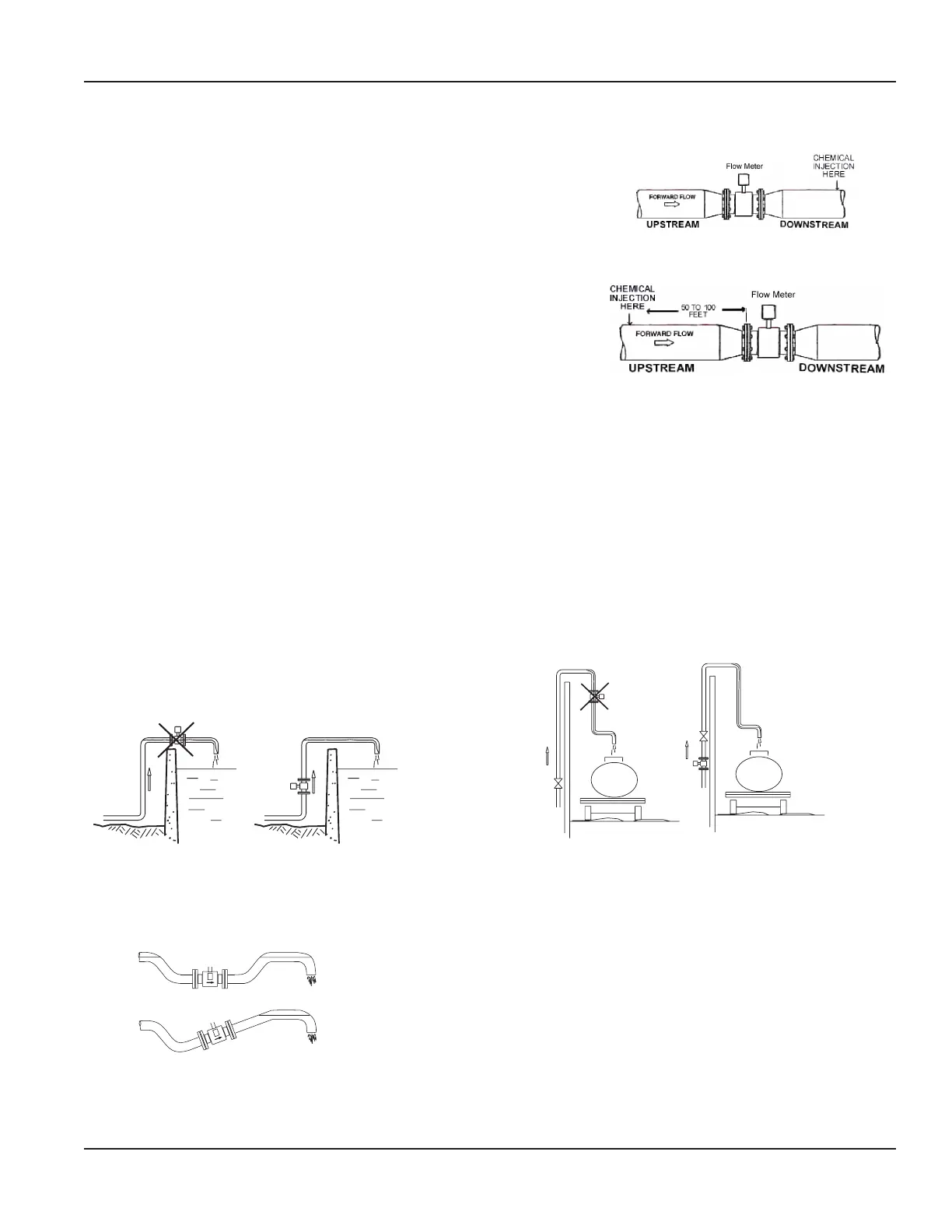

Chemical Injection Applications

For water line applications with a chemical injection point, install the meter

upstream of the injection point. This eliminates any meter performance issues.

Figure 15: Chemical injection point downstream of meter

If a meter must be installed downstream of a chemical injection connection,

the distance between the flange and the injection point should be between

50…100 feet (15…30 meters). The distance must be long enough to

allow the water or chemical solution to reach the meter in a complete,

homogeneousmixture.

Figure 16: Chemical injection point upstream of meter

If the injection point is too close, the meter senses the two different conductivities for each liquid. This will likely result in

inaccurate measurements. The injection method—spaced bursts, continuous stream of drips or liquid or gas—can also affect

downstream readings by the meter.

