1 Troubleshooting

1.3.4

The motor does not rotate.

Item

Cause Check

Remedy

Trouble analysis

0

When a rotation command is

o

Review the cause and take a

issued,

an alarm is indicated

proper action by referencing

on the display on the spindle

Section 1.3.3.

amplifier printed circuit

1

board (SF-CA card).

D

When no alarm occurs:

0

Go to the Item 2 or later.

The control signal cable

o

Check that the cables are

0

Correctly connect them.

or power cable is

in-

correctly connected and

2

correctly connected or

they are not broken.

D

Replace the broken cable

is broken.

with a new one.

The input power voltage

o

Measure the voltages at the

D

Improve the power condition

is abnormal.

input terminals Xl, X2, and so that the input power

3

X3 of the amplifier using a voltage is in the allowable

circuit tester.

range.

(See Table 1.3.)

The control power supply

D

Measure all the DC output

o

Replace the control power

4

(SF-PW module) is

defec-

voltages of the SF-PW module

supply (SF-PW module) with

tive.

using a circuit tester.

a new one.

(See Appendix

6(4).)

(See Section 2.4.1.)

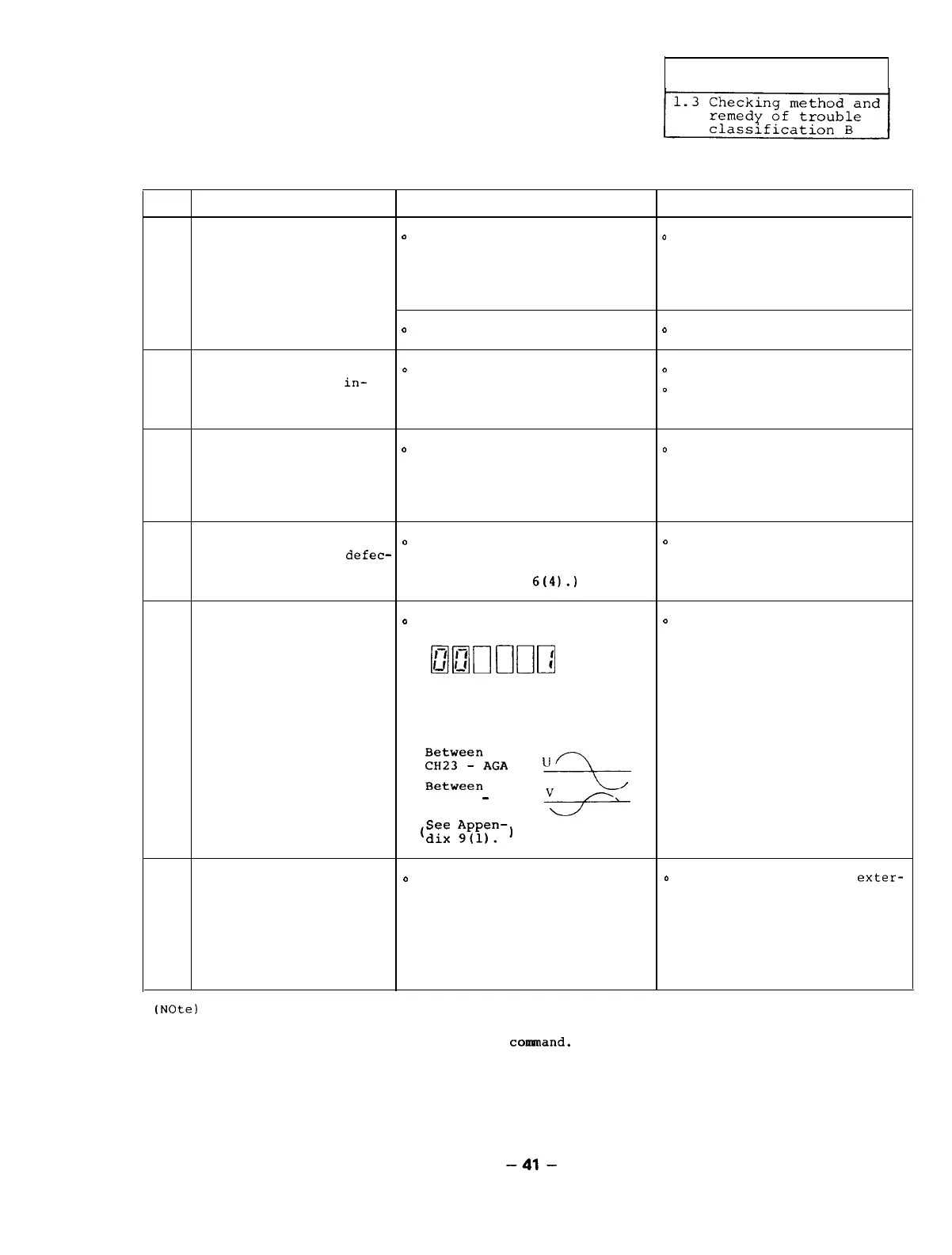

The printed circuit

o

Set the amplifier parameterer

o

Replace the printed circuit

board SF-CA card is as follows,

input a reference

board SF-CA card with a new

defective.

amnrrnn

(Note)

one.

(See Section 2.4.4.)

speed in the open loop state

to cause the motor to rotate,

and check that a reference

sine wave occurs on the

5

oscilloscope.

l%z;:%AGA

U-L

CH14

-

AGA

e

(See

Appen-)

dix

9(l).

The external emergency

o

Check that the bit 2

0

Correctly connect the

exter-

stop signal or reset

(emergency stop) of the

nal signal cable.

signal is input.

external signal is turned on

6

or the portion between CON1

pins No.47 and No.48 (emer-

gency stop) or portion bet-

ween pins No.19 and No.20

(alarm reset) is turned on.

(Note)

The parameter 00 becomes valid just after it is set to 1. Since the parameter is

cleared when the power is turned off or the equipment is reset, just after 1 is set,

input the speed reference and start

coannand.

-41-

Loading...

Loading...