_

OK

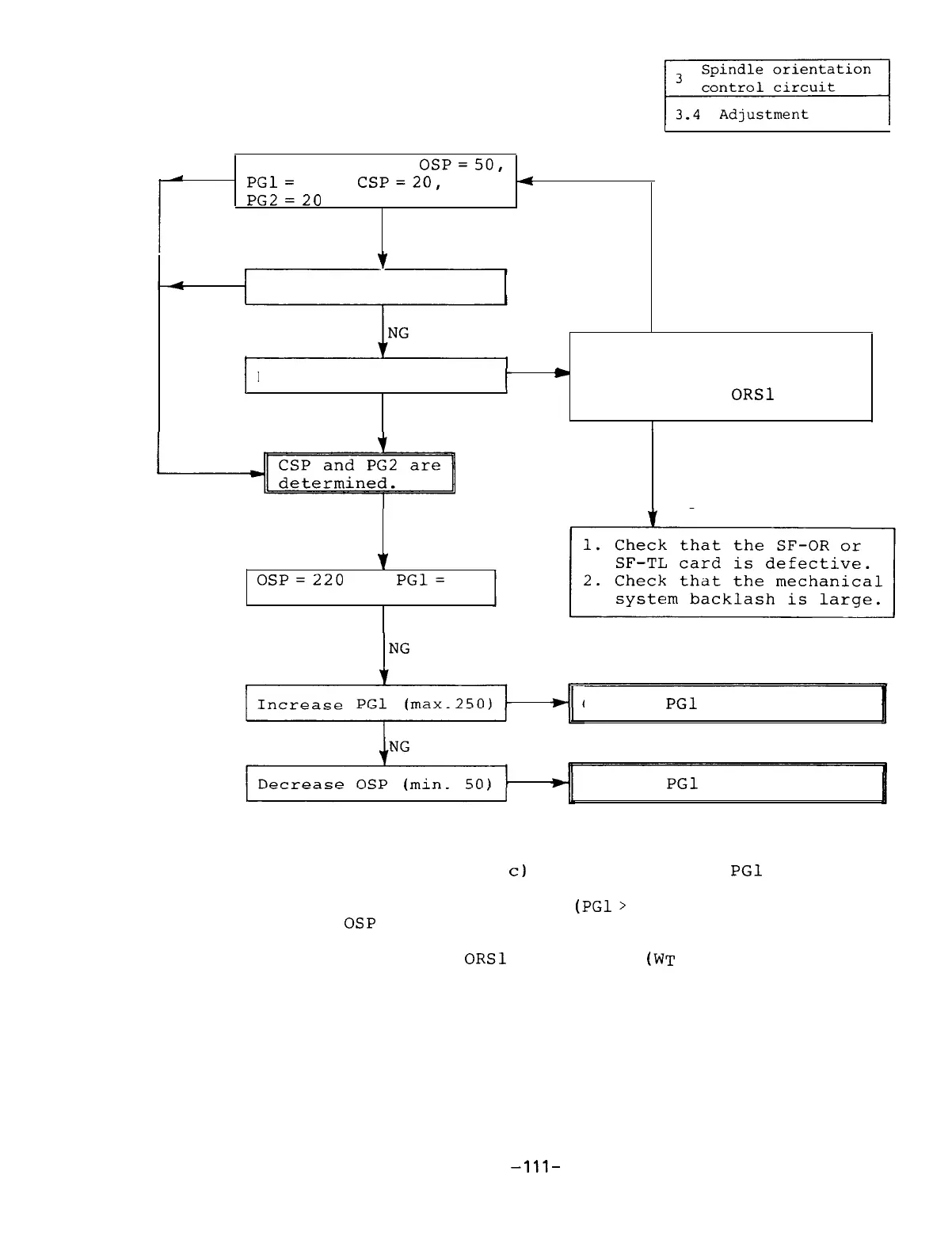

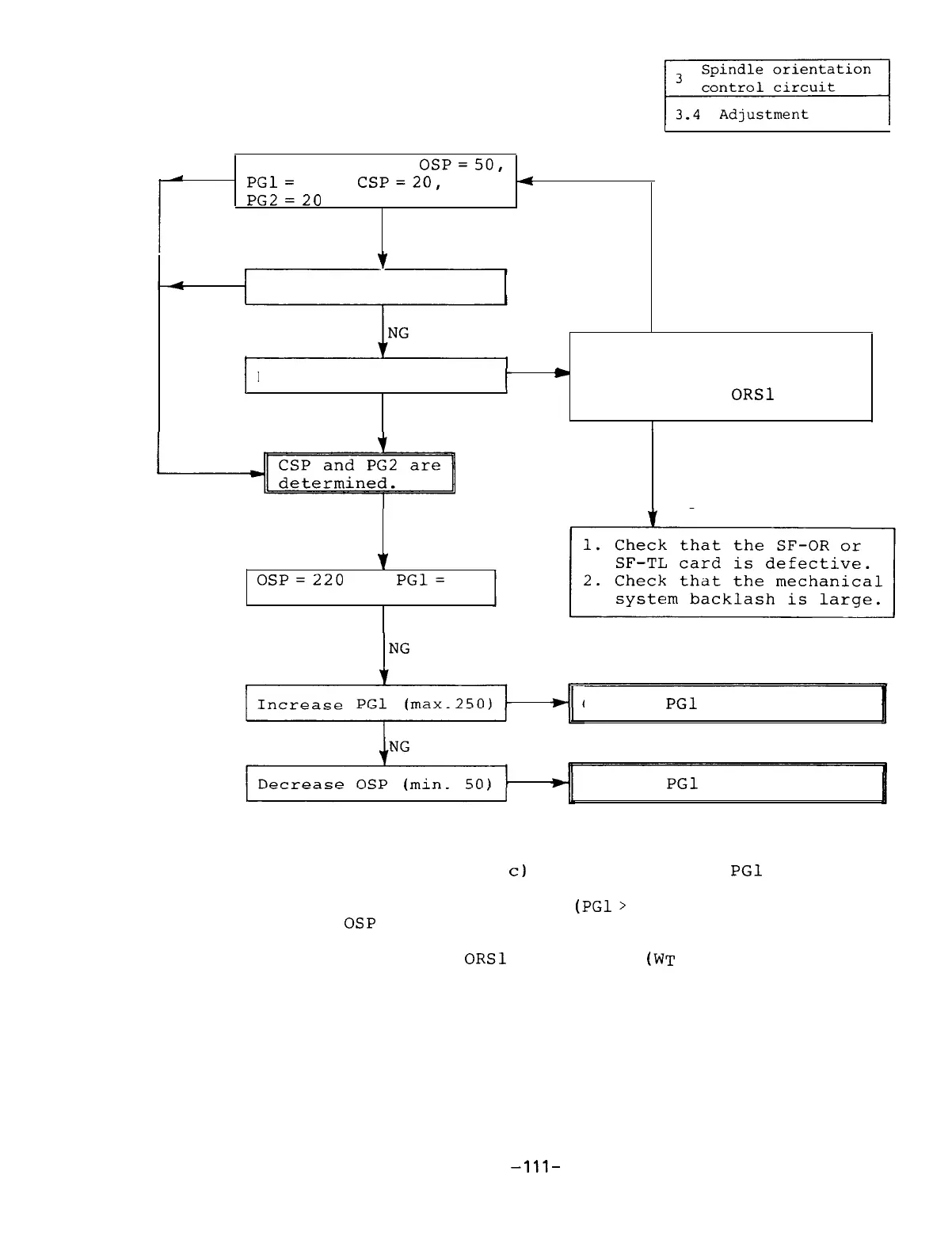

Set as follows:

OSP=SO,

PGl=

200,

CSP=20,

and

4

PG2=20

NG (The motor over-

runs when it stops.)

OK

The spiondle does not

Increase PG2 (max. 40)

vibrate when it stops.

Increase bits 8 to B (Kp

NG

magnification) and bit C

Decrease CSP

(min.

10)

*

to F (Ki magnification) of

the parameter ORSl in the

same ratio.

OK

I

Ill

Without increasing

Kp and Ki, the spin-

dle vibrates when it

stops.

Next step

'I

OSP=220

and

PGl=

180

are determined.

OK

OSP and

PGl

are determined.

OK

OSP and

PGl

are determined.

(Note) 1.

2.

When the orientation time becomes long because the

time period on which the spindle rotates at a creep

speed (point b to

c)

is long, decrease

PGl

or in-

crease OSP in the manner that the spindle does not

overrun when it stops.

(PGl>

PG2,

the maximum value

of

OSP

= 300.)

The parameter

ORSl

bits 0 to 3

(WT

selection) are

the compensation gain for delay/advance of bit 4

(control method in servo lock situation).

Increase WT and the temporary servo rigidity in-

creases and the torque against the position devia-

tion decreases.

-lll-

Loading...

Loading...