• WE NORMALLY DELIVER THE METER IN ACCORDANCE WITH PROTECTION CLASS IP 67. IF YOU HOWEVER REQUIRE A

HIGHER PROTECTION CLASS, THE AMPLIFIER IS TO BE INSTALLED SEPARATELY FROM THE DETECTOR. IF REQUESTED,

WE CAN ALSO DELIVER THE DETECTOR IN IP 68.

• LES JOINTS DE CORPS NE DOIVENT PAS ÊTRE ENDOMMAGÉS ET ÊTRE EN BON ÉTAT.

• TOUTES LES VIS DE CORPS DOIVENT ÊTRE FERMEMENT SERRÉES.

• LE DIAMÈTRE EXTÉRIEUR DES FILS DE CÂBLAGE UTILISÉS DOIVENT CORRESPONDRE AUX ENTRÉES DE CÂBLE (POUR

M20 DIAMÈTRE 5…13 MM). DANS LES CAS OÙ L'ENTRÉE DE CÂBLE N'EST PAS UTILISÉE, METTEZ UNE FICHE ISOLANTE.

• SERREZ LES ENTRÉES DE CÂBLE.

• SI CELA EST POSSIBLE, DIRIGEZ LE CÂBLE VERS LE BAS. ÉVITEZ QUE DE L'HUMIDITÉ NE PÉNÉTRE DANS L'ENTRÉE DE

CÂBLE.

• LE COMPTEUR OFFERT EST NORMALEMENT CONFORME À LA CLASSE DE PROTECTION IP 67. CEPENDANT, SI

VOUS EXIGEZ UNE CLASSE DE PROTECTION SUPÉRIEURE, L'AMPLIFICATEUR DOIT ÊTRE INSTALLÉ SÉPAREMENT DU

DÉTECTEUR. SUR DEMANDE, LE DÉTECTEUR PEUT ËTRE OFFERT EN IP 68.

METER GASKETS AND GROUNDING

Gasket and grounding requirements must be considered when determining the meter location, orientation and application.

