4G1 ENGINE (E-W) -

Crankshaft and Cylinder Block

11A-12-4

PWEE9520

E

Nov. 1995Mitsubishi Motors Corporation

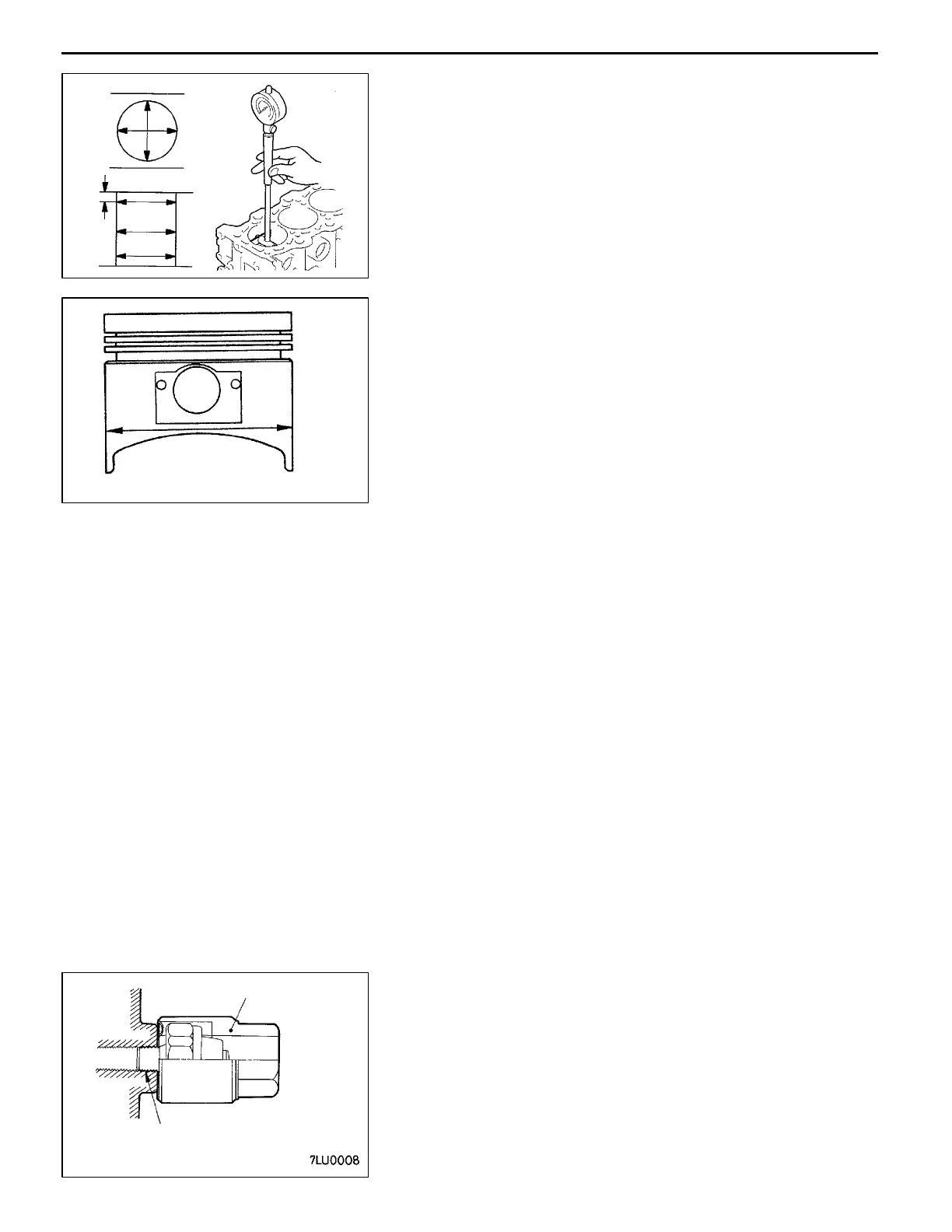

(4) Using a cylinder gauge, measure each cylinder’s bore

and cylindricity. If any cylinder is severely worn, bore

all the cylinders to oversize and replace the piston and

piston rings accordingly. Take measurements at th e points

shown.

Standard value:

Cylinder bore:

4G13 engine: 71.0 mm

4G15 engine: 75.5 mm

4G18 engine: 76.0 mm

Cylindricity: 0.01 mm or less

3. BORING CYLINDERS

(1) Oversize pistons to be used should be determined on

the basis of t he cylinder with the largest bore.

(2) Oversize pistons are available with t he following oversize

dimensions: 0.25 mm, 0.50 mm, and 1.00 mm. Measure

the diameter of the piston to be used. Boring must be

carried out such that the piston-to-cylinder clearance

complies with the standard value. The piston’s diameter

should be measured at the points shown.

(3) Calculate the boring finish dimension based on the piston

diameter dimension.

