4.2 Checking operation

1) Check the operation of the spindle at a low speed.

Example: G84

ZlO,

Fl,

0

S50

2) The spindle speed should be 50 rpm.

Check that it

rotates for 10 turns until it comes to the hole bottom

and returns to the start position.

3) When the spindle normally rotates, perform a cutting

work using a floating tapper.

4) When the floating tapper works correctly without expan-

sion and contraction of the tapper, perform a cutting

work using a tool which contains the floating tapper.

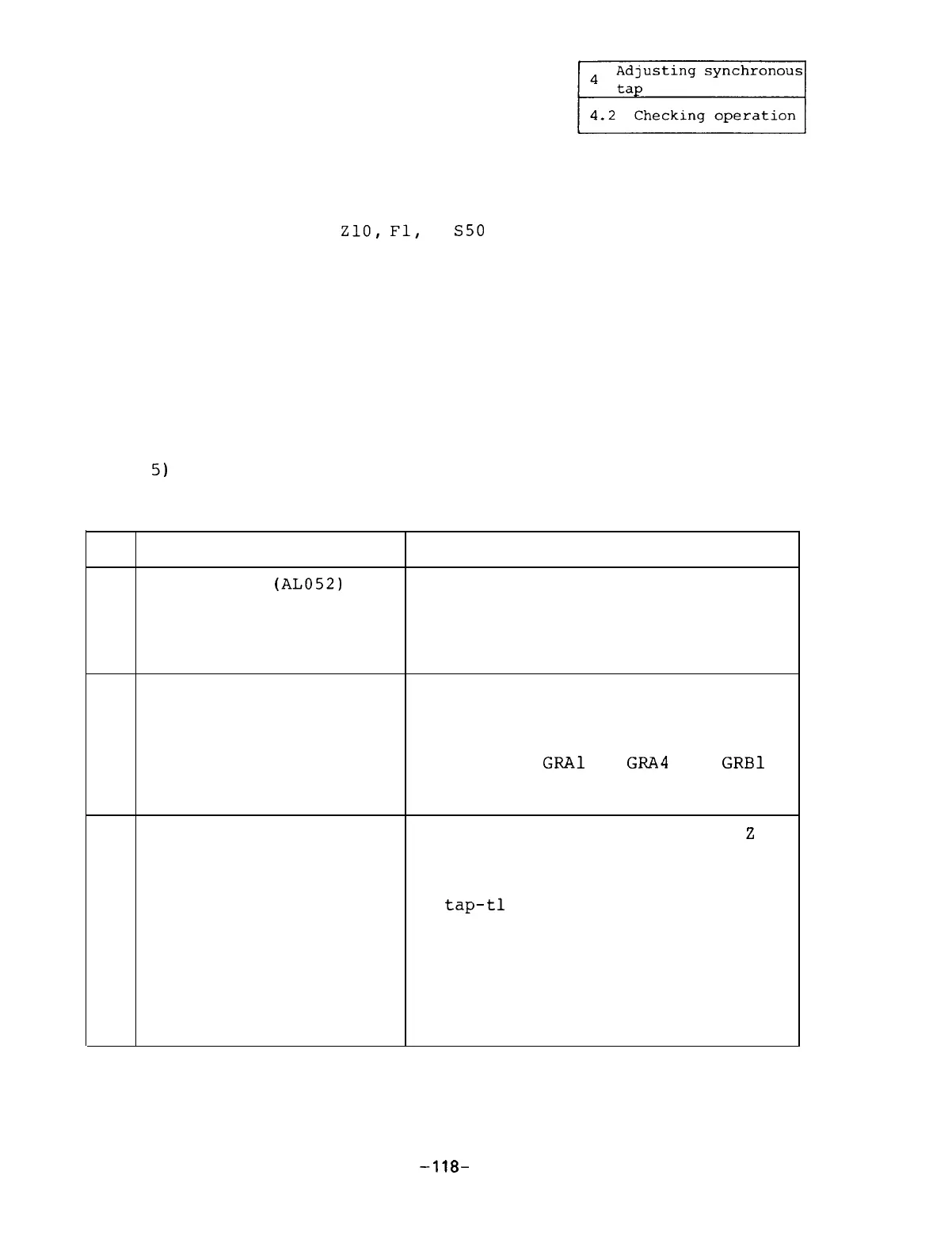

5)

If there is a defect,

take proper countermeasures in

accordance with the following table.

No.

Phenomenon

Remedy

Over droop

(AL0521

1) The position loop detection

occurs.

direction of spindle parameter

1

0RS2 bit E is reversed.

2) The fundamental specification

(tap tl) is too short.

The spindle rotating

1) The setting of close/semi-close

traveling amount does

of spindle parameter ORS2 bit

not conform with that

A is incorrect.

2

being specified.

2) The spindle parameter gear ratio

settings

GRAl

to

GRA4

and

GRBl

to GRB4 are incorrect (in the

semi-close state).

The tap is broken.

1) The axis specification axis

2

The tapping accuracy is tap-g and the spindle parameter

bad.

PGC are incorrect.

2) The fundamental specification

tap-t1

is short.

3

3) The screw pitch F of the program

differs from the real screw

pitch.

4) The tap slips at the chuck.

Replace the existing chuck with

an other one whose tightening

torque is large.

Continued on the next page.

-118-

Loading...

Loading...