1. FUNCTIONS AND CONFIGURATION

1 - 14

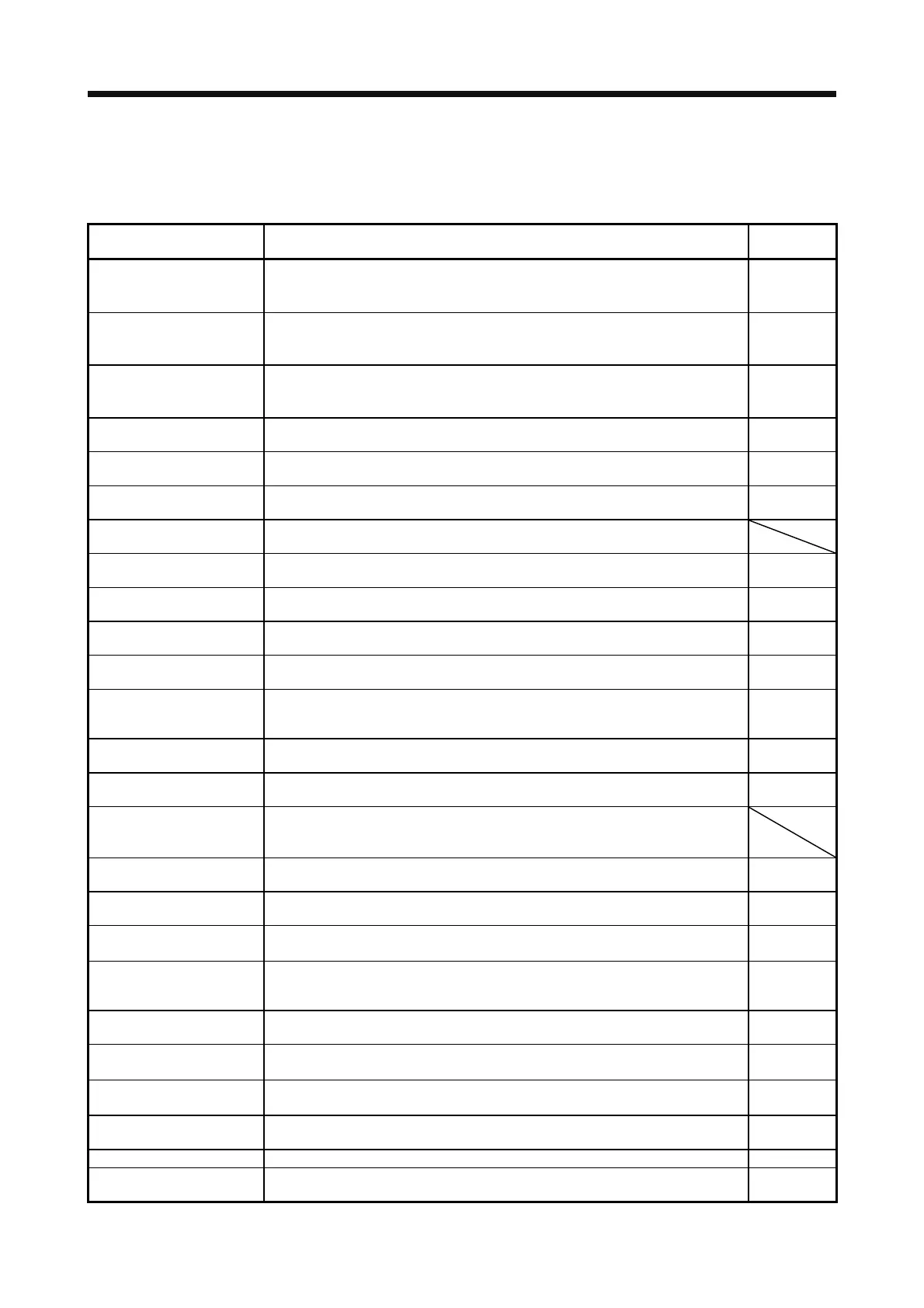

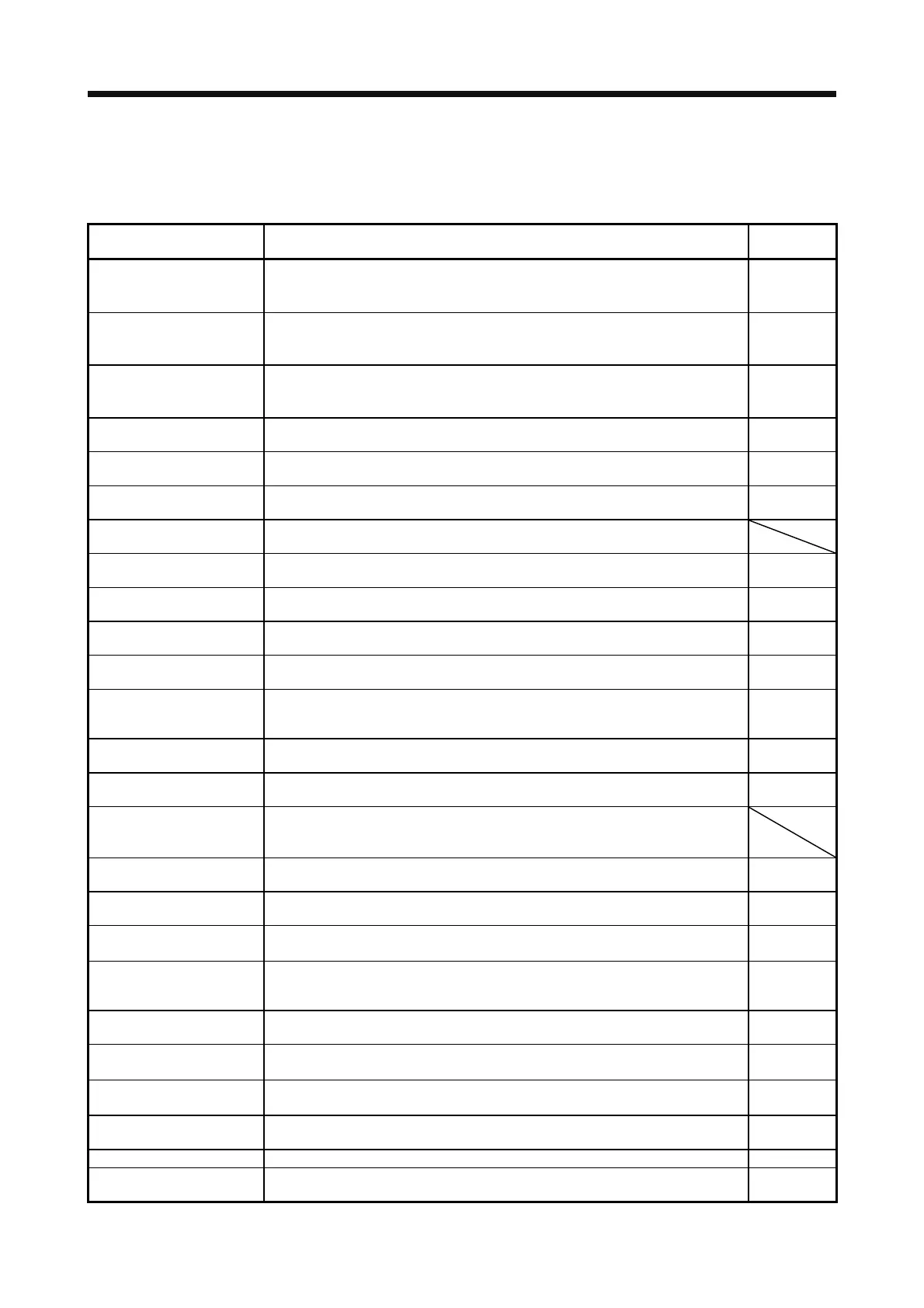

1.5 Function list

The following table lists the functions of this servo. For details of the functions, refer to each section

indicated in the detailed explanation field.

Function Description

Detailed

explanation

Position control mode This servo is used as a position control servo.

Section 3.2.1

Section 3.6.1

Section 4.2

Speed control mode This servo is used as a speed control servo.

Section 3.2.2

Section 3.6.2

Section 4.3

Torque control mode This servo is used as a torque control servo.

Section 3.2.3

Section 3.6.3

Section 4.4

Position/speed control

change mode

Using an input device, control can be switched between position control and speed

control.

Section 3.6.4

Speed/torque control change

mode

Using an input device, control can be switched between speed control and torque

control.

Section 3.6.5

Torque/position control

change mode

Using an input device, control can be switched between torque control and position

control.

Section 3.6.6

High-resolution encoder

High-resolution encoder of 4194304 pulses/rev is used as the encoder of the rotary

servo motor compatible with the MELSERVO-J4 series.

Absolute position detection

system

Merely setting a home position once makes home position return unnecessary at

every power-on.

Chapter 12

Gain switching function

You can switch gains during rotation and during stop, and can use an input device to

switch gains during operation.

Section 7.2

Advanced vibration

suppression control II

This function suppresses vibration at the arm end or residual vibration. Section 7.1.5

Machine resonance

suppression filter

This is a filter function (notch filter) which decreases the gain of the specific frequency

to suppress the resonance of the mechanical system.

Section 7.1.1

Shaft resonance suppression

filter

When a load is mounted to the servo motor shaft, resonance by shaft torsion during

