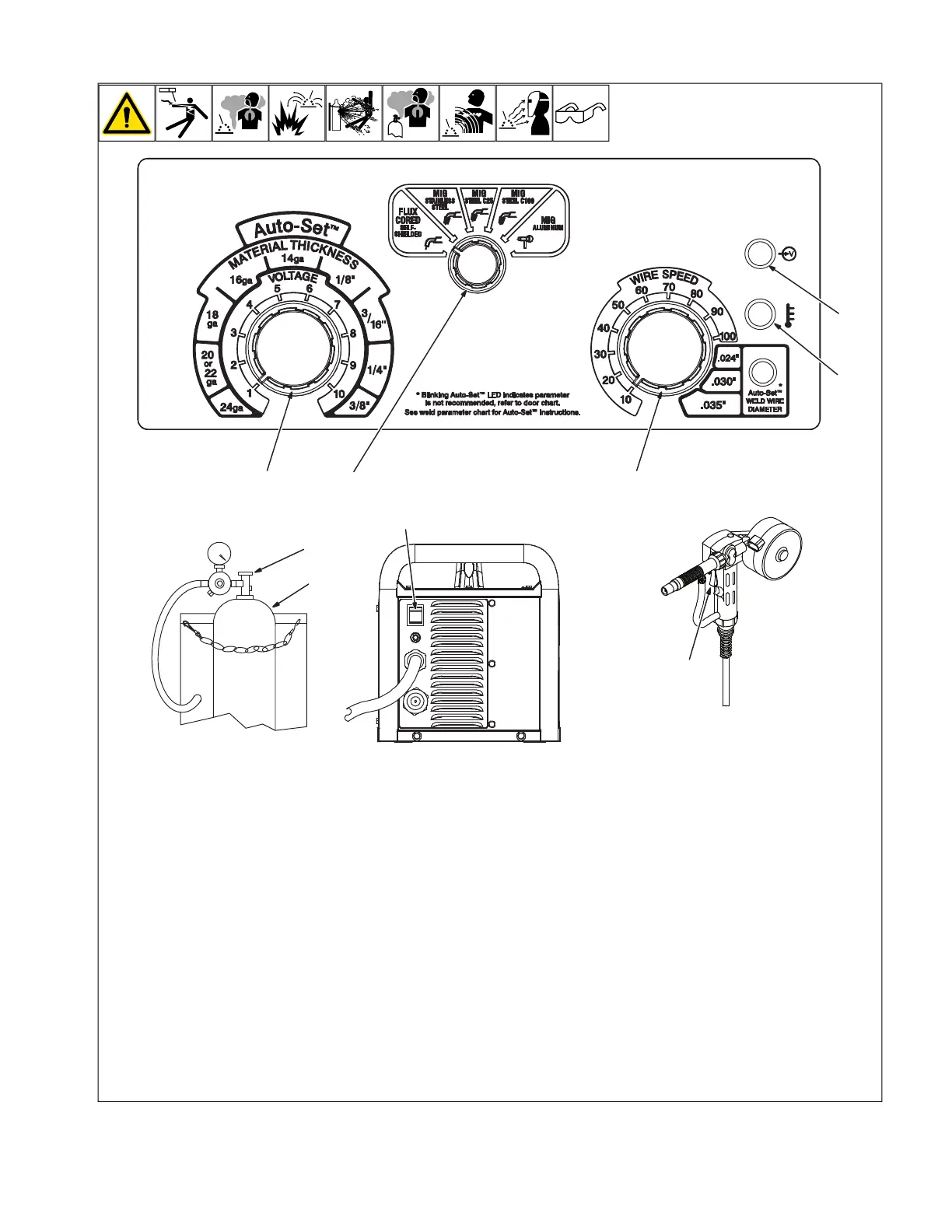

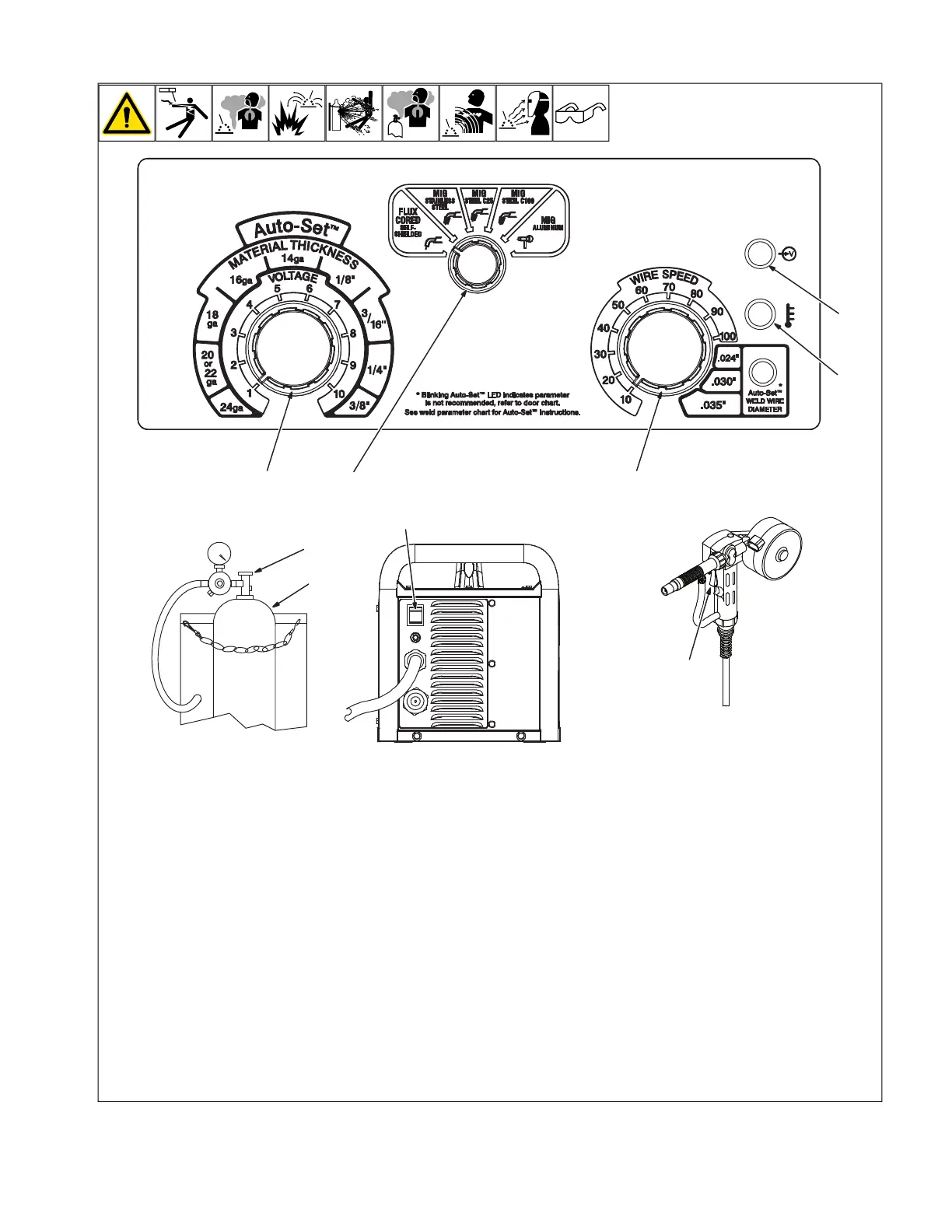

2-2. Controls For Millermatic 211 Auto-Set Models

274604-A / 270208-A

Rear View

6

1

2

4

3

3

7

8

9

10

1 Shielding Gas Cylinder

For shielding gas connections, see welding

power source Owner’s Manual.

2 Valve

Open valve on cylinder just before welding

Close valve on cylinder when finished

welding.

3 Voltage/Material Thickness Control

Turn control clockwise inside white scale (1-

10) to increase voltage (see weld parameter

chart in welding power source).

4 Process Select Control

Turn control to select desired weld process.

5 Perform Motor Calibration

See the Millermatic 211 Owner’s Manual for

Spoolmate Motor Calibration procedure.

6 Wire Speed/Wire Diameter Control

Turn control clockwise inside white scale

(10-100) to increase wire feed speed. (see

weld parameter chart in welding power

source).

7 Over Temperature Light

If unit overheats, light turns on and output

stops. Allow unit to cool before resuming

operation. This light will also communicate

additional unit errors.

8 Power Light

Power light illuminates when the unit is

turned on and powered up.

9 Power Switch

Use switch to turn unit On or Off.

10 Trigger

Press trigger to energize welding power

source contactor, start shielding gas flow,

and begin wire feed.

Loading...

Loading...