5-1

5 Testing and Maintenance

5.1 Introduction

To ensure the monitor always functions normally, qualified service personnel should perform regular inspection,

maintenance and test. This chapter provides a checklist of the testing procedures for the monitor with recommended

test equipment and periodic maintenance schedule. The service personnel should perform the testing and

maintenance procedures as required and use appropriate test equipment.

The testing procedures provided in this chapter are intended to verify that the monitor meets the performance

specifications. If the monitor or a module fails to perform as specified in any test, repairs or replacements must be

done to correct the problem. If you have any question, contact Mindray Technical Support Department.

CAUTION

All tests should be performed by qualified service personnel only.

Care should be taken to change the settings in [User Maintenance] and [Factory Maintenance] menus to

avoid loss of data.

Service personnel should acquaint themselves with the test tools and make sure that test tools and cables

are applicable.

5.2 Preventative Maintenance

Preventative maintenance refers specifically to actions taken to prevent inaccurate results in the eqipment. The

following sections provide a list of recommended preventative maintenance procedures and their recommended

frequencies.

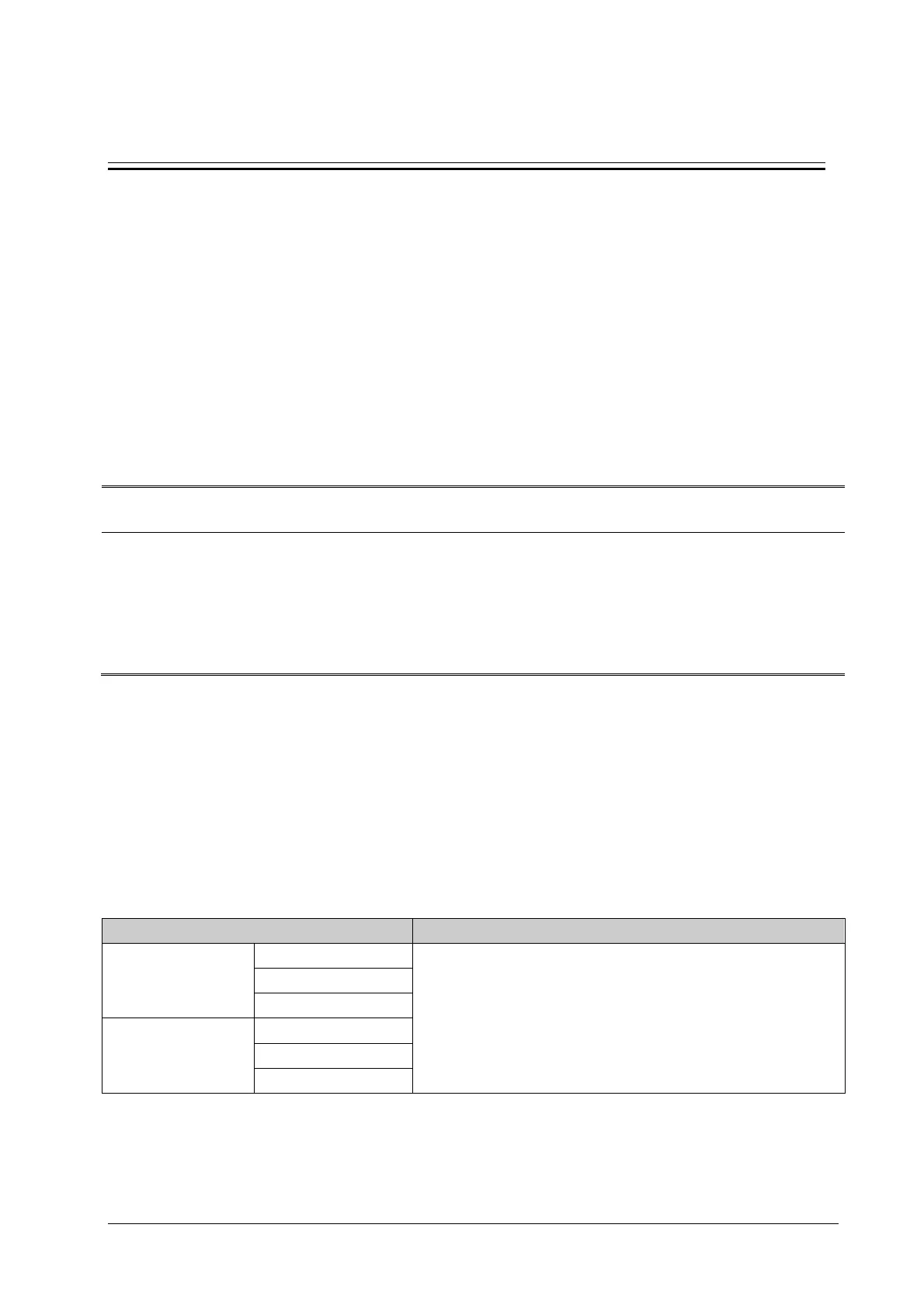

5.2.1 Preventative Maintenance Frequency

Check/Maintenance Item Frequency

CO

2

tests and

calibration

Leakage test 1. If the user suspects that the measurement is incorrect.

2. Following any repairs or replacement of relevant module.

3. Once a year.

Performance test

Calibration

AG test

Leakage test

Performance test

Calibration

Loading...

Loading...