7. Final Installation Procedure

After finished installation a load test (according to

ISO 10535:2006) must be performed. Maximum

Safe Working Load shall be applied on all

mounted attachments. Perform at least six lifts

(lift height approx. 15 cm/6 inches) SWL at min. 6

randomly selected points along the rail.

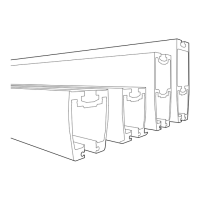

7.1 Load test: Straight Rail System

Lift the load approx. 15cm to apply the maximum

load. Travel the applied load along the rail from

one end stop to the other end stop, with a 10

second pause under each attachment point. Travel

as the dashed line shows in picture.

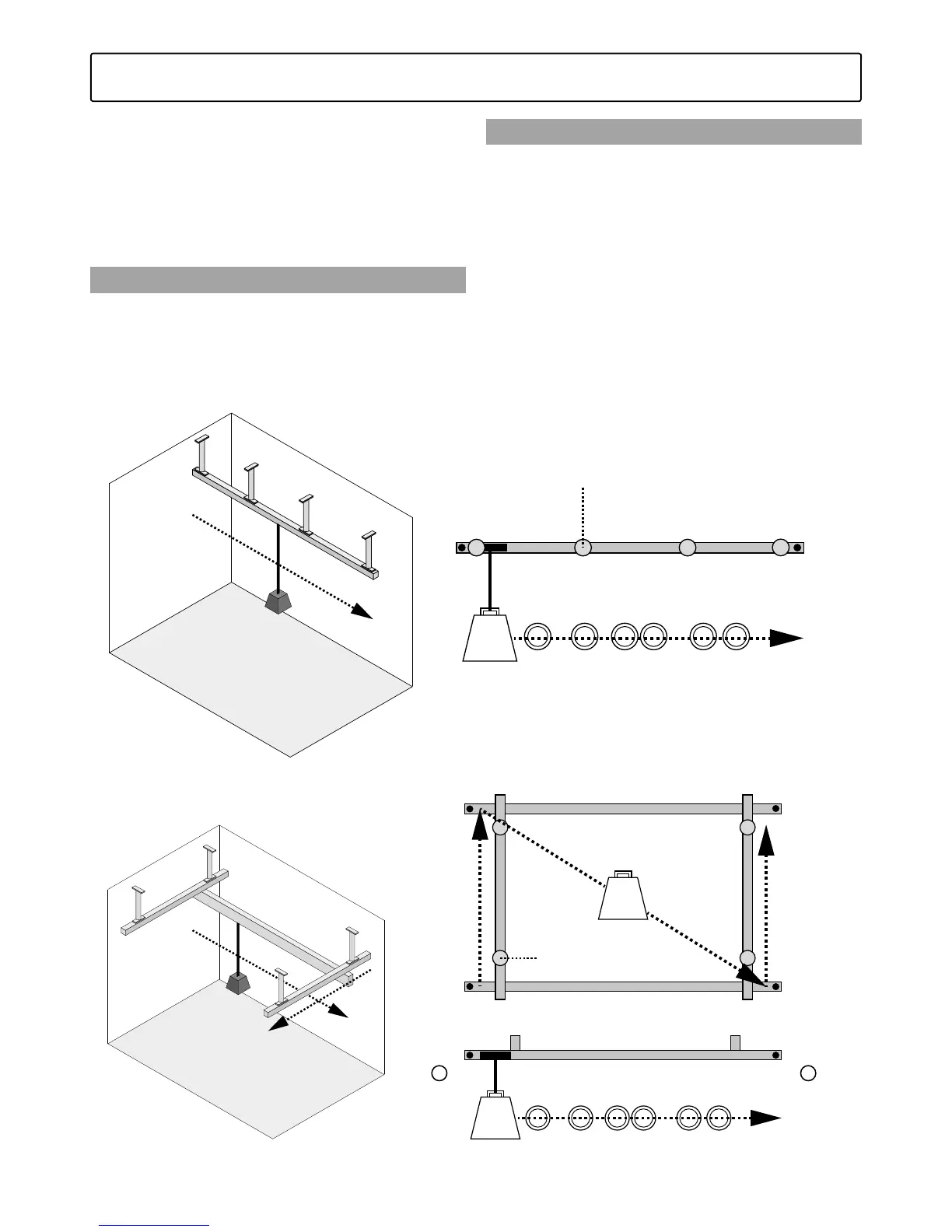

7.2 Load test: Traverse Rail System

Apply the maximum load for the installed

overhead rail system. Place the carriage with the

applied load at the end stop of the secondary rail

(1). Move the secondary rail, with a pause under

each attachment point, from one end stop to the

other end stop of the first primary rail. Continue

by moving the applied load diagonally through

the centre of the system over to the other side, as

the dashed line shows. Now continue by moving

the secondary rail with the applied load, from (2),

with a pause under each attachment point, from

one end stop to the other end stop of the second

primary rail.

MAX

LOAD

Pause under Attachments

Rail

End StopEnd Stop

Lift at 6 random points

Pause under

Attachments

MAX

LOAD

MAX

LOAD

Secondary Rail

End Stop

End Stop

End Stop

Primary RailPrimary Rail

Lift at 6 random points

End Stop

End Stop

End Stop

1 2

Figure: Load test: Straight Rail System

Figure: Load test: Traverse Rail System

Loading...

Loading...