6-532 Interference avoidance function

5Functions set with parameters

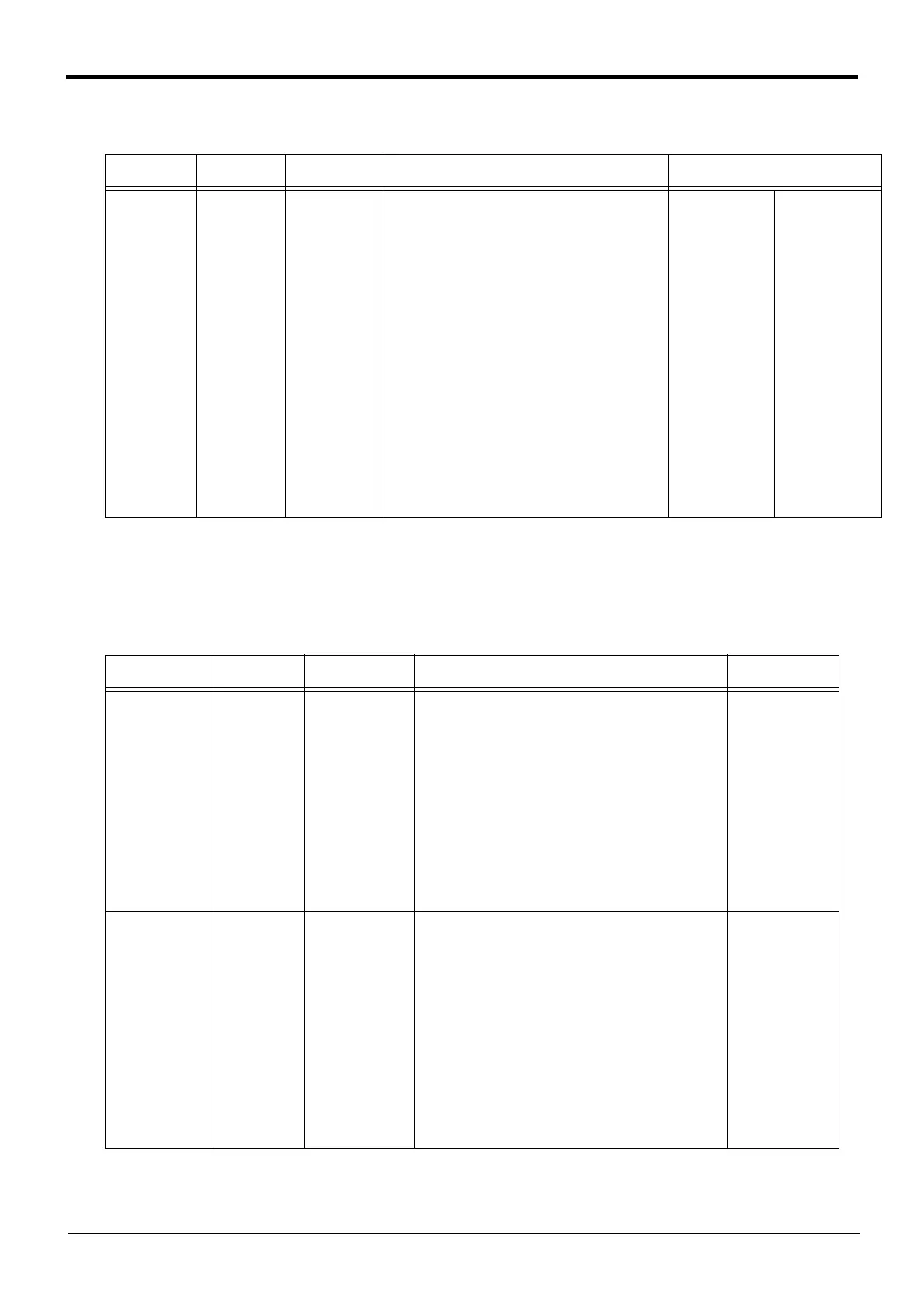

<4>Simulated component enable/disable: CAVSCA1 to 8

Table 5-34:Simulated component setting parameter (Robot arm: CAVSCA1 to 8)

