77 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE

ENGLISH

ENGINE MAIN PARTS

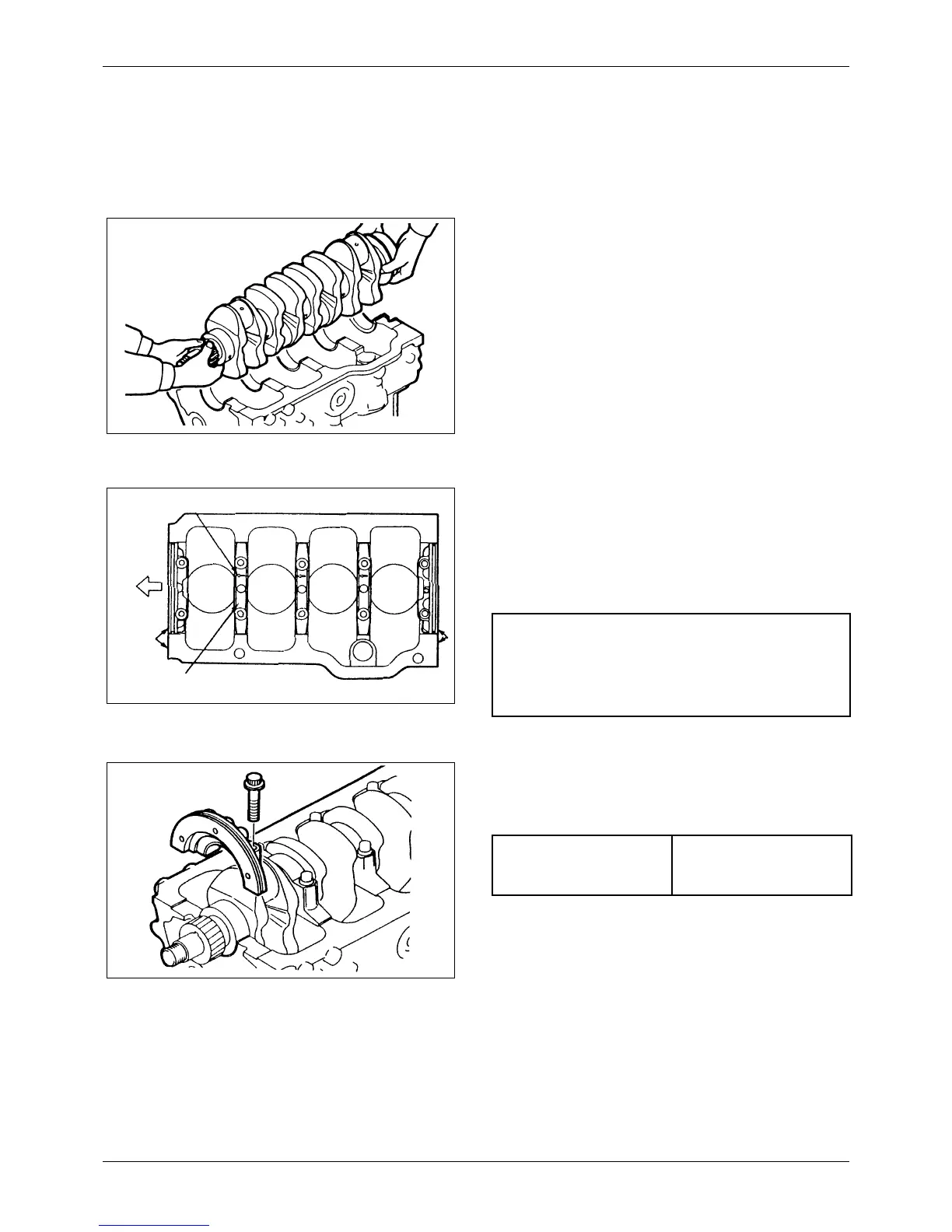

2) Install the upper and lower halves of the main

bearing having flanges in the crankcase and

main bearing cap for No.5 journal of the

crankshaft.

3) Lightly coat the inside surface of the shells

with engine oil.

3. Installing crankshaft

1) Wash the crankshaft with cleaning solvent and

blow dry with compressed air. Make sure all oil

holes in the crankshaft are clean. Check the

oil holes for condition.

2) Hold the crankshaft in a horizontal position by

using a hoist, and carefully put it in the

crankcase.

3) Lightly coat the journals with engine oil.

