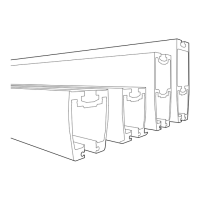

6. Installation methods

The rail system can only be

installed by certified personnel in

accordance with applicable

installation instructions.

Etac is only responsible for the

system if the rail system with trol-

ley and/or lifting motor has been

supplied by Etac and is installed by

authorised staff.

The lifter’s SWL may NEVER exceed

the SWL of the rail system.

There may never be installed more

than one lifting motor per rail

system.

The SWL of the rail system must be

clearly marked on the rail.

All rail systems must be provided

with end stops and end caps to

prevent the trolleys from running

off the system.

Etac recommends that annual

inspections of the system be carried

out according to “Check points for

periodic inspection”.

Please contact Your Service Partner

or Molift by Etac Customer Support

in case of defects to the rail system.

Tools needed for installation and surveys

Survey tools:

Digital camera

Laser range meter

Measure tape: minimum 5 meter length

Stairs

Flash light

Installation tools:

Security equipment (gloves, helmet, boots, ear

protection plugs)

Laser range meter and folding rule

Laser leveler

Working platform / stairs

Lifting equipment for profiles

Saw and table for cutting profiles

Electric drill (battery powered)

«standard» hand tooling

Lights

Fixing components for MRS

Etac Supply Gjøvik does not supply fixing compo-

nents for Molift Rail System.

Fixing component examples:

- Mechanical expansion anchors

- Chemical anchors

- Concrete screws

- Wood screws

The Etac certified installer is responsible for provid-

ing correct fixing components to each project.

Building structure and material on site must be

evaluated before choosing fixing components. The

details and knowledge of this should be estab-

lished during site survey. The fixing components

must meet the requirements in ISO 10535:2006

described in chapter “2.4 Point loads”.

The final installation procedure will verify the

installation before it is taken into use.

Loading...

Loading...