driving may generate a mechanical vibration at high frequency. The shaft resonance

suppression filter suppresses the vibration.

Section 7.1.3

Adaptive filter II

Servo amplifier detects mechanical resonance and sets filter characteristics

automatically to suppress mechanical vibration.

Section 7.1.2

Low-pass filter

Suppresses high-frequency resonance which occurs as servo system response is

increased.

Section 7.1.4

Machine analyzer function

Analyzes the frequency characteristic of the mechanical system by simply connecting

an MR Configurator2 installed personal computer and servo amplifier.

MR Configurator2 is necessary for this function.

Robust filter

This function provides better disturbance response in case low response level that

load to motor inertia ratio is high for such as roll send axes.

[Pr. PE41]

Slight vibration suppression

control

Suppresses vibration of ±1 pulse produced at a servo motor stop. [Pr. PB24]

Electronic gear Input pulses can be multiplied by 1/10 to 4000.

[Pr. PA06]

[Pr. PA07]

S-pattern

acceleration/deceleration time

constant

Speed can be increased and decreased smoothly. [Pr. PC03]

Auto tuning

Automatically adjusts the gain to optimum value if load applied to the servo motor

shaft varies.

Section 6.3

Brake unit

Used when the regenerative option cannot provide enough regenerative power.

Can be used for the 5 kW or more servo amplifier.

Section 11.3

Power regeneration converter

Used when the regenerative option cannot provide enough regenerative power.

Can be used for the 5 kW or more servo amplifier.

Section 11.4

Regenerative option

Used when the built-in regenerative resistor of the servo amplifier does not have

sufficient regenerative capability for the large regenerative power generated.

Section 11.2

Alarm history clear Alarm history is cleared. [Pr. PC18]

Input signal selection (device

settings)

ST1 (Forward rotation start), ST2 (Reverse rotation start), and SON (Servo-on) and

other input device can be assigned to any pins.

[Pr. PD03] to

[Pr. PD22]

Loading...

Loading...