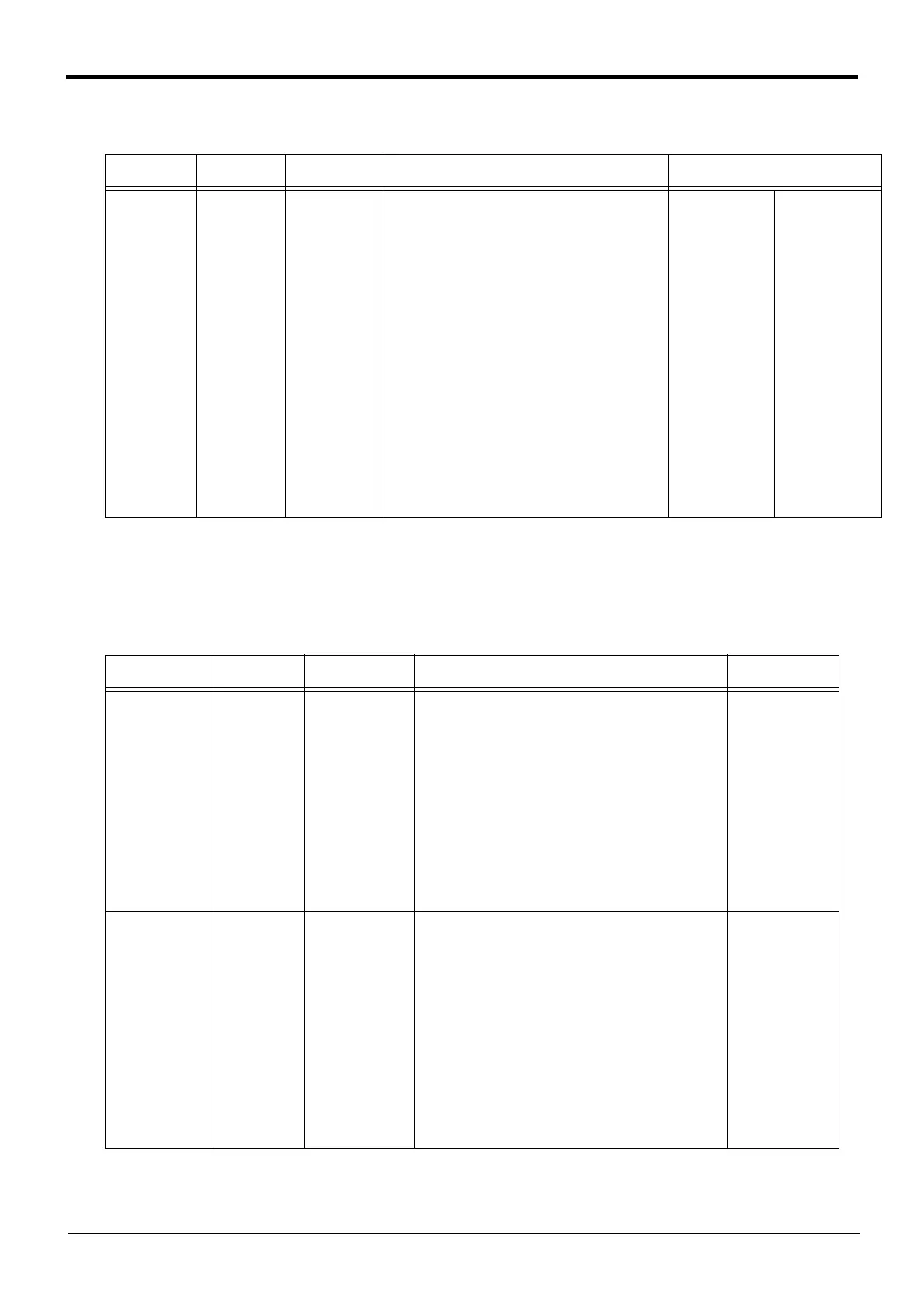

2) Simulated components for hand

The parameters required to register a simulated hand are shown in Table 5-35.

Table 5-35:Simulated component setting parameters (hand)

Parameter

Parameter

name

No. of arrays

No. of characters

Details explanation Factory setting

Simulated

component

enable/disable

(robot arm)

CAVSCA1 to 8 Integer 3 Set whether to check (enable or disable)

interference for each simulated component. (Each

simulated component corresponds to the last digit

(1 to 8) of the parameter name.)

1st element: Enable/disable the setting

(0: Disable, 1: Enable)

2nd element: Set whether to let the interference

avoidance function to temporarily

disable interference checks during

jog operation. (Refer to Temporarily

canceling the interference avoidance

function.)

(0: Disable, 1: Maintain enabled

state)

Note) If interference is inevitable

during jog operation for

teaching, setting the simulated

hand or workpiece to “0:

Disable” can be convenient.

3rd element: Fixed to 0

RH-3/6/12/20FH

series:

CAVSCA1=1, 0, 0

CAVSCA2=0, 0, 0

CAVSCA3=1, 0, 0

CAVSCA4=1, 0, 0

CAVSCA5=1, 0, 0

CAVSCA6=1, 0, 0

CAVSCA7=1, 0, 0

CAVSCA8=1, 0, 0

RH-3FHR series

CAVSCA1=1, 0, 0

CAVSCA2=1, 0, 0

CAVSCA3=1, 0, 0

CAVSCA4=1, 0, 0

CAVSCA5=1, 0, 0

CAVSCA6=1, 0, 0

CAVSCA7=0, 0, 0

CAVSCA8=0, 0, 0

RV-F series:

CAVSCA1=1, 0, 0

CAVSCA2=1, 0, 0

CAVSCA3=1, 0, 0

CAVSCA4=1, 0, 0

CAVSCA5=1, 0, 0

CAVSCA6=0, 0, 0

CAVSCA7=0, 0, 0

CAVSCA8=0, 0, 0

Parameter

Parameter

name

No. of arrays

No. of characters

Details explanation Factory setting

Hand number and

shape

(hand)

CAVKDH1 to 8 Integer 2 Set the hand number and shape of a simulated hand to

be registered. Up to eight simulated hand types can be

registered. (Each type corresponds to the last digit (1 to

8) of the parameter name.)

1st element: Hand number

Corresponds to the hand condition number

for changing the simulated component with

the Loadset (Load Set) command.

0: Simulated component type set as default.

1 to 8: Hand condition number designated with the

Loadset (Load Set) command

2nd element: Shape

0: a sphere

1: a cylinder

Set all parameters

(CAVKDH1 to 8) to

“0, 0”.

Center position of

simulated compo-

nent

(hand)

CAVPSH1 to 8 Real number 6 For each simulated component, designate the center

position and pose of the simulated component from the

origin point of the Mechanical interface coordinate

system. (Each simulated component corresponds to the

last digit (1 to 8) of the parameter name.)

1st element: Distance in X axis direction (mm)

2nd element: Distance in Y axis direction (mm)

3rd element: Distance in Z axis direction (mm)

4th element: angle of rotation on X axis (degree)

5th element: angle of rotation on Y axis (degree)

6th element: angle of rotation on Z axis (degree)

Note) Calculate the rotation angle in order of Z → Y → X

axis. If shape is the sphere, setting of the rotation

angle is unnecessary.

Set all parameters

(CAVPSH1 to 8) to

“0, 0, 0, 0, 0, 0”.

Loading...

Loading...