— 2.37 —

CHECKING CUTTING CONDITIONS [TEST CUT]

Whenever you have changed cutting conditions or the tool(s) to be used, execute the “test cut”

function to check the following items. Refer to “Checking the status of tools” (see page 2.37).

(1) Whether or not the cutting (plotting) conditions are proper

Whether or not a work is properly cut or the finished plot has thin spots

(2) Whether or not the tool is off-center

If the tool is off-center, inaccuracy in cutting will result.

(3) Whether or not the tools are matched to each other

If the plot is cut with a tangential cutter, check whether or not the cut pattern exactly matches

the plot.

For the above-stated case (1), re-establish the cutting conditions. (See page 2.28.)

For the above-stated cases (2) or (3), correct the trouble through the “adjustment of the tools.” (See

page 3.5.)

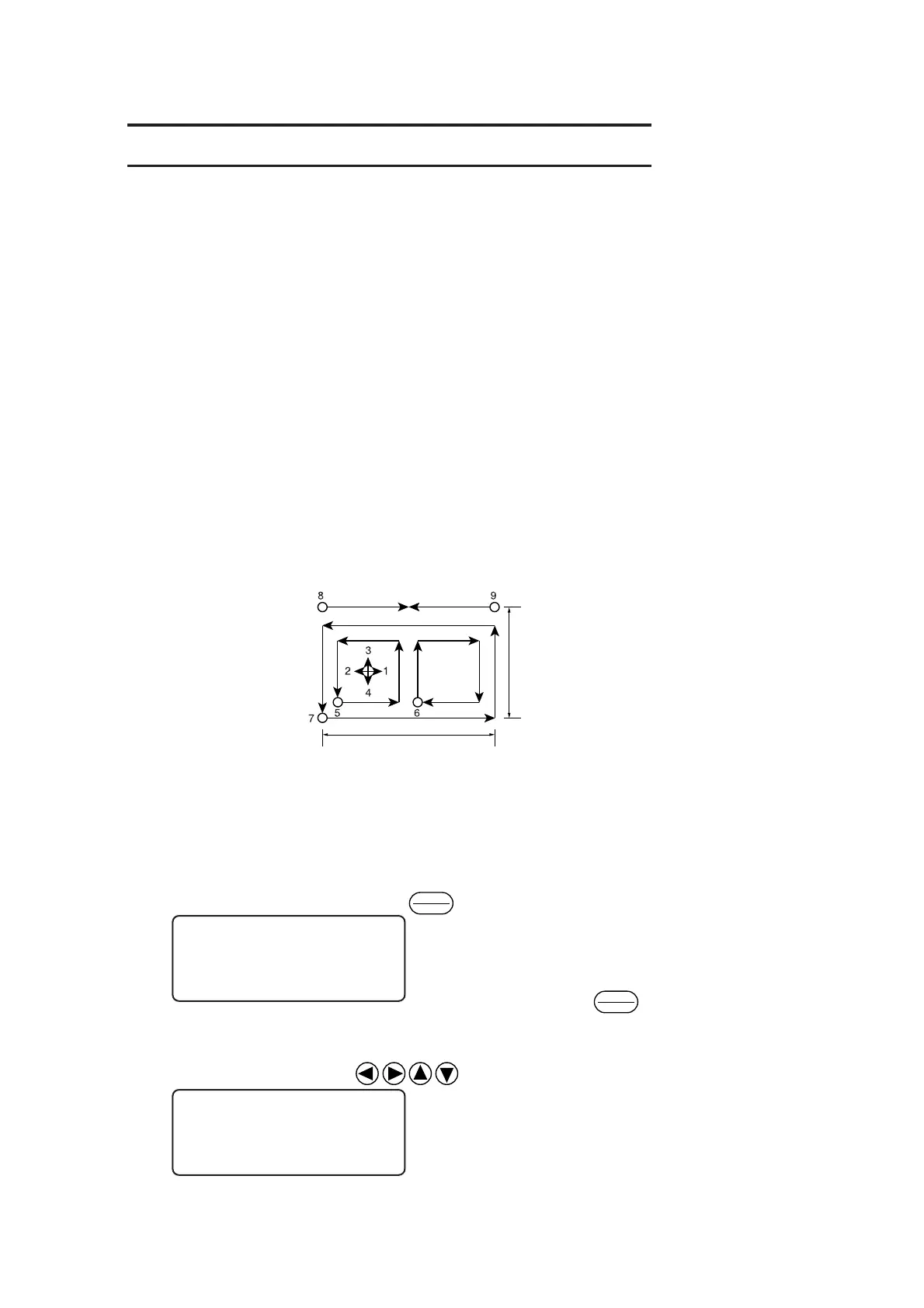

The pattern for the test cut and the cutting (plotting) order is as follows:

Ο : Start point

→ : Direction of cutting

27.5 mm

15 mm

1 Select a tool to be used for test cut us-

ing the [TOOL SELECT] function.

Call up the first page of the LOCAL

menu to the screen. See page 2.26.

2 Invoke the LOCAL menu on the

screen.

If the device is in the REMOTE mode,

press the

REMOTE

LOCAL

key to select the LO-

CAL mode.

1 Move the head to a position where test

cut is to be performed.

Press the jog keys to move the head.

[ LOCAL ] 1 / 4

TOOL SELECT ———>

CONDITION ———>

TEST CUT ———>

< MOVE > [ mm ]

00.00 00.00

SPEED FAST >

PEN UP >

REMOTE

LOCAL

Loading...

Loading...