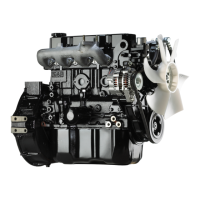

4. Installing main bearing caps

Install the main bearing caps in position so the

“front” mark (arrow) on the cap is toward the front

of the engine and the number on the cap is the

same as the number on the crankcase on the left

side of each main bearing cap.

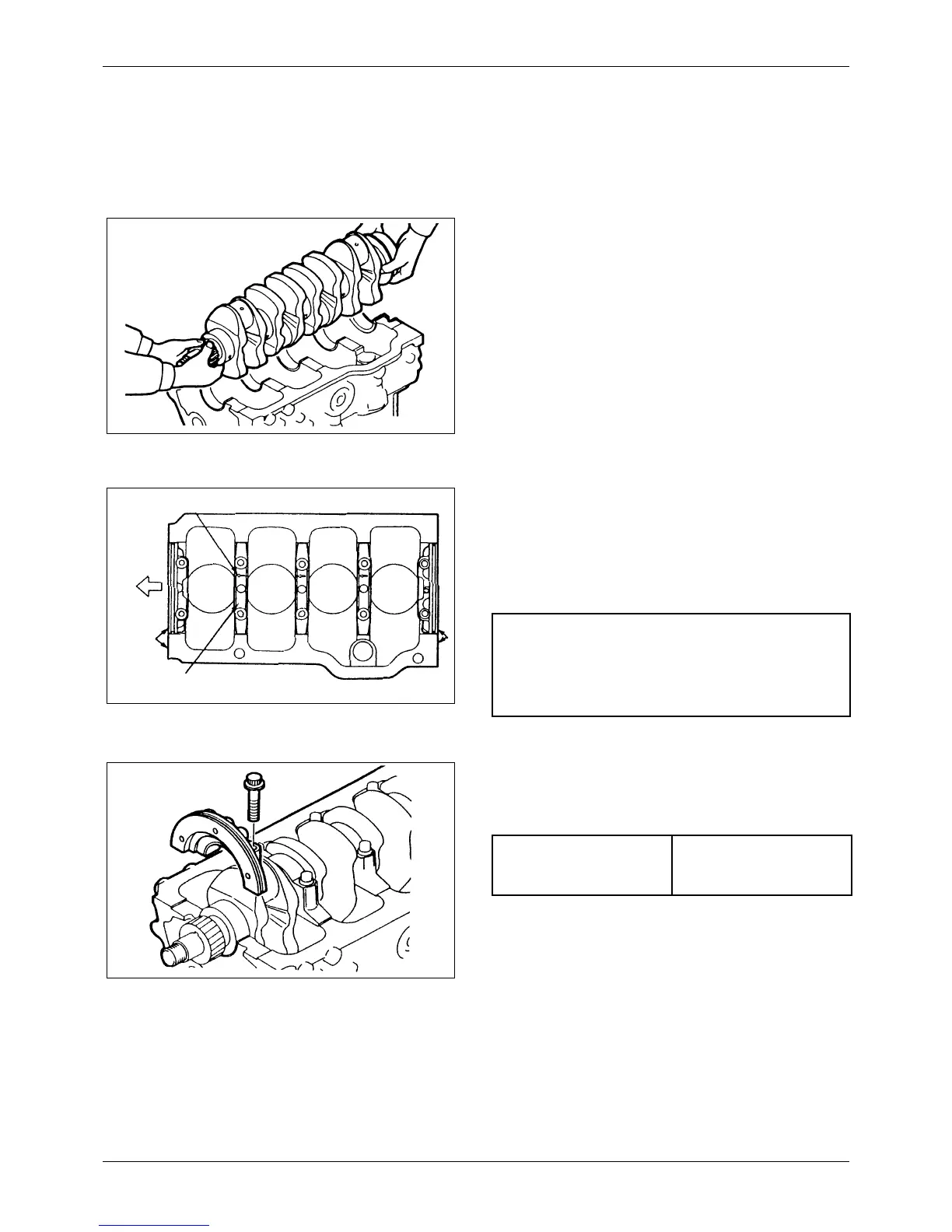

5. Tightening main bearing cap bolts

Tighten the main bearing cap bolts evenly to the

specified torque.

Figure 138 Installing crankshaft

Figure 139 Installing main bearing caps

Cap number

Front of

engine

Flush

“Front” mark

NOTE

The end faces of No.1 and No.5 bearing caps must

be flush with the end faces of the crankcase.

Figure 140 Tightening main bearing cap bolts

Tightening torque

83 ± 5 N·m

(8.5 ± 0.5 kgf·m)

[61 ± 4 lbf·ft]

Loading...

Loading...