17. FULLY CLOSED LOOP SYSTEM

17 - 20

(b) Position deviation error detection

Set [Pr. PE03] to "_ _ _ 2" to enable the position deviation error detection.

Position deviation error detection

2

[Pr. PE03]

Comparing the servo motor-side feedback position (2)) and load-side feedback position (4)), if the

deviation is not less than the set value (1 kpulses to 20000 kpulses) of [Pr. PE07 Fully closed loop

control position deviation error detection level], the function generates [AL. 42.1 Servo control error

by position deviation] and stops the motor. The initial value of [Pr. PE07] is 100 kpulses. Change the

set value as necessary.

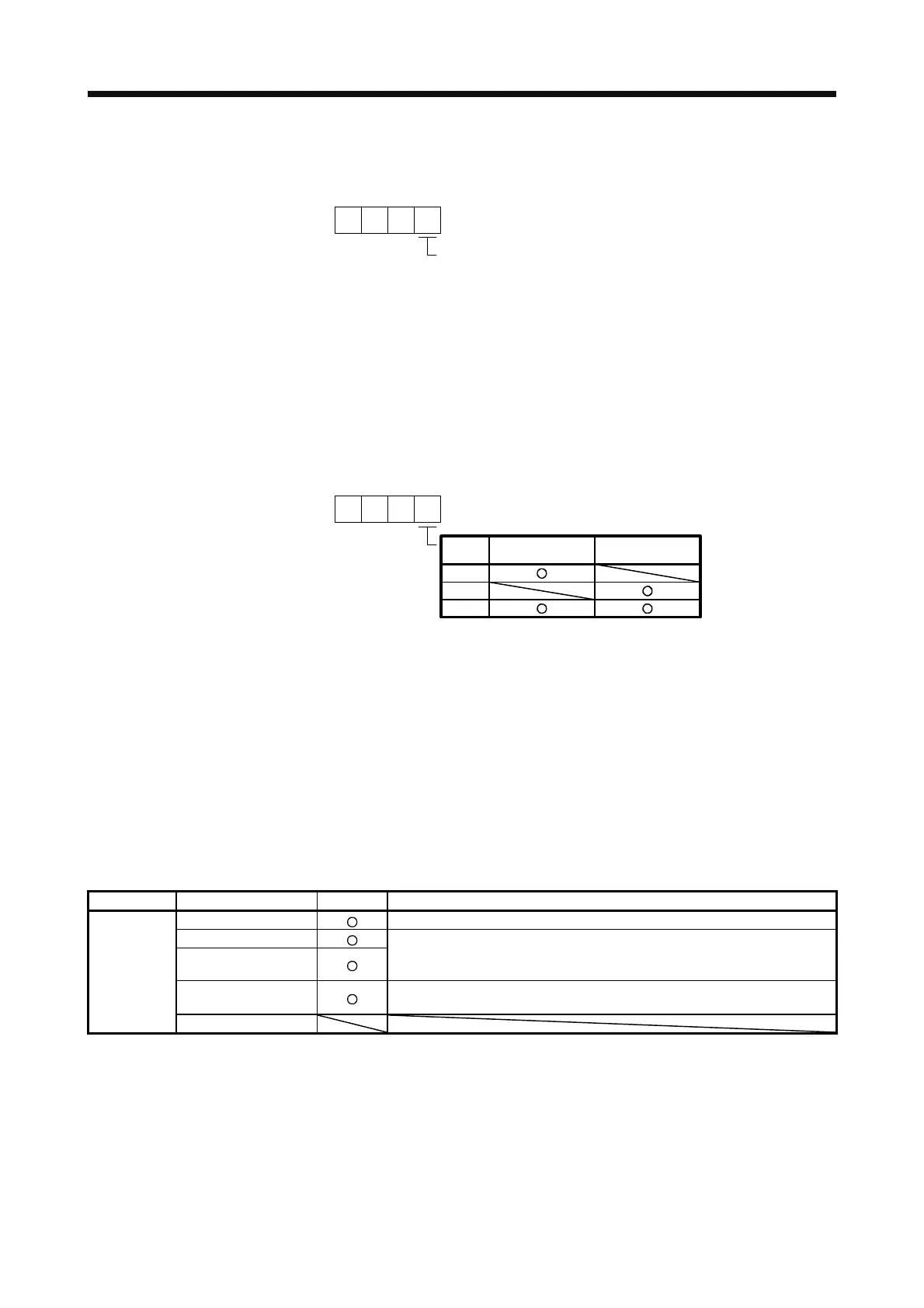

(c) Detecting multiple deviation errors

When setting [Pr. PE03] as shown below, multiple deviation errors can be detected. For the error

detection method, refer to (2) (a), (b) in this section.

[Pr. PE03]

Setting

value

Speed deviation

error detection

Position deviation

error detection

1

2

3

17.3.4 Auto tuning function

Refer to section 6.3 for the auto tuning function.

17.3.5 Machine analyzer function

Refer to Help of MR Configurator2 for the machine analyzer function of MR Configurator2.

17.3.6 Test operation mode

Test operation mode is enabled by MR Configurator2.

For details on the test operation, refer to section 4.5.9.

Function Item Usability Remarks

JOG operation

It drives in the load-side encoder resolution unit

Positioning operation

Program operation

The fully closed loop system is operated in the load-side encoder resolution

unit.

For details, refer to section 4.5.9 (5).

Output signal (DO)

forced output

Refer to section 4.5.9 (6).

Test

operation

mode

Motor-less operation

Loading...

Loading...