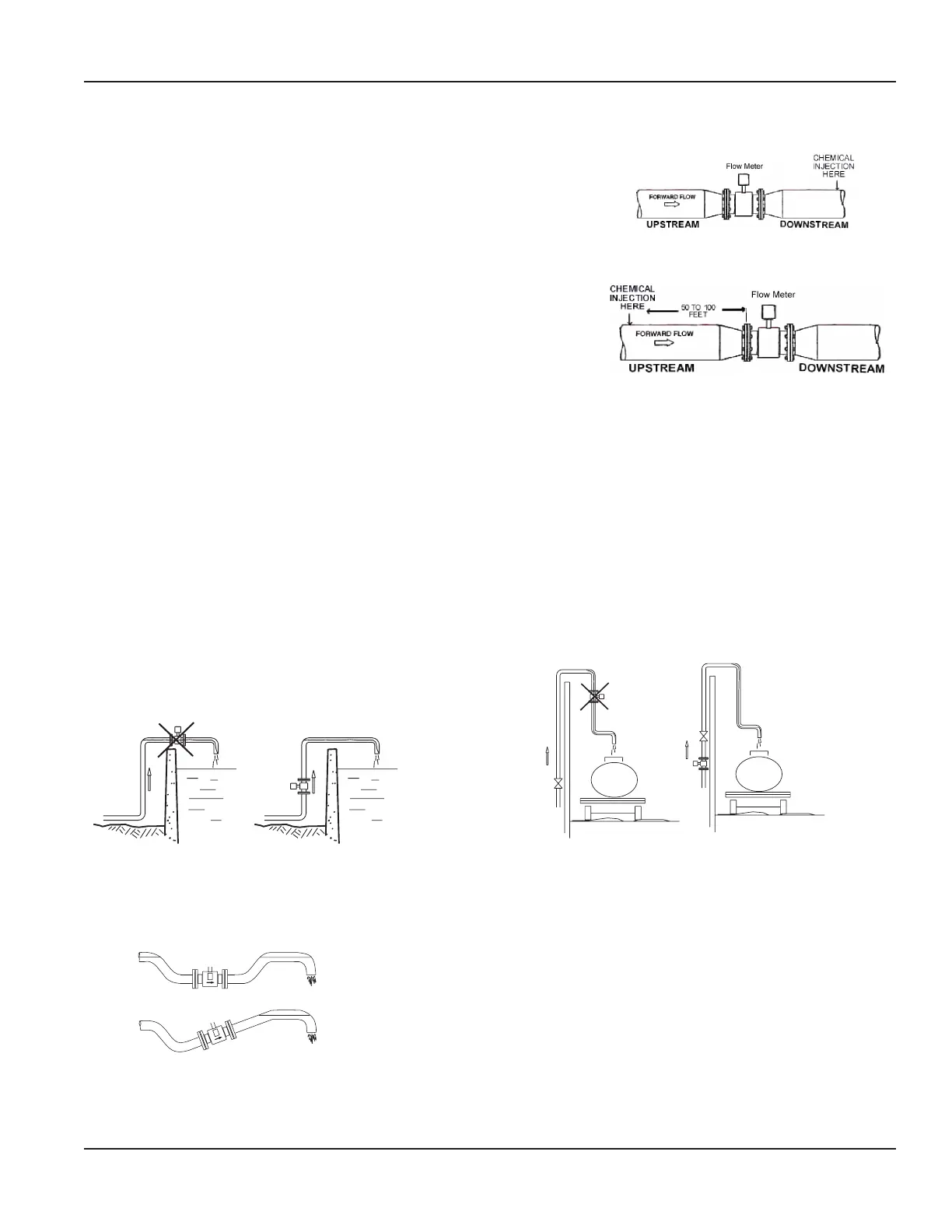

Partially Filled Pipe Situations

In some locations, the process pipe may be momentarily only partially filled. Examples include: lack of back pressure,

insufficient line pressure and gravity flow applications.

To eliminate these situations:

• Do not install the meter at the highest point of the pipeline.

• Do not install the meter in a vertical, downward flow section of pipe.

• Always position the ON/OFF valves on the downstream side of the meter.

FLOW

FLOW

FLOW

WRONG

FLOW

RIGHT

Figure 17: Meter placement

Do not install in a vertical, downward position. Position "On/Off" valves on downstream side.

Figure 18: Position valves on downstream side

To minimize the possibility of partially full pipe flows in horizontal, gravity or low pressure applications, create a pipe

arrangement that allows the detector to remain full of liquid at all times.

Figure 19: Pipe positioned to keep water in detector

Meter Location, Orientation and Applications

Page 13 March 2020 MAG-UM-00379-EN-07

Loading...

Loading...