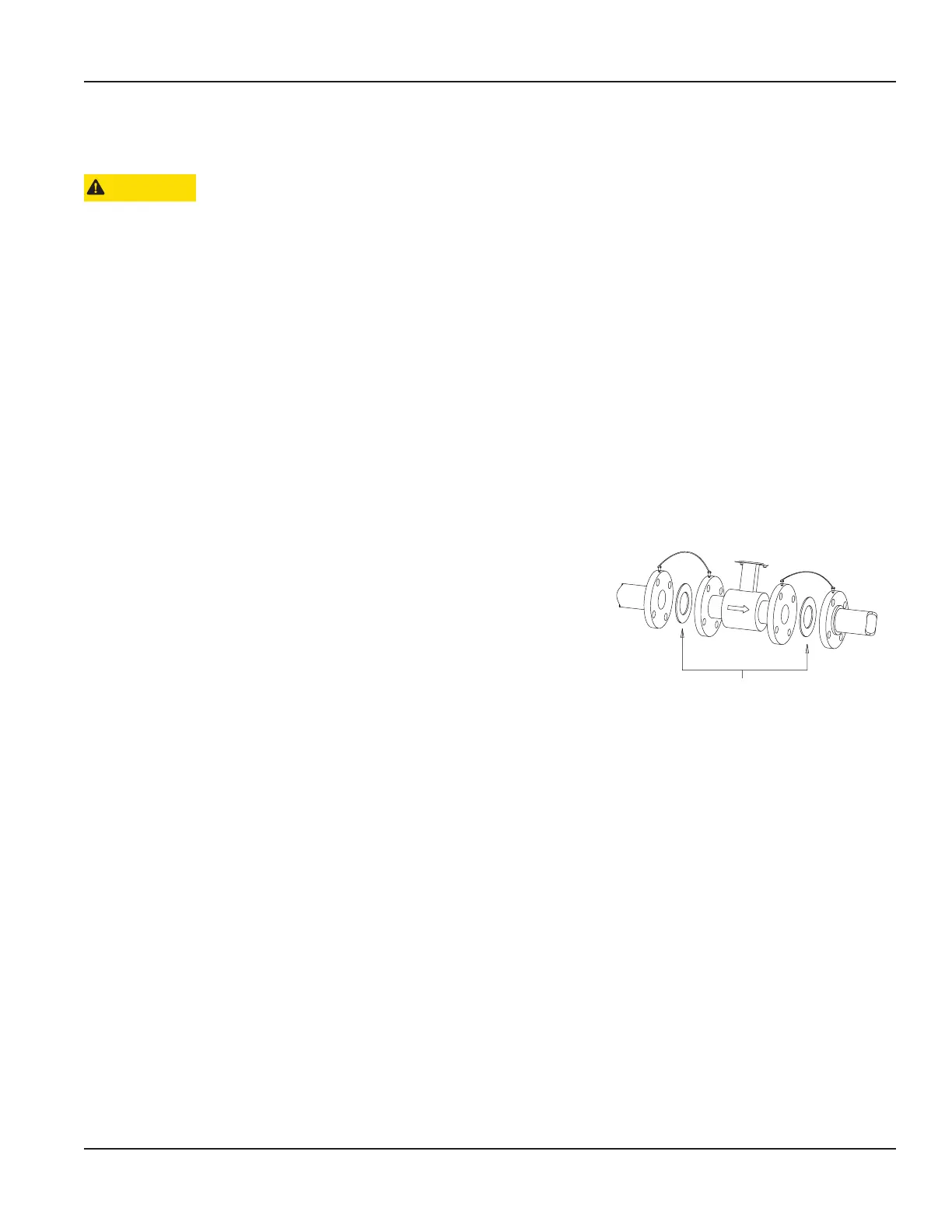

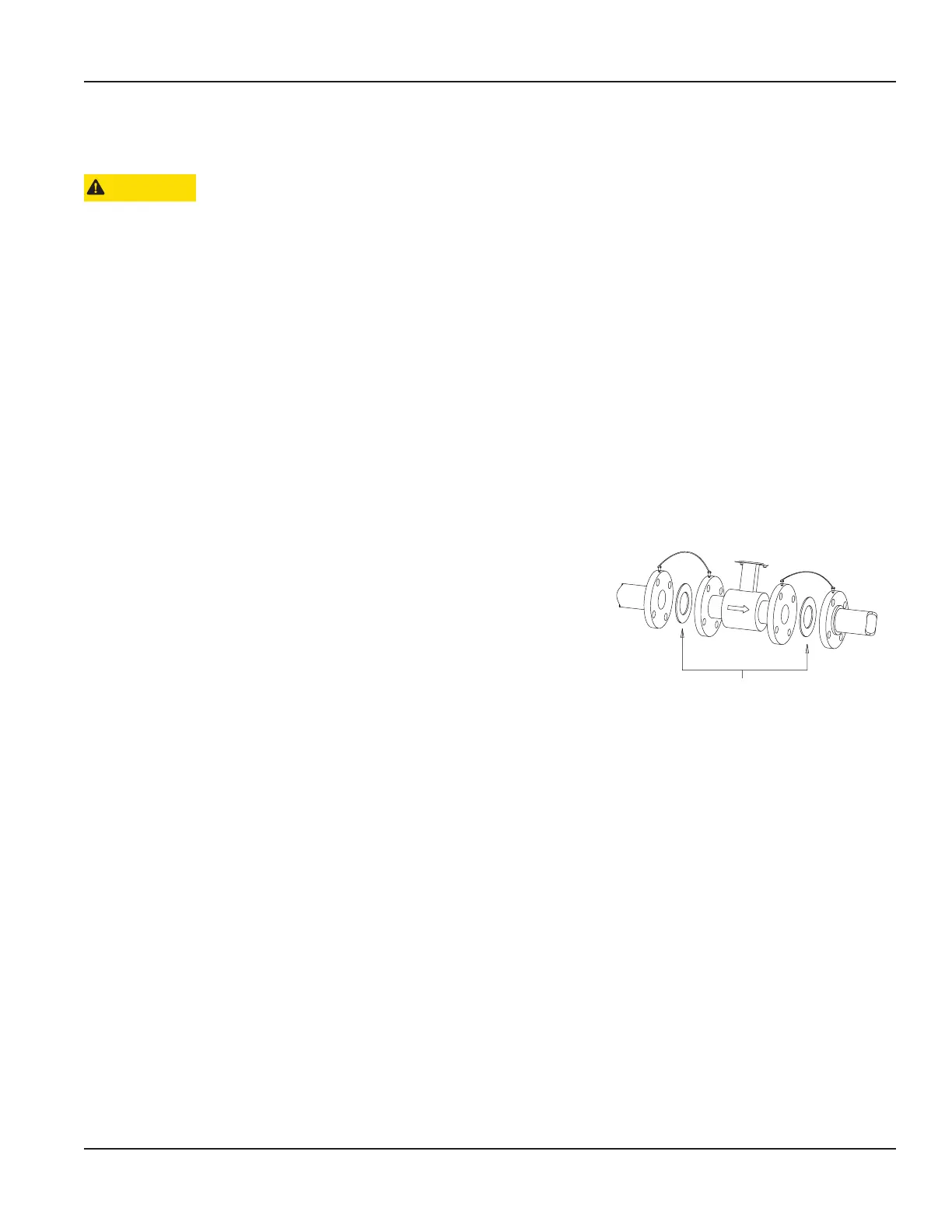

Meter/Pipeline Connection Gaskets

You must install gaskets (not provided) between the detector's isolating liner

and the pipeline flange to ensure a proper and secure hydraulic seal. Use gaskets

that are compatible with the fluid. Center each gasket on the flange to avoid flow

restrictions or turbulence in the line.

During installation, do not use graphite or any electrically conductive sealing

compound to hold the gaskets. This could compromise the accuracy of the

measuring signal.

If you are using a grounding ring in the detector/pipeline connection, place the

ring between two gaskets. (See “Pipelines with Cathodic Protection” on page16.)

Figure 20: Meter/pipeline connection gaskets

Meter Grounding

Process pipeline material can be either electrically conductive (metal) or not electrically conductive (made of or lined with

PVC, fiberglass or concrete).

IMPORTANT

It is essential that the meter amplifier’s input ground (zero voltage reference) be electrically connected to the liquid media and to a

good, solid earth ground reference.

Conductive Pipe Grounding

To achieve an adequate ground, the meter body MUST be electrically connected to the liquid media. The meter flanges are

provided with grounding bolts for this purpose.

If the pipe material is electrically conductive, simply install grounding straps between these grounding bolts and the

mating flanges.

To provide a good electrical connection at the mating flanges, we recommend that you drill and tap the flanges and install a

grounding screw (not provided).

Grounding straps must be copper wire, at least 12 AWG size. They must be connected on both sides (inlet and outlet) of the

detector and to a local, earth ground.

Meter Gaskets and Grounding

Page 15 March 2020 MAG-UM-00379-EN-07

Loading...

Loading...