D

[Boring finish dimension] = [piston O.D.] +

[piston-to-cylinder clearance (0.02 – 0.04 mm)] -

[honing margin (0.02 mm)]

(4) Bore each cylinder to the calculated boring finish

dimension.

Caution

To prevent distortion caused by heat increases during

boring bore the cylinders in the following order: No.

2, No. 4, No. 1, No. 3.

(5) Hone the cylinders to the final finish dimension (piston

O. D. + piston-to-cylinder clearance).

(6) Check the clearance between the pistons and cylinders.

Standard value: 0.02 - 0.04 mm

INSTALLATION SERVICE POINTS

"

A

A

OIL PRESSURE SWITCH INSTALLATION

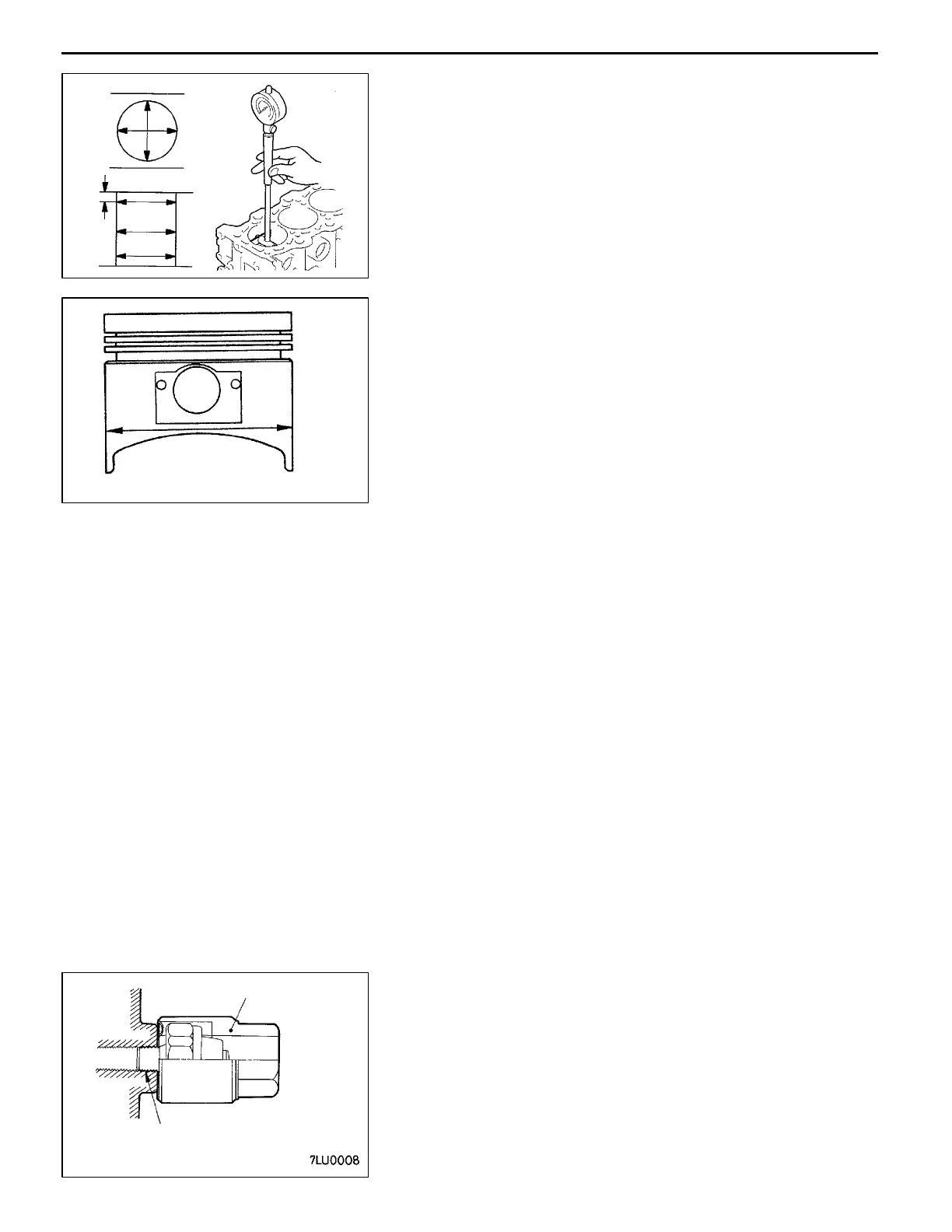

(1) Apply the specified sealant to the thread, then fit the

oil pressure switch using the special tool shown in t he

illustration.

Specified sealant:

3M ATD Part No. 8660 or equivalent

Caution

1. Apply sealant such that none is squeezed out

past end of the thread.

2. Do not over-tighten the oil pressure switch.

PWEE9520-A

E

Dec. 1998Mitsubishi Motors Corporation Revised

12

mm

6EN0553

Piston O. D.

Thrust

direction

6EN0554

Apply sealant

MD9988054

Loading...

Loading...